Solvent-Based Inks Boost PET Recycling

Sun Chemical’s SunSpectro SolvaWash solvent-based inks allow higher quality and yield of recycled PET from bottles.

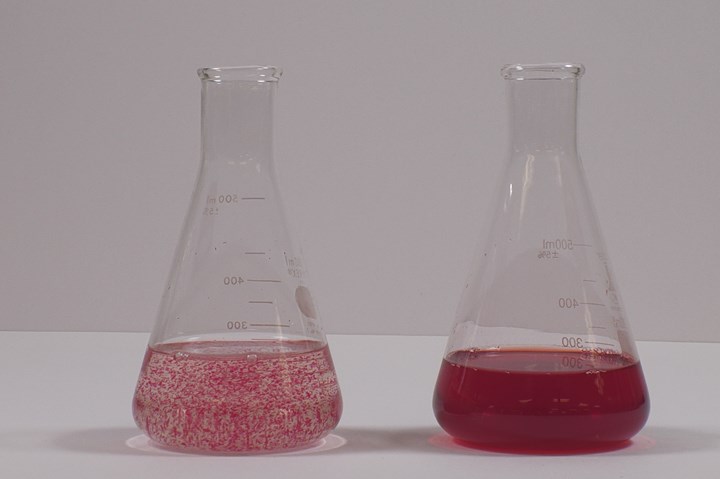

Sun Chemical’s SolvaWash ink product on the left compared with conventional ink on the right. SolvaWash washable ink releases from the film in a controlled process that generates particles large enough to be easily filtered and removed from the wash solution. (Photos: Sun Chemical)

Sun Chemical has launched a recycling-friendly, solvent-based ink that it says will boost recycling rates for PET bottles. Its SunSpectro SolvaWash GR and FL washable/deinkable gravure and flexo-printable inks are designed for reverse printing of crystallizable PET shrink sleeves. The ink has been recognized by the Association of Plastic Recyclers for its ability to be removed without staining the flake or wash water from post-consumer printed PET packaging during the hot caustic wash step of the recycling process.

According to the EPA, the recycling rates for PET bottles is about 29%, in part because removing inks and labels from the PET bottles during the wash cycle is challenging. As Nicola Juhasz, technical director of sustainability for Sun Chemical, explains, problems arise when conventional inks bleed during the caustic-bath washing process, discoloring the solution and contaminating the plastic in it. The contaminated plastic retains some color and can’t be reused in a high-end application, so it’s either landfilled or used in lower-end applications.

How it Works

After being isolated from the bath, the SolvaWash product on the left comes out clean and clear, compared with traditional ink on the right.

SolvaWash is printed directly on the film without the need for a primer. In a caustic bath, the washable ink releases from the film in a controlled process that generates ink particles large enough to be easily filtered and removed from the wash solution without contaminating the recovered plastic.

SolvaWash is the first generation of products that Sun Chemical has designed for PET container sleeves. It is also developing additional product families that are UV curable and/or water-based for the same applications.

Ink technologies are not limited to PET bottles or container streams, so the company is looking to extend it to a variety of additional plastic packaging applications. They’re looking at other streams and ways of using the same concept to enhance recyclability of other types of plastic packaging.

Related Content

-

Sidel Acquires Another Label Machinery Firm

Makro Labelling adds low- to medium-speed technologies.

-

Press-Side TCUs and Full-Plant Adiabatic Coolers

NPE2024: Frigel North America will launch RSY Syncro and RS/MD series, as well as new innovations in at-the-press and whole plant cooling.

-

Eco-Sustainable Pad Printing Ink

Incups GN Series passes the ISO cytoxicity test and complies with EuPIA.

.png;maxWidth=300;quality=90)