Savvy Processors Reveal Best Practices on Drying

The processors speak: Here’s how some smart molders and extruders tackle the vexing problem of resin drying.

No one would dry resin if they didn’t have to. Unlike blending, for example, where novel material combinations can boost part properties, resin drying doesn’t add value to the process. But make no mistake: For processors running hygroscopic materials, getting this necessary evil right is the difference between making money or scrap.

Talk to 10 processors about “best practices” in drying, and brace yourself for 15 different answers. Despite its lofty position in the processing hierarchy of things that must be done right or else, drying is rife with anecdotes about fundamental flubs and oversights—even from seasoned molders.

The drying problem is not a question of adequate technology; indeed, resin-dryer technology has advanced on a regular basis for years. Says one Midwest molder, who spoke on condition of anonymity, “You can have the best dryers money can buy and still be bad at drying.” The issue seems to involve an unwillingness of some processors to take the time required to understand the drying process—not just the intricacies, but the fundamentals.

One veteran processor who has been involved in several turnaround projects at various molding companies put it like this: “Drying is the most misunderstood and poorly applied process facing the industry today. I’m talking about fundamental things done consistently wrong.”

This particular molder, who also asked to remain anonymous. recalls a humbling experience of his own. “I was working with a dryer that was operating just fine for a long time; then out of nowhere, it wasn’t drying at all. We checked the beds, the filters, the connections, everything you could imagine. Nothing helped. So we called the supplier, and they sent a technician in the next day. He checked the same things we did. Then he asked for a ladder. He thought maybe the lid wasn’t assembled properly. He climbed up and found the lid wasn’t even on the drying hopper. Someone had removed it for cleaning and never put it back.”

Making matters worse, as a result of downsizing caused by the economic downturn, some processors—smaller ones especially—have streamlined, if not eliminated, their manufacturing maintenance staffs. In some cases, they’ve shifted that responsibility to engineering. But engineers generally have other things to do beyond tending to dryers, so matters like checking filters, air flow, and desiccant beds get put off. And off.

Jeff Blake is manufacturing engineering manager for Parker Hannifin Corp. in Ravenna, Ohio, which extrudes hose and tubing for a wide variety of end markets, running nylons and TPUs, among other materials. He assesses the situation thusly: “Mom-and-pop molders tend to be concerned about making money on the parts they produce. That’s understandable; but generally speaking, they don’t spend a whole lot of time learning how a dryer works and how it must be maintained. Their mindset is, ‘Here is my material, here is my mold, let me make a part for my customer and make money.’ As a result, they won’t think about changing a filter until the machine stops working.”

The purpose of this article is not to compare various dryer technologies—multi-tower desiccants, wheels, vacuum, etc.—and suggest what might be best suited for your operation. Many of the bigger processing operations use combinations of multiple technologies. There are more desiccant-bed dryers in the field than any other type, but most processors agree that more wheel or carousel-style units have been purchased over the last five or six years. Vacuum units are currently available from only two suppliers: Maguire Inc., Aston., Pa., and sister company Novatec Inc., Baltimore.

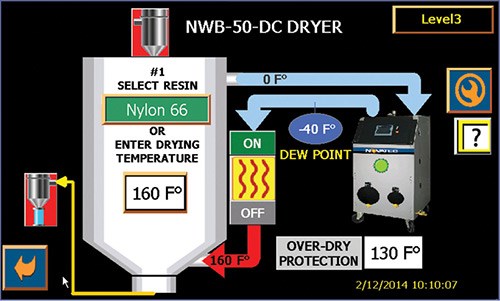

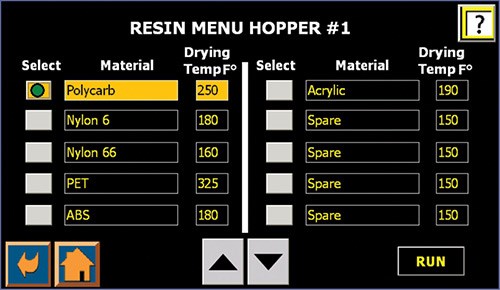

“We use both twin-bed desiccants and new wheels, based mostly on age,” states John Patterson, divisional electrical engineer for injection molding plants at Delphi Packard, Vienna, Ohio. “We currently have dual- bed desiccant towers for our bulk dryers and we also use dual-bed units on the portable dryers. But recently we purchased a bulk wheel desiccant dryer (Novatec’s NovaWheel NW 800) that sends desiccated air to four drying hoppers in one of our Mexican facilities.

“I like the new wheel dryer—it uses far less electricity and is very consistent from a dewpoint standpoint,” Patterson elaborates. “However, our Mexico plant is up in the mountains about 4000 ft and the climate is dry and fairly consistent all year long. So I am really not testing or pushing the capability of the wheel dryer. I would like to have one in my plant in Vienna to see if it really works as advertised.”

These remarks aside, this article is designed to offer some insights on how leading processors handle the big issues related to drying on a day-to-day basis.

ISSUE ONE: CENTRAL VS. FLOOR MOUNTED

Deciding whether to dry material at a central location and convey it to one or multiple machines, or dry it press-side, is one processors deal with almost every time they need a new system. Their decision is sometimes motivated by company culture. If, for example, floor-mounted drying happens to be a particular molder’s “thing,” that’s tough to change.

One molder, who molds 176 different types of materials, including a wide variety of ABS grades and acetal blends, relies strictly on floor-mounted dryers furnished by Dri-Air Industries, East Windsor, Conn. He looks at the question pragmatically: “If I were buying a system to run 100,000 lb/week, I would centralize.”

In some cases, the trend toward molding cells has influenced the decision to “stay local” on drying. Says Jerry Suchanek, tooling engineer for SSI Technologies, Janesville, Wis., which molds sensors for automotive and non-automotive applications using nylons, TPU’s, acetal and other materials, “We currently use only floor mounted. We had considered going to a central drying system but because the molding in a lot of cases is within the manufacturing cell it wasn’t as feasible.” SSI currently has five E60- 50/50/50 dryers from Wittmann Battenfeld, Torrington, Conn. The system combines the Drymax ES60 dryer will three hopper carts for quick color and material changes.

Kevin Skovira, manufacturing engineer at TE Connectivity (TE), Harrisburg, Pa., sees things similarly. This plant molds tiny interconnectors for appliances out of nylon, PBT, and LCP. He says, “We do at-the-press drying because we have molding cells. We’re always changing things and find these systems to be the most adaptable.” TE uses a portable system from Dri-Air called On-Demand Dry, Blend and Convey, in which virgin resin, regrind and colorant are processed on one system.

The decision to go central or floor-mounted is not always an either-or proposition. Some molders do both. Sometimes the choice is based on where the central drying system is located. To hedge their bets, savvy processors who dry centrally may also use a portable or even a throat-mounted drying hopper to guard against the possibility that resin may have picked up moisture during the conveying process.

Sometimes the decision to do both is material-specific. B&B Molders LLC, Mishawaka, Ind., recently installed a new Resin Works drying and conveying system from The Conair Group, Cranberry Township, Pa. The system consists of three wheel-style dryers and 30 individually controlled Resin Works hopper stations, a handful of them dedicated to specific materials, and is designed to deliver high-volume resins to multiple machines.

“The central drying system is more flexible than the one it replaced, and we did have some discussion during the evaluation processes around central vs. floor-mounted drying,” remarks Jim Krezel, B&B’s manager of operations. B&B is a custom molder that runs ABS, PC, various nylons, SAN, and acetals for a wide range of industries. Notes Krezel, “Certainly, the central system eliminated what we did on the floor. However, when we are running clear materials for products that need to be light-reflective, we still dry on the floor.”

B&B typically does as many as four to six mold changes per shift, and its decision to go central is a counterpoint to those who say floor-mounted systems are more conducive to molders who switch jobs a lot. “We pre-schedule everything,” says Krezel. “We’ll start the drying process three to four hours in advance of a job change, so when the new mold is in place, the material is ready as well.”

Krezel adds, “The new system that we installed solved all of the problems that we fought in the past. Having properly dried material when we need it has been fixed. Having capacity to properly dry has been fixed. Handling our regrind has improved dramatically, and today we utilize 100% regrind on products that can use it. Transferring material from material storage to molding and back is now extremely effective and seamless.”

Delphi is another molder that combines central and floor-mounted drying. Delphi runs many different nylons, LCP, PPA, and other materials at its 47 molding plants. Its primary business is automotive connectors, but it also makes parts for tractors, cell phones, and other applications.

States Patterson, “We have what we call high-volume materials that are located in regional drying areas,” he says, explaining his setup. “There are two regional areas in our facility that feed 60 machines each, and each regional area has 16 drying hoppers of various sizes ranging from 1200 lb to 400 lb, and these are controlled by a plenum bulk drying system.

“The bulk drying system is composed of dual- desiccant-bed towers that supply eight of the bulk drying hoppers with dry air. Each drying hopper also has its own process heater and blower motor. Each hopper is individually temperature controlled and we also monitor the dewpoint for each individual drying hopper, which is fed back to the main controller mounted on the bulk dryer.

“Each individual hopper also has (Novatec’s) Moisture Manager control, which means we can block the dry air coming from the bulk plenum and just recirculate the air within the bulk drying hoppers. This way we can control the dewpoint and not over-dry the material. The bulk dryers can be switched based on time or dewpoint. So the eight hoppers are controlled by one bulk dryer, plus there is another bulk dryer wired as a backup dryer.

“The backup bulk dryer is wired such that we can instantly switch over to the backup if maintenance is needed on the bulk dryer that is currently online with the hoppers. The backup dryer is running and ready to go, because we wrote a program that keeps the beds regenerated offline and ready to go online at a moment’s notice.

“Again, there are 16 drying hoppers in each region, so there are four individual tower bulk dryers. One bulk dryer provides desiccated air for eight hoppers, so two bulk dryers are on line at all times, and then there is a backup tower bulk dryer for each set of eight drying hoppers. So each region has four bulk dryers to handle the 16 drying hoppers.”

Patterson adds that Delphi also uses what it calls low-volume (portable) dryers for low-volume materials. “The material is usually in a portable dryer somewhere next to a molding machine if it is not being actually used for a low-volume application. The portable dryer is actually on and running so the material in the dryer is dried. We have controls on the portable dryer to maintain a certain dewpoint level so we try not to over-dry the material, and when the material is needed it is already dry and ready to use. Once attached to a machine, the central vacuum system will pull material from the portable dryer to the shot loader on the machine.”

All the portable dryers—and the low-volume vessels that feed them at the press—are barcoded. “Upon downloading a new tool to the press, it will tell the mold setter that the material is bulk or low-volume,” Patterson explains. “So the system knows what material is supposed to be utilized. Before starting the press, the operator must scan the bardcode on the tool, reject bin, grinder, molding machine, and dryer.”

He continues: “The portable dryer information is stored in a database that says what material currently is in the dryer. If the material was to change in the portable dryer, it must go through a cleanout and be re-scanned at a cleanout station that tells the database the identity of this dryer and gives it a status of ‘cleaned out,’ so no material is designated for that portable dryer. Then, when the portable dryer is loaded again, the dryer is scanned with whatever material is put in that dryer at that time and the database is populated with that information. All the material types are also barcoded. So we know exactly what material is in what dryer at all times.”

The portable dryers are loaded from low-volume vessels, which are 400-lb bins on rollers that are moved out to the molding press next to the portable dryer, Patterson explains. The portable dryer replenishes itself automatically based on level sensors on the hopper of the portable dryer. When the vessel is empty the signal is sent to the press and an alarm is noted on the machine’s control screen telling the operator that the vessel needs to be replaced.

ISSUE TWO: DRYER SPECS & SIZING

Americans tend to like things bigger, and not just SUVs and hamburgers, but dryers too. Yet the feeling among processors is unanimous: Bigger isn’t better in drying, and if you want to oversize to give yourself some flexibility for some future business expansion, do so modestly.

“We started an energy-efficiency program six years ago,” recalls a Midwest molder and extruder who asked not to be named. “We benchmarked our drying against a customer who also happened to be a molder. We found that we weren’t making the connection between the

capacity of our machines and the size of our dryers. Our dryers were too big. We were we over-drying the material and affecting part quality, and wasting energy. We found that 20% of our power was used by our drying process. In some jobs we were processing 4 lb/hr in a dryer with a capacity of 100 lb/hr.”

This firm switched over to Dri-Air’s Arid-X 10 Mini dryers and reports a 20% energy savings in kWh/press-hr even while its business was expanding.

At Delphi, Patterson’s solution is to convey material to the presses using the dry air from the bulk dryers, and then send the material to small-shot loaders so the material does not spend a lot of time at the press and have a chance to gather moisture from the atmosphere.

He adds, “Our plant is also temperature and humidity controlled so we don’t have excessive moisture in the plant.” Patterson notes, “We have two different size portable dryers in our plant. One is for 50 lb/hr throughput, and the other for 25 lb/hr. The size of the part and cycle time dictates which dryer is used in the low-volume case.”

On the overall subject of dryer specifying, Patterson offers, “We generate our own set of specifications for portable and central dryers. We look at residence time and CFM of the dryers. We write our own program for the dryer so we basically can try different things and change the software to do what we want. We try to maintain at least 4 hr of residence time in the drying hopper as a rule of thumb. We tried different dryers in the past when we had a plastic lab. Vendors would give us a dryer and we did testing in our plant. We have offline moisture-testing units from Arizona Instruments and we would measure the moisture content of the material output based on putting in different levels of materials with different moisture levels.”

States Blake “During the specification process, we look at pounds per hour required and the drying time and temperature for the application. I’d have to say throughput rate is typically the most important.”

Adds another processor, “A great many molders miss the beat on matching dryer size to the shot size of the parts they are running. Whether you’re running 3-4 lb or 25 lb or 1000 lb, you’ve got to size the dryer properly.” This molder uses Dri-Air HPD portable dryers and also has larger floor-mounted dryers, model HP4-X 400, with 1500-lb drying hoppers.

Oversizing can also cause problems during molding. One global molder of medical and other technical parts from nylon, PC, acetal, and PEEK makes extensive use of cavity-pressure sensors. It found that material sitting in an oversized dryer would resorb moisture. The result was that all the cavities were not filling consistently. “Our strategy is to size to the press for the type of work we do: high-cavitation, small parts.” This molder has 132 floor-mounted dryers, most of them from Dri-Air, located below its presses. Dried resin is conveyed to molding machines with dry air. A purge valve located below the drying hopper keeps resin dry in the hopper and keeps the material line clear.

Delphi’s Patterson adds, “We use shot loaders on every machine. The shot loaders are fairly small, and we feed the material to the shot loaders with dry air.” Suchanek has a similar approach: “We use extremely small hoppers mounted on the feed throat, almost like a single-shot loader, to reduce the amount of time material is exposed outside the dryer. We also try to keep the entire system as air-tight as is reasonable.”

Adds B&B’s Krezel, “On the molding machines, our system uses small hoppers sized for the press and small-shot hoppers that control material feed and flow to the press. It’s a closed-loop vacuum system that utilizes clean, dry air in the conveying lines. This allows our material to remain dry during material transfers to the press, and the small hoppers allow for efficient use before moisture can return.”

“We also look at air-flow capacity when comparing dryers, adds Patterson. “We look at residence time and, which goes back to throughput, and we also ensure the CFM is properly sized for whatever size drying hopper is mounted on the portable dryer or the bulk drying hoppers. The CFM is dependent on the height and diameter of the hopper. We always consult with the dryer companies to ensure we have the properly sized blower mounted on the system.”

Suchanek sums up the matter of dryer specifying: “I have always maintained that if one supplier were that much above the competition, then they would in essence be the only supplier. So for us it comes down initially to price and reputation/service when first deciding on a manufacturer. We have been trying to commonize to simplify, the goal being to only need to train for and maintain one brand.”

Suchanek continues, “We typically size a dryer for a specific application. Based on the available features of the dryers we have specified, the throughput is adjustable so we allow ourselves the ability to buy somewhat larger hoppers where we custom-tune the throughput to the specified job.”

Says Dave Spontik, technical service manager for Lubrizol’s processing operation in Brecksville, Ohio, “We examine temperature capability, air-temperature control at the inlet to the hopper, airflow volume, low dewpoint, data monitoring, hopper design, ease of loading, ease of cleaning, closed-loop material transfer to the machine, and how easy it is to keep it functional.”

ISSUE THREE: TRAINING

Is dryer training pursued by leading processors? The answer appears to be yes, but probably not enough. “Operators are trained to operate the equipment and to understand the drying requirements of the material,” states Spontik of Lubrizol, which processes TPUs into footwear and performance apparel, film and sheet, electrical components, and an array of other products. “We also train on how the dryer is supposed to function and simple troubleshooting of the system.”

Adds Suchanek of SSI, “We train our molding technicians to operate the dryers and to understand and perform what preventive maintenance is associated with it, which I think helps with troubleshooting. We emphasize material changes, making sure the dryers are clean to eliminate dissimilar materials from cross-contaminating. That’s a big issue for us. Since we run multiple materials at one press, we need to ensure that the hoppers and loaders are completely clean of the previous material. It’s not just the hopper but the hoses, loaders, filters, feed throats, and all those areas where pellets could be left behind.”

Delphi handles things differently. “Operators basically answer alarms and don’t touch the dryers,” says Patterson. “They are essentially locked out from changing setpoints. We have engineers on the floor who do startups and take care of machine problems.”

ISSUE FOUR: MAINTENANCE

Skovira says TE has a large group of highly skilled electricians and has both preventative maintenance (PM) and total productive maintenance (TPM) programs. “We regularly look at wear items like desiccants. We check the purge system and the blowers, looking for trapped materials. We have our material handlers handle the filter changes.”

Delphi’s Patterson notes that his company has a separate maintenance group in the plant. “They will fix the dryers when certain alarms occur, like high dewpoint, heater failures, and so on. We also have a PM program for both the bulk dryers and portable dryers.”

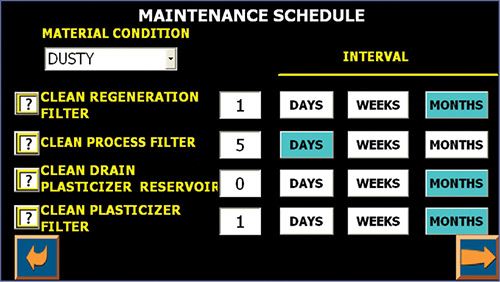

SSI’s maintenance program ultimately gets tied into its ERP program. Says Suchanek, “Initially we follow the dryer manufacturers’ recommendations where maintenance is concerned. We input this information into our ERP system to generate the required work orders, and then add additional PM items as needed if we identify other potential areas of concern.”

One seasoned molder, who happens to be the president of his company, doesn’t always wait for his maintenance staff to check on how things are working. “I’ve always been a hands-on guy and I don’t wait for maintenance to come to me. I’ll walk around the plant periodically. I’ll take my hand and run it around the circumference of the drying hopper, trying to feel for cold spots that might suggest something is preventing the dry air from drying the material uniformly.

“I’ll go out and watch the operators change the desiccants. I’ve seen a lot of operators do this incorrectly,” this molder adds. “They don’t fill the desiccant beads to the top of the tower. When it looks full, what I do is take an object and gently tap on the side of the tower. If you do that, you’ll see the desiccant start to settle, and then you can top it off.”

Blake of Parker Hannifin weighs in: “Our biggest issues are having dryers that run and work consistently, keeping the filters clean, keeping the systems sealed up, and stopping air leakage. We have PMs to verify that the dryers are working consistently. We also have audits by employees who might not be operators to look at the drying systems.”

At Lubrizol, a lot of effort is put into keeping dryers up and running to spec. Notes Roger Clement, technical service engineer at Lubrizol, “We’re drying a variety of materials with different drying conditions that change the throughput rates. We inspect and audit our drying equipment before putting it in use. We use moisture analyzers to check pellet moisture. And we will use multiple dryers and hopper sizes to match the throughput and drying times needed for the specific job.”

Adds Suchanek of SSI Technologies, “After the proper specs are set, the reliability of the overall system and its ability to maintain drying consistency day in and day out are the most important issues for us.”

ISSUE FIVE: HANDLING THE BIG CHALLENGES

The drying issues processors face daily vary quite a bit, but there are a few common threads:

•Regrind: “We move our regrind from our besidethe- press grinder back into material rooms,” says Patterson of Delphi. “In the material rooms we classify the regrind, then ‘family blend’ it with virgin, then send that out to the bulk dryers in the regional system.

“We try to use as much regrind as possible. We have done studies that show we can blend the regrind back in without degrading the material properties up to seven times. We feel the regrind is used up before it is recycled that many times. We blend regrind in different ratios based on how much we generate in the facility.”

Adds Skovira of TE, “We have two main drying hoppers. One draws virgin material from the gaylord. The other is fed ground sprues and runners from a granulator close to the dryer. So we can control the drying parameters of the virgin and regrind separately.”

•Low-temperature drying: Lubrizol’s Clement offers, “Care must be used to avoid material blocking. Recirculation or stirring is sometimes used to prevent blocking of the softer materials.”

•Moisture pick-up in blenders: Recommends Spontik of Lubrizol, “Avoid ambient-air blending if possible and minimize exposure time to ambient- air moisture. Agrees Blake of Parker Hannifin, “Try to limit dwell time in the blender.”

SSI’s Suchanek puts it this way: “We’re only blending HDPE, so moisture isn’t that much of a concern. If we ever had to go that route, my first choice would be to use a compounded material to eliminate the need for blending, otherwise we would need to ensure that we are blending in advance of needing the material so we have time to dry to the manufacturers’ specifications.”

•Separation of blended material in a drying hopper: Advises Clement, “Try to keep the pellet size the same, but this is not always practicable. Side feeders can eliminate this issue but would require another dryer.”

•Air-flow capacity: Says Suchanek, “The larger hoppers we specify lend themselves to cost-effectiveness in regards to volume of drying air. Doubling air flow doesn’t reduce drying time by half, but it doubles operating costs and increases initial capital outlay while typically only returning a 10-20% reduction in drying time.”

•Minimizing residence time: States Patterson, “Material throughput to the molding machines is important. We try to schedule tools in the machines for certain material types so we don’t exceed the drying-hopper residence time. If we happen to be running a lot of one material type, we will put some machines on portable dryers so we don’t overload our bulk system.”

•When to add more capacity: “When our volume throughput exceeds minimum drying residence time, we know we need more capacity,” states Spontik of Lubrizol. “We use moisture analyzers to monitor pellet moisture levels.” Adds Patterson, “We can modify the software and control what material goes where based on what is needed at the time. A high-volume material can become a lower-volume material, so we can change out high-volume materials when needed. We have extra portable dryers ready to go when needed.”

Says Suchanek, “We know we need additional capacity when our changeover times and associated labor costs start to affect production changeovers and our ability to properly maintain the equipment.”

Related Content

Moisture Monitor Provides Instant Readings to Confirm Drying Efficacy

Real-time monitor measures material moisture continually and set points can be configured so that an alert is issued when the specified moisture level drifts outside prescribed limits.

Read MoreConair Names New Execs in Sales, Systems, Product Management and Extrusion

Moves aimed at strengthening customer focus, market awareness, and technical expertise in key areas of our business.

Read MoreResin Drying Hoppers Offer More Energy Efficiency, Durability and Cleanability

NPE2024: Drying hoppers provide improved energy efficiency and a durable textured metal exterior finish. Thicker insulation provides a cooler working environment, while polished stainless steel interiors resist material entrapment, and make cleanouts and changeovers faster.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More