Tension-Indicating ‘Smart’ Bolts Make Mold Mounting Safer, More Efficient

No more guessing about whether mold-mounting bolts are tightened properly, with an alternative to unreliable torque measurements.

The bigger the machine, the heavier the mold, and the greater the stripping forces when the clamp opens—all of which add up to ongoing safety concerns for injection molders about secure mounting of molds to machine platens. Some injection molders have addressed this by adding more bolts or clamps to secure their molds and scheduling redundant bolt-tightening checks, which is potentially wasteful and, in some circumstances, can even lead to mold damage.

John Bozzelli, a well known injection molding trainer and consultant (and long-time contributor to this magazine), says, “I have had a number of clients request a seminar on how to mount molds. Clients were tired of having molds drop out of the platens—literally fall out. Can you imagine the cost and safety concerns? evidently, this has become a major issue in our industry, and it needs attention.”

One company that is giving this issue serious attention is Industrial Indicators (aka Stress Indicators Inc.) in Gaithersburg, Md. (industrialindicators.com). Over 20 years ago, the firm developed a “direct tension indicating” (DTI) bolt with an indicator that changes color in response to the degree of “stretch” of the bolt as a result of tension. In the past 12 years, it has refined the technology for injection molding with the help of some beta-test sites doing automotive molding with large presses. “The molding market is growing rapidly now,” says account manager Matthew Hallwig.

Why Not Rely on Torque Wrenches?

According to Industrial Indicators, “There is no clear industry standard on how to properly secure injection molds.” Notes Hallwig, “We have seen incredible variation among molders in the type of bolts and type of tools used to tighten them.” Some molders reportedly have developed complex spreadsheets full of notes to calculate the number of bolts that would be required to secure various molds to platens. Others have struggled to control the torque applied by operators, which is made even more difficult as bolt sizes get larger and the torqueing forces required to tighten them increase exponentially.

Some molders use wrenches that can be set to apply a certain amount of torque (“torque wrenches”) as a standard test of adequate bolt tightening. But Industrial Indicators engineers point out that torque is a rotational force, not a compressive force, and thus is commonly mistaken for a measure of joint security. One reason is the unknown and variable friction factors that can alter the clamping force of bolted joints, even when operators maintain a consistent torque specification. Even more serious is the phenomenon of “bottoming out,” when a bolt is too long for the hole in which it is inserted and reaches the end—or bottoms out—before the head of the bolt can clamp onto a surface. The bolt seems tight, and if checked with a torque wrench there would be no warning of a problem, even though the bolt has no tension is not clamping anything together. This is a dangerously deceptive occurrence, which can be easily overlooked unless tension-indicating bolts are used, according to Industrial Indicators. What’s more, applying too much torque to hardened bolts can damage threads in softer platen steels.

A better answer, according to Industrial Indicators, is its DTI Smartbolt line, which applies strain-gauge technology in a unique way. The head end of each Smartbolt contains a central pin with a chamber containing a pressurized liquid indicator. As the bolt stretches in response to tightening, that relieves pressure on the liquid, which changes color in response. The center of the Smartbolt appears bright red when it is loose, and gradually changes color from shades of brown to black when fully “tight,” according to the preselected Design Tension for the bolt. Design Tension is selectable by the customer, in consultation with Industrial Indicators. According to Hallwig, SmartBolts for injection molds typically have a Design Tension set at 35% to 45% of fastener proof strength, measured in kilopounds, though that figure sometimes has been as high as 60%. A lower Design Tension allows for longer bolt life and reduced platen thread wear, Hallwig notes.

Direct Tension-Indicating (DTI) SmartBolts provide easy visual indication of tightness or looseness in real time.

DTI SmartBolts can be tightened with conventional tools; they have a one-year warranty; and the indicator is certified to function between -4 F (-20 C) to 168 F (75 C). SmartBolts are supplied with a verification sheet that shows the indicator color from 0% to 100% (fully tight) of Design Tension at intervals of 25%. The color indicator is said to be accurate within 10% of Design Tension. The indicator reportedly cannot be damaged by over-tightening, provided that the bolt is not tightened beyond its elastic limit (proof load).

SmartBolts are available in sizes from 5/8 in. up to 2 in. diam. The cost is only about 10-15% more than standard bolts, but Hallwig says the difference is more than compensated by increased safety, resulting in lower risk of worker injuries or damage to expensive molds. SmartBolts also help users improve operational efficiency by potentially reducing time spent on mold changes removing and installing excessive numbers of bolts and confirming bolt tightness with wrenches. Reduced damage to platen threads from over-torqueing bolts is another claimed benefit.

Automotive Penetration

Hallwig estimates that DTI SmartBolts are being used to varying degrees in around 15 injection molding plants, mainly among automotive molders with large machines. In 2018, one automotive molder with 36 big machines (up to 4000 tons) installed on all its presses. The facility averages over a dozen mold changes per day. Prior to installing SmartBolts, the facility had experienced almost weekly mold slips—warning events when bolts loosen enough to allow the mold to slip down the platen though it still hangs in place—and even occasions of a full mold drop. In six months after installation of SmartBolts, the plant reportedly had experience zero mold slips or falls, and on three separate occasions identified SmartBolts that “felt” tight but had bottomed out in the bolted joint. A manufacturing manager at this plant told Industrial Indicators, “I’ve been in this business for 31 years, and the thing I’m most proud of in my career is implementing SmartBolts.”

Verification chart for DTI Smart Bolts shows the gradual change in color from “Loose to “Tight,” graduated in percentages of maximum Design Tension.

Now More Than Ever

Conditions in the plastics industry would seem propitious to the introduction of a product like SmartBolts. As consultant Bozzelli told Plastics Technology, “In my decades of going into shops, I have seen a few molds come loose—not fall, but come close. In more recent years, it has gotten worse and is something I check before I start working on a press. Most processors in the earlier years had some background with tools. We worked on cars or farm equipment, etc. Today, far fewer processors have any mechanical background or experience. So something as simple as tightening a bolt is not done properly. Nobody trains how to do it. It is assumed everybody knows how to use bolts, but they do not. Plus, most shops do not like to buy tools, as they disappear. Torque wrenches are a bit pricey, so they are not often purchased for the workers; and if they are, they do not last long on the shop floor. Sometimes, workers do not even know how to use them properly.”

Industrial Indicators is beta testing new lines of products for injection molders. One is the Chroma series of SmartBolts, which will have color indication for “Loose, Tight, and Over-Tight” conditions. It will also offer digital remote load monitoring and closed-loop tension control. A new line of tools—the company’s first—will convert the sensed load into a digital value. What’s more, in tightening mode, the tool will cut off when it senses the right tension.

Related Content

Air Ring Add-On Brings Output to New Level

The Short Stack from Addex sits between the air ring and die and provides high-velocity air flow to boost output and lock in the bubble.

Read MoreCobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.

Read MoreHow Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

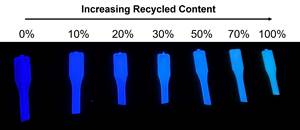

Read MoreFast, Simple QC Method Directly Quantifies Recycled Content in Plastics

Novel fluorescence-based spin-out technology provides a rapid and reliable method to measure and certify recycled content in a wide range of plastics.

Read MoreRead Next

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More