Is Your Die Flow Changing Despite Following All the Correct Formulas?

Maybe the problem is that you're starting up with a dry die. Here are tips to solve this issue.

One of the most common problems extrusion plants have is flow shifting in the die tooling, especially after starting up. This can occur even when the run history and setup documents are followed and painstakingly reviewed to the letter. What should be a quick changeover turns into the dreaded scrap nightmare. What went wrong?

Sharing knowledge in tool building has historically been taboo. Toolmakers had their little notebook of cheat sheets on land ratios and what drawdown to use with each material. In the end, each tool made from any given tool shop was different. Fast forward and shops are run differently, with most shops running toward one common standard. More literature on tool design is available than in the past, so what is causing the flow shift?

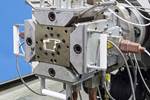

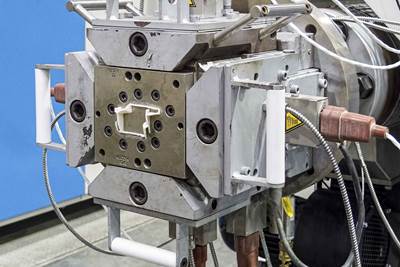

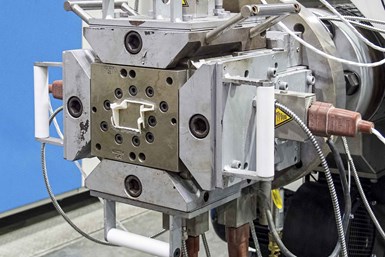

If you start up with a dry profile die, you may wind up having flow instability, which could lead to a host to quality issues. Photo: Matthew Naitove

Let’s troubleshoot and look at the steps which may be causing the flow shift.

- Pressure: Back pressure is usually monitored and recorded in most extrusion shops but is seldom manipulated to optimize the process. When a new tool is tuned, the pressure is recorded as a standard and not questioned if it is correct. Many articles have been written on the how low head pressure can cause poor screw performance in a single-screw extruder. What we are looking for in pressure as it pertains to flow shift in the die is consistency. A consistent pressure should always be presented to the die for stability.

Before starting up, lubricate all components of the tooling while hung on the extruder.

- Melt Temperature: Much like pressure, the melt temperature should always be presented to the die in a consistent manner to ensure stability.

- Die Land: If the die-land ratio is not sufficient, the lowered residence time (along with a lack of back pressure) will create flow shift and instabilities. Many shops tend to start out light on the land ratio and do not have sufficient land for stability after the land is reduced in the development process. Be steel safe and err on the extra landside. As an added benefit, land reduces the swell of the material as it exits the die. Most materials call for a 15:1 land ratio or greater.

Lubricating the die (arrow pointing to the wall to be lubricated) will sometimes improve drag flow and eliminate flow shift. Photo: Tim Groth

- Heater Bands: In a past article, I wrote about the five heater band principles being one of the most overlooked variables of the extrusion process. Let’s assume you have read the article and corrected any deficient principles of the five and heat to the die is correct and consistent. At this point, you may want to go back and read that article and do a double check on the heater bands.

Ok, so what if the pressure, melt temperature, die land and heater bands all check out, but the dreaded flow shift happens anyway. There is one more thing to do, which many times will stop flow shift: Lubricate the tooling.

Lubrication Can Improve Drag Flow

The cavity of a streamline plate does not fill equally because the channel lengths are different, with varying lengths of drag flow. The bigger the tool, the larger the cavity to fill and the greater the potential for problems. Lubricate all components of the tooling while hung on the extruder, before starting up. The initial pressure will be reduced but will increase and reach a stabilization point. Many times, the improved drag flow will eliminate the flow shift issue.

ABOUT THE AUTHOR: Tim Groth has more than 37 years of hands-on extrusion experience, specializing in design for extrudability, tooling design, troubleshooting, material selection, plant setup, training of engineers and setup technicians, and practicing Lean Manufacturing principles. He is currently director of engineering for consulting company Extrusion Solutions North LLC, Hastings, Minn. Contact: 651-357-0814; timtgroth@gmail.com.

Related Content

Fully Automated Extrusion Process Enables Use of Composites for Manufacturing Pressure Tanks

Amtrol was looking for a more cost-effective means to produce thin-wall liners for a new line of pressure tanks. With the help of a team of suppliers, they built one of the world’s most sophisticated extrusion lines.

Read MoreCooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Read MoreUnderstanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreRead Next

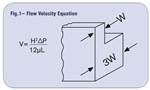

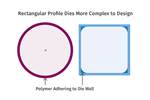

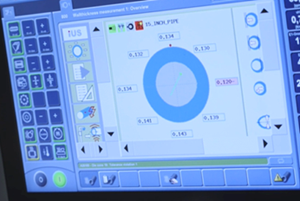

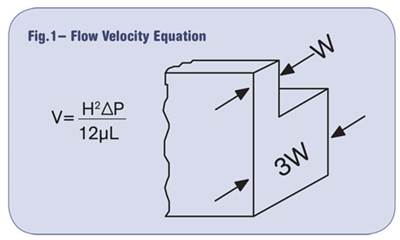

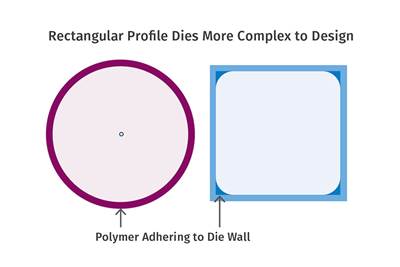

Tooling: The Science of Profile Die Balancing

In our last column, we discussed the five things profile extruders need to know about profile die design—proper land length, land-length ratio, drawdown, considerations for sensitive materials, and decompression.

Read MoreIs Your Profile Die the Problem? Or Is It the Heaters?

When a profile is not being extruded to the tolerances of previous runs, the die is often suspect—but the real problem may be the heaters. Learn the five heater-band principles before you do any profile die work.

Read MoreExtrusion: Follow These Tips to Get Profile Die Design Just Right

Calculating polymer flow is fairly straightforward when designing a die for a simple round profile, but as the shapes get more complicated these calculations can get extremely challenging. Here’s what you need to consider.

Read More