Extruder Degassing: Is a Central System Right for You?

Centralization vacuum pumps have been used for many decades, most widely used in packaging. For extruder degassing the technology can be useful when several production lines are operated in parallel

Our daily life is characterized by information and supplies from central sources. Messages are collected locally, processed centrally and distributed. In many cases, our electricity, water, gas and telecommunications networks are centralized, as are our wastewater disposal systems. Individual networks can be structured regionally or nationally. In each case, several users in a network are combined on one supply unit.

In vacuum technology, the centralization of vacuum pumps has been used for many decades. Vacuum systems are most widely used in packaging application. The advantages are obvious:

- Vacuum pumps are combined in a cooled location that is soundproof and where the waste heat from the vacuum pumps can be easily harnessed.

- The central vacuum system can be easily adapted to the required pumping speed. The pumping line network buffers short-term air infiltration, creating low pressure peaks.

- The pumping speed control unit delivers the pumping speed actually required. Design uncertainties leading to unnecessarily large systems, concerns about operating safety, or jumps in the size of vacuum pumps are all no longer applicable.

Centralized systems are used in many processes and applications, such as in hospitals, printing companies, for pneumatic conveying and compressed air supply systems.

The use of centralized vacuum supplies for extruder degassing can be useful when several production lines are operated in parallel. Extruder degassing is the removal of gas from polymer melt in an extruder to remove volatile substances and thereby ensuring a consistently high product quality. During this procedure, similar processes are combined and supplied by a central vacuum system. In the production of profiles, central vacuum systems are installed to degas the PVC melt; in compounding, they are used to degas the technical polymer melt. Furthermore, a central vacuum supply could also be used for the calibration tanks in profile extrusion.

In addition to demand-driven energy consumption, the main advantage of central vacuum units is the reduction in installation work. The central systems described below are based on air-cooled claw vacuum pumps that do not require any operating fluid.

Separation on the Extruder

A shut-off valve and a pre-separator are assigned to each degassing point. The shut-off valve separates the degassing point for maintenance work, product changeovers or capacity adjustments in production. The pre-separator is installed between the degassing nozzle and the shut-off valve. The separator is designed according to the gas components in the polymer melt. Solid process components are retained in a settling tank. Condensable or crystallizable vapor components are removed from the vapor flow as early as possible via cooled surfaces. The aim of each separation is to protect the subsequent installation and to retain free-flowing substances within the vacuum installation.

Collecting piping

The collecting piping forms the connection between the individual extruders and the vacuum system. The material should not come into contact with the vapors inside and outside the pipe. Deposits will form inside the piping because the vapor components can never be one hundred percent separated. The question to be clarified in each individual case is whether deposits should be prevented by heating or whether the pipes should be replaced at appropriate intervals by larger sizes and favorable materials. Deposits in the pipes increase over time. The additional layer in the pipe provides insulation, meaning that the amount of deposits in the pipe will decrease over time. These gas components must be separated upstream of the vacuum pumps.

Separation Upstream of the Vacuum Pumps

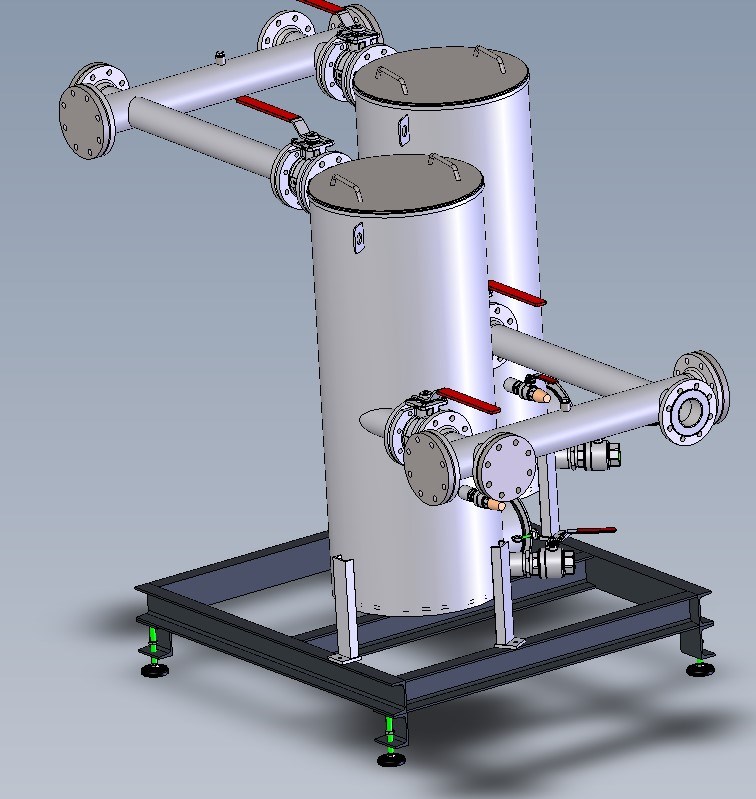

The vacuum pumps must be protected from process components. In the simplest case, the process components are detached deposits from the collecting pipe. If liquids are not specifically drained from the pipe at collection points, the liquids (e.g. condensates) must be retained upstream of the vacuum pumps. A very practical separator is the standing filter (Fig. 1), which protects the vacuum pumps from solid and liquid process impurities. In the central vacuum system, there are two standing filters (Fig. 2) to allow users to switch to the cleaned second standing filter during maintenance.

Central vacuum systems

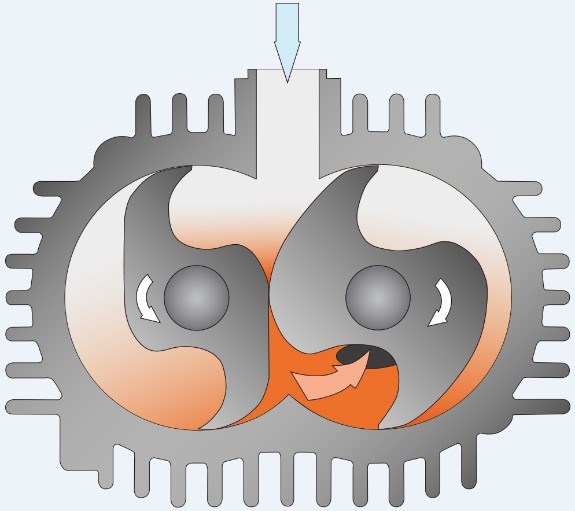

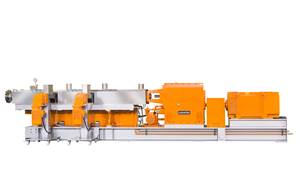

There are no special vacuum pumps for central vacuum systems. In plastic degassing, claw vacuum pumps (Fig. 3; 4) that require no operating fluids and are contact-free have proven themselves.

More than 1000 individual systems with claw vacuum pumps for extruder degassing are in use worldwide. The advantages of using operating-fluid free claw vacuum pumps in central vacuum systems are:

- A claw vacuum pump is air-cooled and does not require a water supply.

- A claw vacuum pump operates contact- and operating fluid-free.

- A claw vacuum pump can be controlled in a wide speed range via a frequency converter.

- The two-stage arrangement of claw vacuum pumps means the operating point can be adjusted in a reproducible manner to save energy.

- The minimized energy consumption in the two-stage operation of claw vacuum pumps reduces the compression temperatures of the process vapors, which are not thermally damaged any further.

- Low compression temperatures increase the life cycle of the vacuum pumps.

- A pump size can be used as a modular vacuum generator so that the machines can be easily exchanged or the vacuum system easily expanded.

- The spatial separation of the central vacuum system and extrusion facilitates the maintenance of the systems, improves the control possibilities of the individual links in the extrusion process chain and increases reliability.

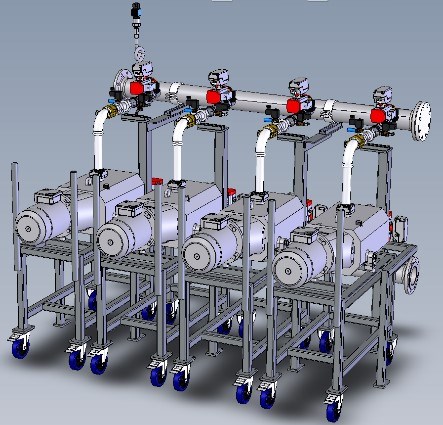

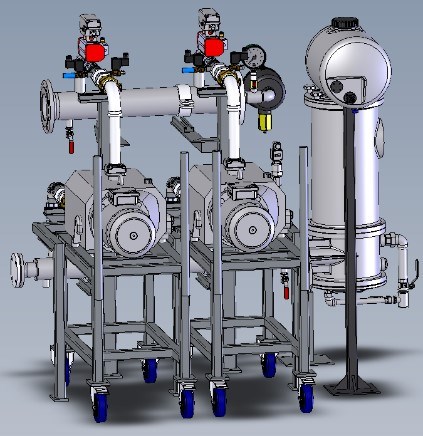

An example of the design of a vacuum system is in Figs 5, 6 and 7.

The individual vacuum modules are designed with identical vacuum pumps, meaning that it is possible to use the vacuum modules as a booster stage or preliminary stage. The vacuum system shown is a two-stage arrangement, which is selected for inlet pressures < 200 mbar each.

The booster stage compresses from the selected inlet pressure to an intermediate pressure which, depending on the process, is 2–5 times the inlet pressure. The preliminary stage compresses from the intermediate pressure to atmospheric pressure. The required pumping speed for the preliminary stage is reduced in line with the compression ratio of the booster stage. The booster stage has a power consumption of 30–50% of the rated output for single-stage compression against atmospheric pressure. The preliminary stage is operated at rated output. Thanks to the low power consumption of the booster stage and the high gas mass flow – which ensures good internal cooling – the gas temperatures after the preliminary stage are 60–100° lower than with comparable single-stage compression.

A central vacuum system with claw vacuum pumps for extruder degassing is an energy-efficient and reliable concept. The air-cooled claw vacuum pumps don't need any operating fluid or a water supply. Maintenance work and monitoring required for the vacuum system is carried out at one location. The required pumping speed can be controlled with reproducible results. The vacuum pumps' process loads are reduced and the vacuum system's service life is increased with little maintenance effort.

ABOUT THE AUTHOR Uli Merkle has more than 30 years of experience in industrial vacuum technology. He is now the head of Marketing services at Busch Dienste GmbH in Germany, part of the international group of Busch Vacuum Pumps and Systems. He has released numerous publications about industrial applications involving vacuum technology. Contact: uli.merkle@busch.de

Related Content

Equipment for Compounding, Reactive Extrusion, Devolatilization, Foaming and Direct Extrusion

NPE2024: Leistritz to focus on advances made via twin-screw extrusion.

Read MoreNew Machines, Spare Parts and Auxiliaries for Compounding

NPE2024: ENTEK displaying a range of products at the May show.

Read MoreUnderstanding 'Boundary Conditions' in Twin-Screw Compounding

In twin-screw compounding, the objective is generally to produce the highest quality product at the maximum strand. But sometimes there are operating parameters that prevent this objective from being realized.

Read MoreThe Importance of Specific Mechanical Energy During Scaleup in Twin-Screw Extrusion

In this case study, the specific mechanical energy obtained on the laboratory scale TSE served as a key parameter and reference for subsequent scaleup activities.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More