Putting the ‘Flexible’ in Flexible Film Processing

This blown film processor is no stranger to change when it comes to finding new markets with novel products. Its latest: barrier films.

P&O Packaging is quite familiar with capitalizing on new business opportunities. This Dalton, Ga., blown film processor, part of Inteplast Group’s Industrial Films business, started in 1978 making large rolls to package wall-to-wall carpet. In a neighborhood recognized as the “carpet manufacturing capital of the world,” that was a pretty good business to be in at the time.

But times change, and P&O changed with them. Its core market began to shift, beginning with the recession of 2008. The housing bubble collapsed, and carpet manufacturing began to wobble as a result. But rather than wring its hands, P&O initiated a complete realignment of its product portfolio. Over the years it expanded into other niches of the industrial film market and delved into food and specialty film packaging. Then last year, it added capacity to produce highly complex barrier films.

“In 2009, we adopted a strategy to deliver superior value to customers by providing packaging films and solutions that meet or exceed expectations for responsiveness, innovation, quality, and reliability,” recalls Dale Brockman, P&O president. “Because of our strategy, we wound up being the go-to people for certain custom products. That in turn, increased our capabilities and knowledge base.”

As one example of this metamorphosis, P&O introduced a high-tensile-strength sealant web that reduced film thickness by 33%, resulting in a high degree of source reduction while maintaining strength and key product attributes of heavier films. “As a result of this success, several of our food sealant-web customers requested that we broaden our product portfolio,” Brockman says. “They wanted us to add the capability to deliver more sophisticated barrier films. This was the impetus driving a new era at P&O as we moved into the complex barrier-film business.”

P&O has 70 employees at its 60,000 ft ² plant in Dalton and since 2012 has been part of Inteplast Group , a Livingston, N.J.-based integrated plastics manufacturer that produces a wide range of films through its AmTopp and other divisions. P&O’s business has grown significantly since the acquisition, fueled by Inteplast’s broad production portfolio, technical muscle and manufacturing expertise, and its commitment to total quality management.

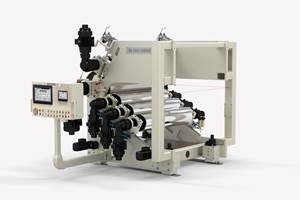

The new nine-layer barrier film line was purchased by P&O from Brampton Engineering, Brampton, Ont. Brockman says the line was commissioned in under 24 hr and was making commercial film after generating less than 2000 lb of startup scrap. The line paved the way for P&O to make further inroads into markets that require barriers to high moisture, oxygen, light, and chemicals, Brockman says. “The line has tremendous flexibility and offers outstanding control of the process,” he adds. “It will allow P&O to be very competitive in providing formable webs and lid stocks for a wide variety of horizontal form/fill/seal applications, as well as vertical form/fill/seal applications for food packaging and moisture and chemical protection for industrial customers.

“P&O will also be capable of expanding into additional niches of the specialty film markets and broadening our product offerings to existing customers,” Brockman notes. “We believe U.S. demand for specialty films will increase in line with market studies that project it to grow 5.2% a year to $8 billion in 2017.”

Brockman adds, “We are excited to participate in the growth of nylon films for meats, cheese, dry foods, industrial applications, and medical applications, and to bring to these markets our ability to produce thinner but higher-performing coextruded films to further reduce packaging costs.”

Related Content

Green’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

Read MoreNew Blown-Film Cooling Technologies Set to Debut at NPE2024

Cooling specialist Addex to roll out new auto-profiling air ring for rotating dies, and new single-plenum air ring.

Read MoreFiltration System Helps Film Processor Manage Recycled Material Mandates

Global film processor RKW teams with Nordson to enable it to process blown film with high recycled content.

Read MoreHow to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

.png;maxWidth=970;quality=90)