Is Poor Power Quality Zapping Your Profits?

New technology allows processors to monitor electrical power in their plant and diagnose hiccups so they can more intelligently find a solution.

For D.J. Parry, it was a real head-scratcher. The operations manager of stretch-film processor Goodwrappers Inc. was first made aware of some odd goings-on in his Baltimore plant in February. His third-shift team told him of output losses resulting from his two extrusion lines slowing down, seemingly out of nowhere. Moreover, his water-circulation units, which are used to cool his extruders, were conking out altogether.

Had gremlins been running amok in Parry’s plant in the wee hours of the morning?

Fortunately for Goodwrappers, Parry had agreed to be a beta site for new technology aimed at monitoring power quality in plastics processing plants. So with just a few mouse clicks, Parry noticed that his plant was experiencing a drop in power at 2:30 AM—like clockwork. Somehow, at that time, something on his power grid was sucking up more juice than usual, and his production lines were impacted.

Among plastics processors, $9.6 billion a year ‘walks out the door’ as a result of poor power quality.

Parry got his local utility involved, showing them graphs that charted the power dip. The utility did some investigating, and as it happens, the power problem had nothing to do with gremlins at all. The explanation was far more plausible: An expanding metal-recycling plant nearby was firing up its new magnetic separators at 2:30 AM on the dot, causing an electrical sag that impacted the Goodwrappers production operation a short distance away. The power company responded to Parry’s problem by increasing power to his building from 650 amps to 900 amps.

The technology at Goodwrapper’s plant, which was connected to its main power-supply line, is the latest offering from MachineSense, Inc./Prophecy Sensorlytics, Baltimore, which since NPE2015 has been offering “machine-wearable” predictive-maintenance sensors and software for vacuum pumps and blowers.

This new offering is called the Power Analyzer, and it takes aim at poor power quality, a problem that costs the U.S. economy up to $188 billion a year, according to the Electrical Power Research Institute (EPRI). What’s more, the EPRI estimates that 80% of power- quality problems are generated from issues within a facility.

Among plastics processors, this accounts for $9.6 billion a year “walking out the door,” notes Conrad Bessemer, CEO of Novatec Inc., a MachineSense/ Prophecy licensee for pumps and blowers supplied with predictive-maintenance sensors and software. “In plastics processing, it’s estimated that material accounts for 60-70% of a company’s overall expenses,” Bessemer says. “And most processors have wisely examined every possible technique to reduce those costs, including using third-party services to negotiate prices on their behalf. Labor is a big expense too, of course, and processors in growing numbers are making more use of robotics and automation so they can reallocate the people they have to more productive functions.”

But energy, which by some estimates accounts for up to 15% of overall expenses in a typical plastics processing operation, is by and large ignored, according to Bessemer. Why? Mostly because it’s not understood, he maintains.

“People are unaware of the real reason for ‘gremlins’ in their power system and generally just accept them,” says Bessemer. “Generally speaking, people have a greater understanding of mechanical issues than electrical. As a result, a lot of money is being wasted. We’ve had customers come to us to exchange motors, circuit boards, display boards, and the like on a yearly basis. For certain, their problem is not with these components, but in the power that’s feeding them. So they are not really dealing with the cause of the problem, but its effect.”

While there are various sensors and instruments on the market that are used to test power quality on industrial equipment, they simply capture results at that moment in time, since they are temporary, on-the-spot devices, notes Jim Zinski, president of MachineSense/Prophecy. “Issues with power quality don’t always occur when you want them to, when you are checking your motors with portable instruments. Really, you want to monitor your major assets on a 24/7 basis, get trends on what’s going on, and identify issues before they start affecting your machines and your business.”

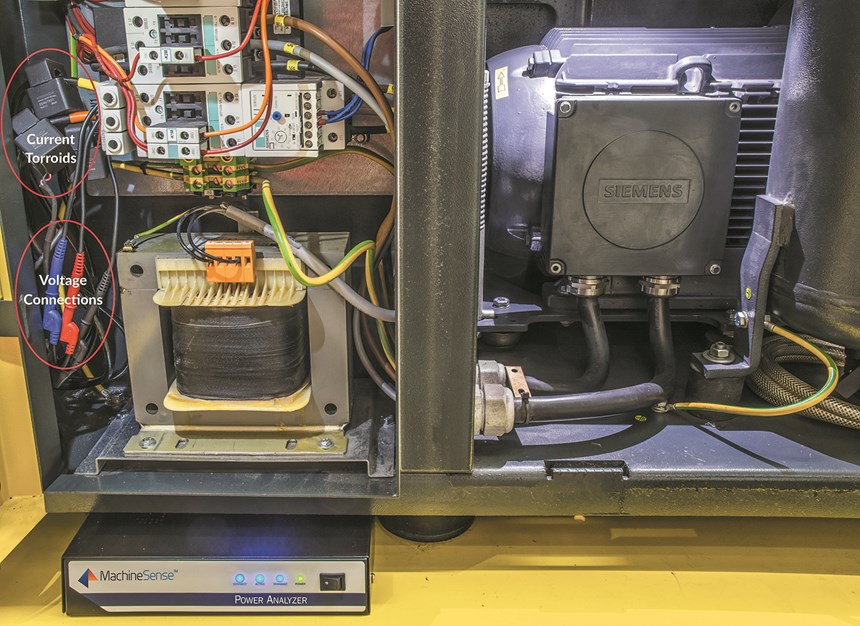

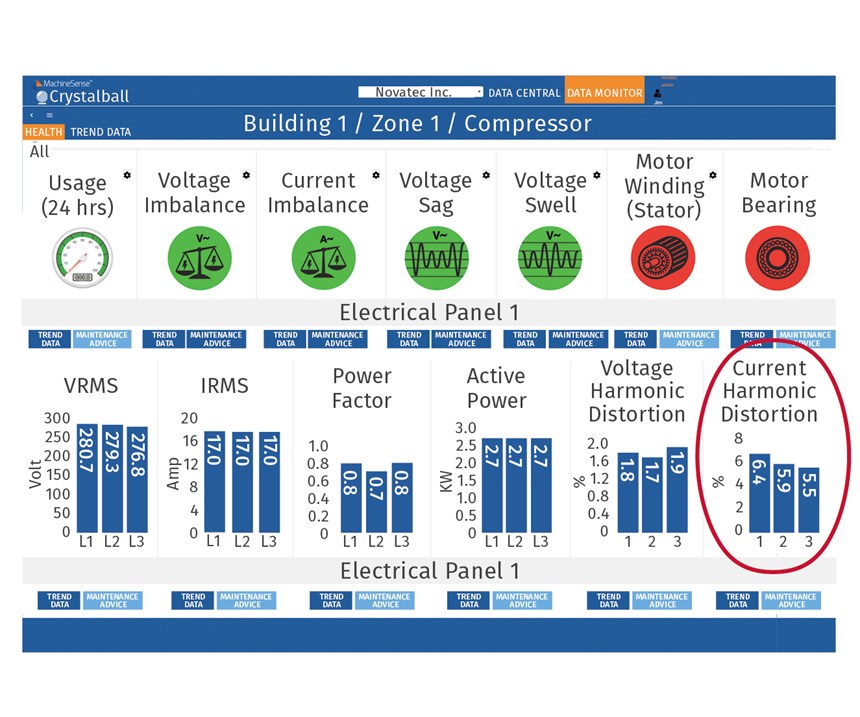

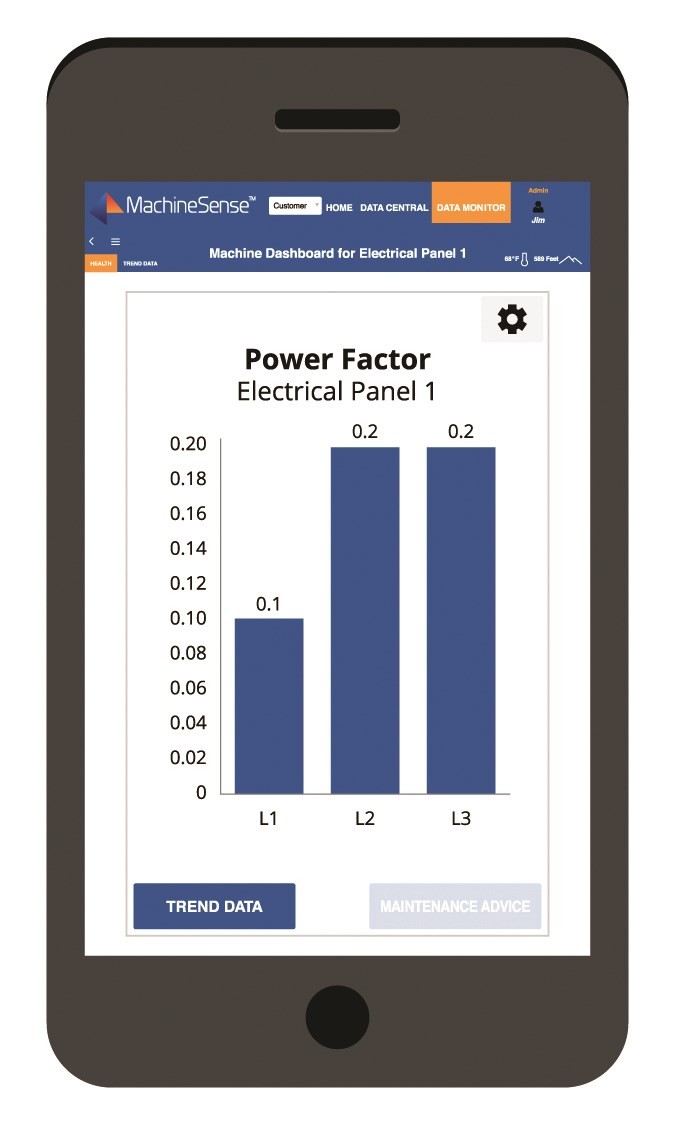

The MachineSense Power Analyzer aims to do just that. The package consists of clip-on toroid sensors and voltage leads that attach to the input power line and constantly monitor the supply line. Sensor data is transmitted by the on-board MachineSense Datahub via Wi-Fi or Ethernet to a local router and to MachineSense’s cloud infrastructure. The Power Analyzer measures and analyzes voltage and current on all three phases. Metrics are provided on power factor, active power and energy, voltage and current harmonic distortion, voltage and current imbalance, sag/swell events, and power usage.

The MachineSense proprietary analytics algorithm tracks and compares the collected data against a baseline to determine the overall component health, trending components

such as motor bearings and stator windings as well as heating elements, explains Biplab Pal, MachineSense/Prophecy’s chief technology officer. Phase imbalance can be detected and reported, as well as current and historic electrical power consumption. Besides the visualization of critical operating metrics, the Power Analyzer predicts and alarms for pending machine and component failures to significantly reduce unscheduled equipment downtime, Pal says.

The Power Analyzer monitoring solution includes MachineSense Crystalball software, which enables the user to set up alarms and alarm recipients, provides six months of historic data with trend lines that show equipment performance, as well as serving as a dashboard for all monitored assets, by department or plant.

Says Zinski, “When power lines are put in, not many processing plants put a tremendous amount of thought in determining where they will be placing equipment that will require a lot of power, as opposed to where they will be placing equipment that draws less. As a result, in

a typical plastics processing plant there will be lots of surges and swells. These kinds of problems tend to get worse when a plant expands.”

The Power Analyzer is designed to be simple and easy to understand, taking into account the fact that a scant few processors have electrical engineers on staff. Adds Parry of Goodwrappers, “I’m getting very high-level data presented in a very simple way.”

Unlike the firm’s other predictive-maintenance products, the Power Analyzer is a diagnostic tool and does not offer solutions to a particular problem. MachineSense/Prophecy Sensorlytics has teamed up with service companies that have expertise in the area of power quality. “What we are giving our customers is the ability to show the equivalent of an x-ray to an expert at one of our service companies, which will use it to make recommendations on a solution,” Zinski says. Solutions could include adding such devices as surge protectors or extra capacitors, adds Pal.

The Power Analyzer is available for purchase online at the MachineSense website and will also be distributed through service companies. Prices range from $1195 to $1295, depending on amperage draw. The data plan is free for the first six months, and then costs $180/yr. Energy monitoring is standard; analytics for motors and heater banks are optional.

Read Next

‘Machine Wearables’ Predict Health of Vacuum Pumps & Blowers

Conveying systems now come with predictive-maintenance technology at no upcharge.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)