Tags To Climb...Maybe Twice

Despite weak prices in all major-volume thermoplastics, producers of PE, PP, and PS, are hoping to move tabs up once or even twice more before the end of the year.

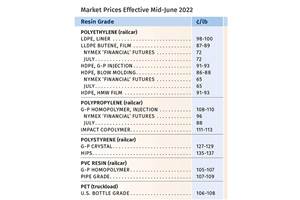

Despite weak prices in all major-volume thermoplastics, producers of PE, PP, and PS, are hoping to move tabs up once or even twice more before the end of the year. PVC suppliers are hoping prices have hit bottom for now. Engineering resins are a different story, with tight supplies helping producers get double-digit increases.

Hikes defy PE softness

Polyethylene prices are going down, but suppliers are still attempting to squeeze out two successive increases before the year is out. PE market prices fell 1¢/lb in September, after a 3¢ dip in August. That leaves PE tabs 3-5¢ lower than at the start of the year, with film grades generally taking the biggest hit. Still, two 3¢/lb price hikes are pending. The first was nominally effective in September, which means Oct. 1 and Nov. 1 for customers with contract protection. The second 3¢/lb increase, nominally for Nov. 1, probably won’t have any real impact before December. It is backed by all major suppliers.

Meanwhile, DuPont Packaging & Industrial Polymers will raise prices of ethylene copolymers and polyolefins by an average of 8¢/lb on Nov. 1. They include Bynel adhesive resins, Elvaloy and Fusabond resin modifiers, Elvax EVAs, Nucrel acid copolymers, and Surlyn ionomers.

Contributing factors: Processors are working off inventories as the end of the year approaches, but softer resin prices derive mainly from new PE capacity that has unbalanced supply and demand. Resin capacity utilization is expected to drop next year to an average level of 83% to 85%.

On the other hand, rising feedstock costs are pushing ethylene prices up. Ethylene contracts held at 30.5¢/lb in September, but were set to rise 1 to 2¢ in October. Suppliers foresee no weakening of ethylene prices in the near future, and further increases in tandem with energy costs are possible.

PP price hike emerges

Polypropylene resin tabs had stabilized through most of October, following a dip of 1 to 2¢/lb in September. But all major suppliers announced hikes of 2 to 3¢/lb for Nov. 1.

Contributing factors: Propylene monomer prices are held to be the main culprit. A 2¢/lb monomer increase was pending in October. Demand growth remains a solid 5 to 6%, but not the double-digit pace of last year. New PP capacity will weigh heavily on prices over the next year. Dow, for example, will bring on 550 million lb by the end of 2000.

PVC continues to slide

PVC resin producers say prices slipped in October and would end the month down 1-1.5¢/lb. Suppliers and processors say prices in the September-October period fell 2.5-3¢.

Contributing factors: At least one resin firm circulated “price stabilization” letters telling processors not to expect further declines while feedstock prices remain high. On the other hand, PVC supply is going up. Shintech will start up a 550-million-lb/yr plant in Addis, La., in December and will ramp up to full production in the first quarter of 2001. Meanwhile, pipe and siding producers say orders have picked up slightly, but are still way below the levels of last spring.

PS makers want 2-5¢ more

Nova, Dow, and BASF announced 5¢/lb polystyrene increases for Nov. 1. Atofina undercut them with a 2¢/lb increase for the same date. But Chevron Phillips had made no move by mid October, putting both the size and the timing of any price hike in doubt.

Contributing factors: If Nova’s third-quarter results are any indication, integrated PS producers are making money on styrene monomer, but not on polymer. Demand was slow from June through October according to both resin suppliers and processors.

Nylon, acetal, PBT, PET

Another industry-wide push is on to raise prices of engineering thermoplastics. Most sources say tight supply is as much to blame for the increases as are rising feedstock costs.

Dow’s 12¢/lb increase on nylon 66 and 6/66 copolymer took effect Oct. 15. Ticona’s 12¢ increase on nylon 66 followed Oct. 16. DuPont implemented a 12¢ increase Nov. 1, while Rhodia Engineering Plastics raised its prices 8¢/lb on the same date. BASF posted a 12¢ nylon hike for Nov. 15.

DuPont and Ticona also want 8¢ more for acetal, PET, and PBT on Nov. 1. Ticona will jump Vectra LCP prices an average of 50¢/lb, and Celstran long-fiber compounds will go up 4 to 6¢/lb.

Related Content

Volume Resin Prices Move in Different Directions

PE, PP, PVC, and ABS prices slump, while PS, PET, PC, and nylons 6 and 66 prices rise.

Read MoreWhat's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.

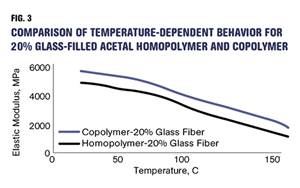

Read MoreHow Do You Like Your Acetal: Homopolymer or Copolymer?

Acetal materials have been a commercial option for more than 50 years.

Read MoreMelt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More