“Why do our clients choose us? Because we teach our people how to manage the various risks in engineering and manufacturing. The result is lower risk for our customers.” That’s David Kachoui’s answer to a fundamental competitive question, and the key word in his answer is manage. For him and for Natech Plastics, a contract manufacturer where he is director of business development, the key strategy is to manage what Kachoui terms “the three main areas of weakness in our industry: product management, project management, and talent pool.” Natech’s solutions are to provide ample engineering support and design analysis up front; to train engineering and production personnel in project management; and to ensure high standards of product quality and plant safety by motivating staff through continuous training, collaboration, and mutual respect.

A CHALLENGING ENVIRONMENT

Based in Ronkonkoma, Long Island, less than 50 miles from New York City, Natech Plastics (natechplastics.com) was founded in 1998 by Gerd Nagler, a German-born toolmaker with a specialty in high-precision, high-cavitation caps and closures, and father of the current CEO, Thomas Nagler. The 15,000 ft2 headquarters houses the administrative and engineering offices and warehouse. There is currently one injection machine there—a 66-ton, all-electric Arburg press installed three years ago for mold qualification and early-stage production of medical parts. However, a 5000 ft2 Class 8 clean room is due for completion this month, with room for up to five more Arburg machines.

Less than a mile away is the firm’s main production plant, with 10,000 ft2 and 13 Nissei and Toshiba presses from 40 to 400 tons. The two plants employ 65 people.

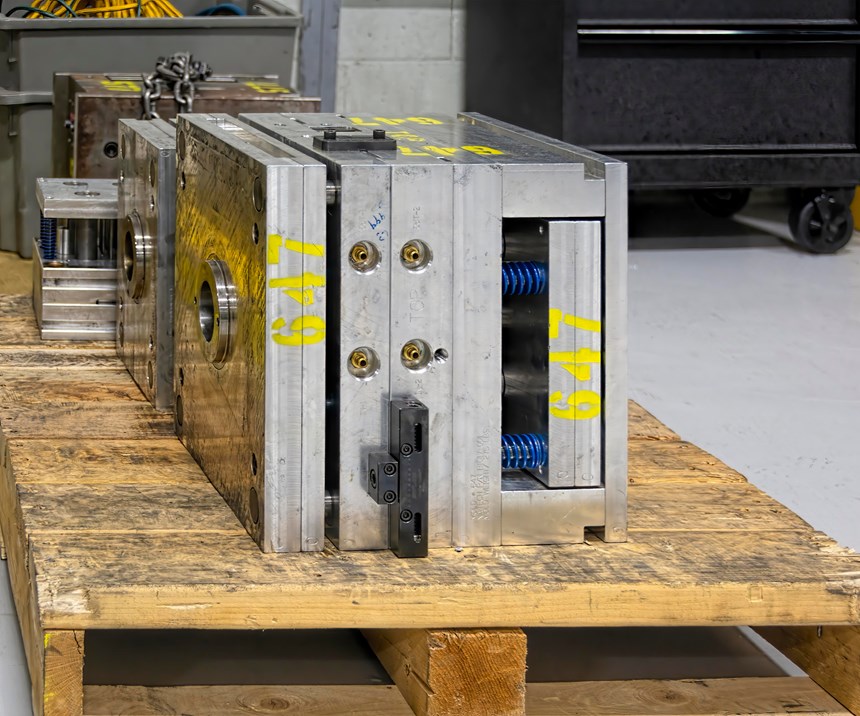

In 2018, Natech purchased a medical moldmaker, Thal Precision Industries in Clark, N.J., and moved the operation and its staff of eight to a new 10,000 ft2 location in the same town. It focuses on high-precision moldmaking and will continue to serve its own customers besides Natech.

The company generates almost $15 million in annual revenue, which has averaged double-digit growth since the company’s founding—despite the relatively high costs for taxes, labor and energy that come with operating in the Greater New York City region. Kachoui says another expansion is under consideration—namely, siting another plant in the Southwest or Midwest to be closer to customers, perhaps in the next two years.

Natech focuses on three main markets. The majority of its business—about 60% now and growing—is in medical parts and assemblies for single-use, metered-dose and multi-use disposables for drug delivery, as well as diagnostic devices. The other two main sectors are packaging and electronics, including battery housings and electronics for medical equipment.

MANAGING RISKS

Managing risks for Natech’s customers is the job of its engineering staff of eight (not counting a mold designer), which will soon be expanded by one, Kachoui says. “Engineering support to customers is a very important advantage for us,” he explains. “We perform a lot of Design for Manufacturing (DFM) analysis on customer’s product designs. We identify and manage the risks to cost, quality, and delivery. Customers value that highly.”

Josh Romero, senior project engineer, also credits rapid prototyping as a risk-reduction tool. Natech acquired an SLA-type Formlabs 3D printer in 2017. “We use it for design iterations, functional checks, and to evaluate tolerance stack-ups on assemblies,” he notes. “We even use it to test snap fits. We can do that because the material available for this machine imitates the properties of a production molding resin.”

According to Seemab Yousuf, senior applications engineer, evaluating those risks has been enhanced by Autodesk MoldFlow analysis of part and tool designs. Until recently, that task was outsourced, but last year, Natech brought that capability in-house. “We used to use MoldFlow relatively rarely, but now we do it every week,” Yousuf says. “It helps us test our assumptions for DFM and correct them, if necessary. MoldFlow analysis is our early warning system for problems like sinks or warp issues. If we want to make a design change to avoid those, and the customer asks why, we now have a way to show them the data. Or, if the customer makes a design change, we can check to see whether it will cause any new problems. Overall, flow analysis makes us more confident to release a design for mold build. And it gives clients more confidence, too.”

Another risk-abatement procedure is mold qualification on the company’s newest press, the 66-ton Arburg. Matt Roane, a process engineer and recent graduate of U. Mass.-Lowell’s plastics degree program, performs these trials using Scientific Molding. He uses Design of Experiments (DOE) to characterize the dimension and control process windows and performs capability studies to determine the Cpk values. The company is now also using an RJG Inc. eDart process monitor for that task.

Says Roane, “Once we qualify a process on this machine, we can transfer it to any other machine.” He explains that, according to the principles of Scientific Molding, each machine’s settings may be different, but so long as the resulting process variables—what the plastic experiences—are the same, the part quality should be predictable. (Natech’s approach to Scientific Molding is detailed on its website, natechplastics.com/injection-molding.)

Sometimes, the part quality cannot be determined immediately after molding. On a recent afternoon, quality-assurance manager Andrew Dunham was conducting a shrink study of an ABS part for an electronics enclosure. The parts were to be held overnight for a final dimensional check.

MANAGING WITH TECHNOLOGY

Natech Plastics sometimes competes with molders in lower-cost manufacturing environments, both in the U.S. and in Asia. Natech has responded with a number of incremental investments in efficiency and productivity. One example has been continuously renewing the firm’s fleet of injection machines. Four of the newer machines are all-electrics, which have proved faster in many applications, according to Galo Lopez, shift foreperson. Several other machines are servohydraulic types, which save almost as much energy as all-electric types.

Since 2014, Natech has been operating those machines according to the principles of Scientific Molding: “It means having control over your process,” says Kachoui. “You establish the process window up front, and if you stay within that window, you get good parts. Process variation is a reality, you can’t avoid it. But Scientific Molding accounts for variation in advance. We’re not so reactive as we used to be.”

Natech has also moved toward increasing automation to boost productivity and free its employees from tedious, repetitive tasks. All its injection machines are equipped with servo-driven linear robots from Arburg or Yushin America. On some jobs, two arms are mounted on the same robot beam—one to deliver the parts to a takeoff conveyor, and the other to deliver the runners to a beside-the-press grinder. One robot has a gate clipper mounted on the beam, so that the end-of-arm tooling makes a stop to trim off the runners, which fall into a granulator, before laying the parts on a conveyor.

Kachoui says the company is also looking into the new breed of collaborative robots (“cobots”) to relieve workers of other repetitive tasks by automating downstream operations like assembly, decorating and packaging. The advantage is that cobots reportedly can operate relatively safely in close proximity to humans.

Natech’s moldmaking operation is gaining experience in working with soft tools. According to Yousuf, demand is growing for aluminum molds, which are faster and less expensive to produce. Natech uses aluminum mainly for “quick-turn” molds with one to four cavities for “proof of concept” in medical and consumer products. He says these aluminum molds are guaranteed for 10,000 shots, but he has seen them run for over 100,000 cycles—“It depends on the geometries and material being run.”

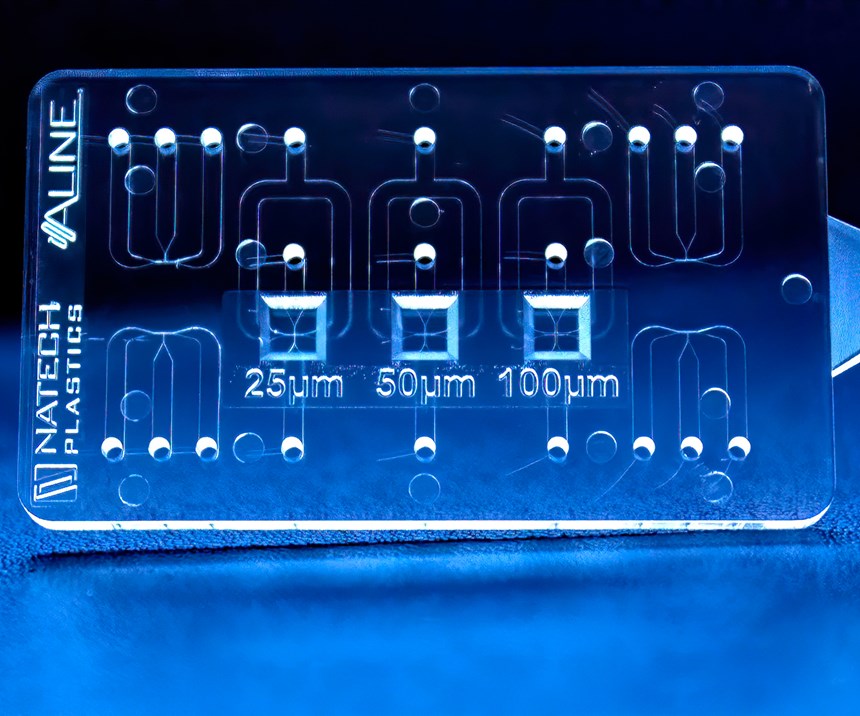

Natech utilizes advanced technology to make tooling inserts for microfluidic “lab-on-a-chip” diagnostic devices with microfeatures as small as 20-micron channels. Natech works with a European supplier that uses “LIGA” technology developed for microelectronics. It involves UV photolithography to create a nickel-alloy insert on a silicon wafer. Microfluidic devices are a growing market for Natech and a primary driver behind building its new clean room. (For more on LIGA technology, see “Micro Molds Make Micro Parts,” April 2004.)

Cost savings and efficiency gains in small increments are also valued. For example, Natech’s main production plant recently installed new lighting, which makes for a brighter work environment and saves energy. “We got a nice rebate from the power company,” Kachoui remarks.

And because the plant performs an average of nine mold changes a week, or as many as 12 in a busy week, it’s essential to make those changes as efficient as possible. Plant manager Domingo Hernandez initiated using mold-change carts that contain all the parts and tools needed for the job, so that no one has to leave the press to go hunting for a wrench, for example. There’s also a cart on the shop floor that contains all packaging materials, so that items like tape and labels are quickly available.

Operations manager Elizabeth Merrifield is looking forward to a leap forward in overall management effectiveness through installation of an MRP computer system from IQMS. “I manage everything that comes in and ships out, including all raw-material purchases. We didn’t have MRP before, so I check production numbers every morning on paper reports. Human error is inevitable. But this new computer system will automatically track inventory and how much material we need. It will also track production data and schedule orders and quality sampling. We will eventually go to barcode reading to make it even more automatic.” This capability will be especially valuable, she says, because the last five to 10 years have seen an upsurge in last-minute orders, when customers demand, I need this now! She adds that the IQMS system has an MRO module that will help in scheduling preventive maintenance.

MANAGING THE ‘TALENT POOL’

Apart from its investments in hardware and software, “Natech has made a lot of investments in management skills—a lot of training,” Kachoui points out. “We have identified the management skills our people need to complement their technical skills. Our goal is to help our people develop and help them develop others.”

About six years ago, Kachoui recalls, both quality and safety concerns demanded urgent attention. “We experienced some quality issues, and we lost some big clients. There were also safety issues that had to be addressed.” Kachoui embarked on a project to educate himself about quality. That search quickly led him to the teachings of W. Edwards Deming (1900-1993), a statistician and business consultant widely considered the “father” or “guru” of modern quality consciousness. The first book Kachoui read was “Dr. Deming: The American Who Taught the Japanese About Quality” by J. Rafael Aguayo, a student of Deming and professor at SUNY Stony Brook, N.Y., College of Business. “I reached out to him, and he answered a lot of my questions and helped me connect the dots,” says Kachoui, whose next step was taking a course from the W. Edwards Deming Institute.

The result was a surprise to Kachoui: “I thought I would learn about quality, but I found I was learning about management. I was learning about intrinsic motivation and mentoring, about changing my approach to people.”

The goal of management, he learned, is to nurture pride of workmanship. That comes down to understanding the difference between extrinsic motivation and intrinsic motivation. “Extrinsic motivation is about rewards and consequences, carrots and sticks. Intrinsic motivation is when the drive to perform comes from within: I want to do a good job because it feels good, because I want to accomplish something.

“It’s all about removing barriers to pride in workmanship. The number-one barrier is fear. The old ‘management by numbers’ or ‘management by results’ instills fear.”

How do you demolish the fear barrier? “When something goes wrong, you don’t hand out blame, but ask, What in our processes allowed that to happen?

“I learned about something called ‘fundamental attribution error.’ When something goes wrong, the human tendency is to assume that there’s something wrong with the person held responsible, who doesn’t work hard enough, doesn’t care enough, or isn’t smart enough. But we know our people—they are smart, they do care, they do work hard.”

Studying Deming led Kachoui to learn about “lean manufacturing,” a philosophy developed at Toyota and based in part on Deming’s principles of Total Quality Management. A key lesson for Kachoui was that “managers no longer police others’ behavior. Lean is not just about removing waste, it’s about removing frustration for your workers. Phase I of implementing Lean is respect for people—treating each other with respect. Phase II is improving your processes. A lot of companies try to skip Phase I and wonder why it didn’t work out. We are six years into Phase I, and Phase II is kind of happening on its own.”

Kachoui shared with others at Natech what he had learned about quality management. That led to weekly internal management training for the CEO, plant manager, quality-assurance manager, engineering team, and customer service.

“We also implemented three things: First, ‘Break down barriers across departments’ and ‘Remove fear,’ as Deming said, so people can work together to improve the system. We gather people from across departments together as a group. We facilitate group discussions and group decisions. We defined our mission, vision and values as a group and periodically revisit them as a group. We started treating our values as skills, hired to our values, and developed people to our values.

“Second, we express appreciation for contributions by saying, ‘Thank you.’ We hold a summer picnic and a year-end holiday party to thank people. At the holiday party we hand out Certificates of Appreciation to people for milestone years of service. You can see images of this on our Facebook page (facebook.com/natechplastics).

“Third, we acknowledge mastery of a skill. Each person has a Training Plan. When they move up a level, we update their plan. We use the training program to identify learning goals, skills and level of competency from novice through apprentice and practitioner to master.”

Kachoui and the firm’s quality-assurance manager, Dunham, took courses from the American Society for Quality (ASQ); they earned CQE (certified quality engineer) and CQA (certified quality auditor) certificates, respectively. In addition, Michael Botta, engineering manager, trained in Scientific Molding with John Bozzelli (a regular columnist for this magazine), Suhas Kulkarni (another PT contributor), and Beaumont Technologies’ AIM Institute. Botta then passed this learning on to Roane as a new hire from U.Mass-Lowell. The firm plans to send other employees for similar training.

All of this has reaped benefits. “We just got our ISO 13485 (international medical quality standard) certification in April. Our internal team made it happen. Our cost of quality has come down a lot, and our staff turnover rate is down tremendously—below 2%.”

In step with the internal quality-management training is a program for safety training. “Safety is an important part of quality,” says Kachoui. Natech now has safety training each quarter for all staff on all three shifts. The program covers everything from handling hazardous chemicals to ladder safety and eye protection. “At first they just listened quietly. Now they are so much more engaged. We have very lively meetings, where people come up with ideas to improve things they have noticed on the job, like adding covers to conveyors or padding for sharp edges. Each day when I come into the plant, I see some new improvement that somebody took the initiative to implement.”

Related Content

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

Read MoreDigital Manufacturing: Two Medical Molders Embrace Industry 4.0

‘Digitalization’ and ‘connectivity’ are loaded terms—shorthand for a whole new way of doing business. It can’t be accomplished in one go. But two Midwest molders in the sensitive medical field are already feeling the benefits of their initial steps in that direction.

Read MoreFor This Molder, Less Paper + More Data = Higher Productivity

At Tessy Plastics, going paperless means more than idle printers and fewer orders for three-ring binders.

Read MoreBack in the Family Business

In its 45th year, Precision Molded Plastics has carved out a technology and market niche, growing not just when opportunities arise but when they make sense, after its leader changed careers to keep the family business from changing hands.

Read MoreRead Next

Micro Molds Make Micro Parts

Molded parts barely visible to the naked eye require non-traditional methods for making high-precision micro-injection molds. Micro-tooling R&D is being led by technology institutes, research firms, and a few highly specialized mold makers.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More