Polyurethanes: Fine-Tuning 'Green' Foams

With the switch to ‘cleaner’ blowing agents nearly complete, the priority now is tweaking foam formulations for optimal performance and cost.

The conversion to “cleaner” blowing agents in the polyure-thane foam business is largely done, and now much effort is being directed toward optimizing formulations to deliver better foams that are also easier to process and lower in cost. The latter goal is particularly challenging at a time when industry has been bombarded with un-precedented increases in materials and energy prices. The replacement blowing agents also have their own performance problems to solve in areas such as system compatibility, flowability, insulation value, and dimensional stability.

Achieving cost savings in “eco-friendly” PUR formulations while aiming to meet the market’s performance demands was a prime focus at the recent Polyurethanes 2005 Technical Conference and Trade Fair in Houston, sponsored by the Alliance for the Polyurethanes Industry.

Many presentations addressed rigid foams for building and construction, where the goal is to reduce blowing-agent costs and foam densities while retaining performance. Speakers discussed new polyols and surfactants aimed at achieving those ends. Upgrades to a popular boardstock laminator promise less downtime for maintenance.

News in the automotive sector included the latest in spray-in-mold PUR skin technology, and novel non-fugitive additives that significantly reduce VOCs during and after production of car seats.

Also discussed was innovative modular tooling that offers cost savings and flexibility in production of refrigerators and freezers.

Update on blowing agents

The conversion to blowing agents with zero ozone-depletion potential (ODP) is now accomplished in nearly all the major rigid foam sectors, most of which had relied on HCFC-141b as the leading first-generation replacement for now-banned CFCs.

Today’s leading blowing agents include hydrofluorocarbons—mainly HFC-245fa ($4/lb) and, to a lesser extent, HFC-134a ($2/lb). They are typically used with high water levels for co-blowing with CO2. A second major category are hydrocarbons—isopentane, n-pentane, and cyclopentane (50¢ to 90¢/lb). There is also the newer methyl-formate based Ecomate from Foam Supplies, Inc., offered alone or blended into systems and priced in the same range as pentanes. Ecomate is said to provide insulation between that of high-performance HFC-245fa and pentanes.

HFC-245fa, sold as Enovate 3000 by the sole North American producer, Honeywell International, is dominant in pour-in-place appliance insulation (refrigerators and water heaters) and is also leading in rigid spray-foam insulation for walls, roofs, tanks, and spas.

The more cost-sensitive polyisocyanurate (PIR) boardstock insulation sector, primarily for commercial roofing, has gone over to pentanes.

One exception to this overall conversion is metal-faced foam panels, where the use of low-ODP HCFC 22 and 142b are still allowed, although EPA aims to end that by 2010. Still, industry sources maintain that significant conversion already has taken place in this sector, primarily to pentanes, although HFC-245fa is also a candidate.

At the conference, Foam Supplies reported that its Ecomate, which has been used in the past four years for insulating drinking-water dispensers and large coolers, now is finding application in pour-in-place applications such as door panels. Working with some major polyol and surfactant suppliers, the company sees potential in other rigid foam sectors, such as replacement of pentanes in boardstock; in spray foams, where the cost of HFC-245fa is a concern; and perhaps even in the more conservative appliance sector.

According to the company, Ecomate’s high solubility, low molecular weight, high blowing efficiency, and low volatility allow for much lower use levels than either HFC-245fa or HCFC-141b. For example, a system that used 15% HCFC-141b may need only 5% to 6% Ecomate to achieve the same density.

No matter which blowing agent is used, understanding what happens to it during processing is of keen interest to foam formulators. “Finding out how much of the blowing agent is in the polymer matrix and how much remains in the foam cells is critical to the optimization of a formulation, and a crucial determinant of the foam’s properties,” explains Mary Bogdan, principle scientist in the Enovate Technical Service and Application group at Honeywell’s research laboratory in Buffalo, N.Y.

Honeywell researchers determined that there is no single current analytical technique that can be easily performed to quantify the blowing-agent distribution in the PUR foam. As a result, they are working on a practical and economical procedure to determine the blowing-agent content in the polymer and in foam-cell gas, as well as blowing-agent emissions from the foaming reaction.

Optimizing roofing board

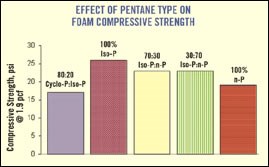

PIR boardstock manufacturers have the opportunity to reduce costs while maintaining or enhancing performance through their selection of pentane blowing agent, according to a study by Huntsman Advanced Technology Center. In their initial conversion from HCFCs, many PIR board makers opted for 80/20 cyclopentane/isopentane blends. Huntsman researchers studied the effect of changing pentane composition on the key performance criteria of PIR board, as defined by the 2001 edition of the ASTM C1289, which puts stricter demands on the minimum compressive strength in the thickness direction and the dimensional stability of the board as compared with the 1998 edition.

A formulation was tested with seven blowing-agent packages: 80/20 cyclo/isopentane; 100% isopentane; 70/30 isopentane/n-pentane; 30/70 isopentane/n-pentane; 100% n-pentane; 64/28/8 isopentane/n-pentane/iso-butane; and 73/19/8 cyclopentane/ isopentane/isobutene.

Results showed that all-isopentane or an isopentane-rich blend with n-pentane has the maximum potential for cost savings while maintaining or enhancing performance (see chart). According to the researchers, cost savings are possible because isopentane and n-pentane cost significantly less than cyclopentane. Moreover, data on compressive strength and dimensional stability suggest that isopentane alone or as the majority component in blends with n-pentane can make boards with lower foam density and lower cost while still meeting structural, insulation, and fire-resistance requirements.

FR spray foams for walls

HFC-245fa is the most logical “clean” blowing agent for interior-wall sprayed insulation, because it requires no costly equipment modifications, unlike pentanes or gaseous HFC-134a. However, 245fa poses three key challenges to formulators that were not an issue with HCFC-141b. First, its low boiling point (less than 60 F) causes problems with material handling and vapor pressure in drums. Second, its lack of chlorine and higher hydrocarbon content diminish its fire-resistive properties relative to HCFC-141b, making it difficult to achieve a Class I rating at 4 in. thickness. The third disadvantage is its higher cost.

Responding to this tradeoff, researchers from Oxid L.P. told how high-functionality polyol mixtures can be used to fine-tune HFC-245fa PUR spray formulations to achieve dimensionally stable, Class I fire-rated foam for wall insulation. In a series of studies, Oxid limited HFC-245fa loading to 8-9% of the total resin blend (vs. the usual 12-15%), with the remainder of the blowing agent replaced by water. While this solved the vapor-pressure issue, it compromised dimensional stability due to the generation of large amounts of CO2 from the isocyanate/water reaction. By using newly developed polyester polyols with higher functionality that allow for greater polyester loading in the overall polyol mixture, researchers were able to reduce the water content.

Oxid’s new Terol 256 and 925 polyester polyols allowed production of dimensionally stable foams with Class I rating at 4.0 in. The lowest smoke obscuration numbers were achieved when polyester level was above 42% and water was below 2% of the resin. Researchers see even more promise with Terol 925 due to its higher functionality, which could allow for loading levels as high as 45%.

New appliance surfactants

New silicone surfactants from GE Silicones reportedly can improve pour-in-place rigid foams for refrigerators and water heaters that are blown with zero-ODP blowing agents. For example, new Niax L-6952 was shown to maximize both flow and insulating properties in HFC-245fa foams.

GE researchers also addressed pentane-blown foams because pentane has been gaining in popularity—particularly in Europe—due to its low cost and lower global-warming potential than HFC-245fa. New Niax L-6885 was found to be the best performer in cyclopentane blown foams for improving flow, insulation properties, and solubility—a frequent problem with pentanes. And because foamers are now investigating isopentane and n-pentane, both of which have poorer resin compatibility than cyclopentane, GE developed Niax L-6889, which provides higher pentane solubility.

Upgraded laminator

Bayer’s Hennecke Machinery Group reported on the latest improvements to its boardstock laminator that has been widely used for nearly 10 years in North America. It now features two AC motors instead of one to drive the two conveyor belts. This change reduces the number of mechanical components like couplings and gearboxes and thereby cuts down on maintenance, according to Hennecke.

To combat the typical accumulation of small bits of foam that break off the edges of the boards during production and become compacted under the laminator belts, Hennecke added new cleanout doors on both sides along the bottom edges of the machine. The doors can be retrofitted in the field to existing laminators.

Hennecke also has a new hydraulic mixhead that boasts minimal operator maintenance compared with the standard spring-loaded head or pneumatic types. An operator now can make multiple pours between injector cleanings, with quick and clean pour starts and finishes. The new head recirculates chemicals when it is not pouring.

News in spray skins

The latest in spray-skin PUR equipment and materials that produce products with an elastomer skin and rigid or flexible foam core were presented by BASF, Linden Industries, and Cannon. Their focus was on “soft-skin” automotive applications like consoles, dashboards, instrument panels, and interior door panels, where PUR is an alternative to PVC, TPU, and TPO cover stocks.

New spray-skin equipment from Switzerland’s Isotherm AG (newly offered here by Linden) has been used to make cushions for medical and tractor seating. Linden is now pitching this equipment at auto interiors because it allows spraying of uniform skins as thin as 0.3 to 0.4 mm with a throughput as low as 10 g/sec.

The newest aspect of spray-skin technology is the substitution of high-pressure metering equipment—Isotherm’s PSM 90 and PSM 3000—for low-pressure mixing. Self-cleaning high-pressure mixheads enhance productivity by eliminating solvent flushing after every pour.

Cannon’s new spray-skin system sprays a PUR elastomer into heated open molds to give a leather-like look and feel to the finished part. The machine has a compact single-frame design, pressurized day tanks, radial piston pumps with magnetic couplings, closed-loop controls with volumetric flowmeters and frequency drives, low- and high-pressure chemical filters, and flow-rate display.

Cannon’s hydraulic mixhead is a self-cleaning high-pressure type. Attached to the head are a wand, spray tip, and a flushing block for solvent cleaning of the wand and tip. The wand permits spraying into deep undercuts on instrument panels.

Also new from Cannon is an additional injection system that allows introduction of multiple pigment streams at the mixhead on demand. It provides virtually instantaneous injection of the third component. An operator can spray one skin color on a mold and then apply a different colored skin on the very next mold. Cannon achieves this by instantaneously reducing the flow rate of the polyol or isocyanate when colorant is required and restoring that component’s flow rate to normal when color demand stops.

BASF reported on its Elastoskin aromatic PUR elastomer, a 100%-solids, two-component system that is mixed immediately before the spray nozzle, whereupon it immediately begins to react. When it is sprayed onto a hot tool, demolding is possible in under 60 sec. Elastoskin boasts high tensile strength at low hardness and consistent feel at low temperature. It has been used in instrument and door panels of Buick, Oldsmobile, and Cadillac models, and in many cases costs less than PVC or other skin materials.

‘Non-emissive’ additives

Suppliers of PUR additives have been challenged to come up with low-emission or no-emission additives for automotive and other industrial applications. Air Products and Chemicals reported on non-fugitive catalysts and surfactants for high-resilience molded foams in auto seating and other uses. New Dabco NE 1070 and NE 300 catalysts are alternatives to commonly used tertiary amines, many of which can volatize under certain conditions. Air Products functionalized the catalysts to react with isocyanate and attach covalently to the polymer network. This renders the catalyst non-fugitive in the finished product. Air Products also reduced the odor and volatility of the catalyst through higher molecular weight and polarity.

Performance of these catalysts was further enhanced by a novel, non-fugitive silicone surfactant, Dabco DC 6070. HR-foams containing these two products reportedly show significant reductions in overall emissions. However, researchers found that humid-aged physical properties of TDI foams made with the new catalysts were marginal in meeting OEM specifications. This led to the development of XF-U13015, an additive that reportedly brings heat-aged and humid-aged properties back into specification and also significantly improves tear strength and compression set. The new additive will be commercial soon.

Modular appliance tooling

A modular tooling innovation for refrigerators and freezers reportedly has decreased costs in commercial production and helped the appliance OEM to launch new products much faster. Hennecke says its concept starts with a base frame and a “core” to which modular components are added to build up a range of appliance models and sizes. The core, normally representing the smallest refrigerator in a model line, consists of three parts—the compressor support, the fresh-food compartment, and the freezer compartment. The compressor support is equipped with a width-adjusting device so that it can be used for all sizes in that line. Mounted on the bottom of the foaming fixture, the width adjustment can be actuated by means of pneumatic cylinders.

According to Hennecke, this is a tremendous feat since the OEM does not need entirely separate tooling dedicated to each model. The savings can be 10% to 30% per modular package—i.e., one core to produce two appliance models—and even higher for one core to make four models.

Related Content

GEON Performance Solutions Buys PolymaxTPE

Combined company aims to be global leader in thermoplastic elastomers.

Read MoreMulti-Purpose TPV with Post-Industrial Recycled Content

Teknor Apex’s new Sarlink R2 3180B TPV offered with 25% PIR content.

Read MoreBiobased TPU for Broad Range of Applications

BASF’s Elastollan N contains 50% renewable raw material.

Read MoreTracing the History of Polymeric Materials -- Part 30: Polyurethane

In the world of polymers, polyurethane chemistry is probably the most versatile. This a resulted in a wide range of products made from these materials and given the industry the flexibility to respond to the progressive march of regulatory concerns.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More