Investments in upfront engineering enable contract-manufacturing partners to transfer the tools, not the challenges. (All Photos: Metro Mold & Design)

For many reasons, manufacturers may find themselves in need of a new supplier that can successfully handle a tool transfer for high-volume, complex parts. They may be looking for a supplier that can provide more consistent results, produce parts at a lower cost, help them move from captive to outsourced production or manage their reshoring program.

At Metro Mold & Design (MMD), Rogers, Minn., we recently managed a challenging tool-transfer program. A prominent HVAC and plumbing parts manufacturer needed a new partner that could overcome its current supplier's struggles to hold very tight tolerances and deliver on-time parts for a range of part numbers. We needed to ramp up to quickly manufacture over 5 million parts annually of several parts that make up the customer's commercial and residential plumbing systems.

The allocation of time and resources to evaluate the program and ensure it would be a good fit is fundamental for success in an initiative of this magnitude. In this project, for example, MMD leveraged its particular competencies by focusing on high-volume, low-mix, highly automated manufacturing programs to realize the greatest ROI for both our customers and our company.

Once we determined that the program was a fit, our program approach began with a holistic tooling analysis. This was quickly followed by an investment in upfront engineering and creating a dedicated production environment that would enable us to deliver consistently the desired outcomes: high-quality parts, on time, at the lowest possible cost.

A three-fold approach to a tool transfer program—holistic tooling analysis, upfront engineering and creating the right manufacturing environment—yields success.

A Holistic Tooling Analysis

With expertise in both tooling and molding, every transfer program at MMD begins with a tool evaluation. A thorough review of each tool from our on-site maintenance engineers, coupled with strategic partnerships with outside tool shops, allows us to immediately identify potential issues, ensure long-lasting tooling performance and uncover opportunities for continuous improvement.

A thorough review of each tool by MMD's on-site maintenance engineers allows for immediate identification of potential short- and long-term issues.

In this case, we knew that the greatest path to success and a long-term partnership would begin with a holistic tooling analysis to uncover tooling challenges that had to be addressed. This process made it possible for us to refine and repair tools and identify steps we could take, including replacing barbs and fittings, to prevent the customer from investing in new tooling. We worked closely with the original tool builder and customer to implement these changes, which helped us to get the tools ready for production as quickly as possible.

Investment in Upfront Engineering

In addition to evaluating the tooling, an investment in upfront engineering is critical to set the customer up for success. The goal is to develop efficient injection molding operations that will deliver high-volume continuous production while avoiding costly delays. Through this process, our two greatest manufacturing obstacles were pinpointed: material performance and large volume.

First, we had to gain a deep understanding of the materials. We were asked to use challenging, high-temperature materials that make holding tight tolerances extremely difficult. Leveraging our materials expertise, our team evaluated critical performance characteristics to avoid part-quality concerns and determine the impact these materials would have on our work cell.

Second, to integrate a large-scale production program into our facility—one that would immediately produce approximately 5 million parts annually— we had to implement an efficient automated packaging system. This streamlined system would allow all parts to be dropped onto a cooling conveyor and then bagged and weighed at the same station.

Through this investment in upfront engineering, we also identified how to maximize injection press utilization. This provided a two-fold benefit: confidence in our ability to produce the program's high volumes with limited interruptions, and radical cost reduction.

Investments in upfront engineering ensure your team is transferring the tools, not the problems. For example, MMD dedicates its engineering, production, manufacturing and operational resources to the customer's program upfront to identify the most successful way to manufacture parts to exceed customer expectations.

Creating the right manufacturing environment is critical to a tool transfer's success, as it meets the program's immediate needs and accommodates future growth.

Customized Work Cell

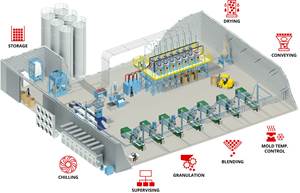

Creating the right manufacturing environment is an equally critical investment in the success of a tool-transfer program. For this program, MMD made a significant investment to replace an outdated automation system previously used for this program and build a dedicated customer work cell in our Rogers facility that would guarantee ongoing performance while facilitating fluctuating volumes.

The fully scalable manufacturing environment incorporated two 250- to 300-ton injection machines equipped with robotics and end-of-arm tooling and the automated packaging system. Shortly after the program's launch, MMD proactively invested in a third press in anticipation of higher volume.

This investment in additional injection molding capacity proved important. When one of the customer's other suppliers ran into a problem, the work was quickly transferred to MMD, and our customer didn't miss any valuable production time.

The work cell was designed to run the machines 24/7, minimizing mold changeovers, press downtime and streamlining operations. This approach limited operator involvement to just one individual for every three machines, significantly reducing labor costs.

Overall, the ability to optimize programs is an essential capability of a strong contract-manufacturing partner and a fundamental step in MMD's tool-transfer program. Holistically evaluating the program's needs will enable you to design and build a customized work cell that meets the tool-transfer program's immediate needs while accommodating future growth and driving longer-term cost reductions.

Combining a wide range of in-house competencies with the discipline to drive the greatest value, the MMD team quickly and efficiently executed the tool-transfer program. The first year saw production of more than 5 million high-quality parts while maintaining an average scrap rate of 0.8%. The program has grown to be one of MMD's largest today.

Team Commitment & Focused Approach Yield Success

We credit the program's success to our commitment to high volume, low-mix, highly automated manufacturing programs, where we know we can produce exceptional value for our customers. This focus is coupled with our three-fold approach to any tool-transfer program's success: holistic tooling analysis, upfront engineering and creating the right manufacturing environment.

MMD's cross-functional team contributed to the success of the tool transfer by identifying and integrating tooling changes, addressing material issues and building the right manufacturing environment.

Perhaps most important in driving our success was the role and commitment of a talented, cross-functional team. Recognizing the criticality of speed and agility, this team identified and integrated tooling changes, addressed material issues and designed and built a manufacturing environment that put the tools into production at MMD without major interruptions in supply.

It was our engineering and teamwork that won us this program and was behind our early success. But it is our bigger commitment to being an integral part of our customer's day-to-day operations and continuously driving greater value that fuels this growing partnership.

ABOUT THE AUTHOR: Ben Lampron is v.p. of Metro Mold & Design of Rogers, Minn., a contract manufacturer in injection molding, blow molding and thermoset molding. He is responsible for day-to-day management of the Consumer & Industrial business, with a particular emphasis on developing and leading strategic growth initiatives. His additional initiatives and responsibilities include managing key supplier relationships, managing the business through an 80/20 philosophy to deliver the best results for customers, aligning employees with customer needs, and growing the business. Contact: 651-280-5941; Ben.Lampron@metromold.com; metromold.com

Related Content

A Cost Saving Modular Approach to Resin Drying Automation

Whether implementing a moisture-sensing closed-loop system for a single dryer, or automating an entire plant, technology is available to take the guesswork and worry out of resin drying. Using a modular approach allows processors to start simple and build more capabilities over time.

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreEnsuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreRead Next

Performance Plastics’ Secrets to Seamless Mold Transfers

Half of this Ohio-based molder’s client base started with a mold transfer. The firm shares the secrets of its success here.

Read MoreEight Steps Toward a Seamless Mold Transfer

It’s big news when an OEM decides to move a substantial number of molds from one processing operation (either their own in-house/captive facility or an outsourced molder) to another.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More

(2).jpg;maxWidth=300;quality=90)