3D Printing of “Porous” Tools Awarded Walmart Research Grant

What if you could build a tool that had just the right amount of material it needed in just the right places?

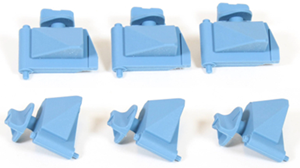

Additive manufacturing has long been used to add conformal cooling channels to injection molds, maximizing heat transfer efficiency, but what if it could be taken further, using just the amount of material needed in just the right place to create a porous tool sub-structure that would lessen the tool’s cost and weight while boosting its efficiency?

That’s exactly the goal of a team of researchers at the Purdue School of Engineering & Technology at Indiana University–Purdue University Indianapolis (IUPUI) who received a grant from retailer Walmart’s U.S. Manufacturing Innovation Fund and the United States Conference of Mayors.

The two-year $291,202 grant will fund IUPUI’s research project: “Optimal Plastic Injection Molding Tooling Design and Production through Advanced Additive Manufacturing.” The project’s goal is to reduce the cost and increase the performance of U.S.-made tooling through what it calls “multiscale, thermo-mechanical topology optimization methods and metal additive manufacturing.”

Andrés Tovar, an assistant professor in IUPUI’S Department of Mechanical Engineering, said the goal is to create a “free-form, lightweight, innovative structure of maximum performance….a lightweight structure of maximum mechanical stiffness and maximum heat dissipation.”

IUPUI is working with Hewitt Molding Company (Oakford, Indiana) and 3D Parts Manufacturing (Indianapolis) on the project, with 3D Part Manufacturing using its EOS EOSINT M 280 direct metal laser sintering system to build the porous tools.

A sample product confirmed the potential benefits, according to Tovar. He estimates that “conservatively” the optimized porous tool would allow 30% cost reduction, derived directly from material saving, as well as a 20% performance increase based on greater cooling efficiency and a shorter cycle time.

In addition, Tovar’s team expects to see tool life increase of at least 10% compared to conventional cavity molds, with a lower cost per plastic part (from $0.62/piece to $0.58/piece for a given industrial test case), and increased part quality by eliminating imperfections resulting from non-uniform cooling.

“The cost of 3D printing is proportional to the weight,” Tovar said, “so, what we propose is: we can take those designs of molds and redesign them by changing the solid fill material with porous material. So we can have complex molds with conformal cooling in a porous structure.”

Done correctly, Tovar notes the novel design will have no deleterious impact on the tool’s integrity. “Mechanically it’s going to maintain the structural stability; it doesn’t compromise any structural performance; it’s not going to deform; it’s not going to change over time, due to deformation. Wherever it needs to have the material, it will put the material in there.”

Over the next two years, Tovar said his team, in conjunction with Hewitt and 3D Parts, will create production tools to further test the technology, and fine tune the predictive models and algorithms that determine the tool’s cellular structure. In addition, molding trials will allow the researchers to incorporate processing parameters into the algorithm. Above all, the trials will create data, something currently lacking in the additive manufacturing field.

“There is very little data out there available about the thermal and mechanical properties of layered materials using additive manufacturing,” Tovar explained, “so we want to populate that data base.” Better data = better algorithm.

If the predicted results are proven out, Tovar believes that additive manufacturing could encroach on long-held subtractive manufacturing techniques.

“We believe porous structures are going to be more and more common in many thermo mechanical components,” Tovar said. “If you put the holes in in the right way then the mechanical performance is not going to be decreased and the thermal performance is going to be higher. We believe it will be cheaper for the manufacturer.”

Oregon State partners with Arburg

Given how many of the products it sells are made from plastics, with all of those requiring a tool or die, Walmart is keenly aware how important advances in mold and die production could be as it works to ramp up U.S. sourcing.

In addition to Tovar and IUPUI, Sundar V. Atre and Rajiv Malhotra, researchers at Oregon State University, were awarded a $590,000 grant from the Walmart Foundation. Their research project involves “novel metal additive manufacturing processes for fabricating low cost plastic injection molds.”

Oregon State will partner with MTI Albany (direct laser sintering), North American Höganäs (tailoring metal powders) and injection molding machine supplier Arburg (testing mold performance).

Atre told Plastics Technology that his team is developing two additive manufacturing approaches to create molds, with tool steel as the base material. In an Oregon State release, Atre estimated their technique could reduce mold-making costs by 40-50% noting:

“Current practices for fabricating these molds are labor-intensive and costly, and much of the mold material is wasted as metal chips. [Additive manufacturing] will give U.S. manufacturing an edge.”

Related Content

420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's Additive Manufacturing Technology is Designed for Precision Tooling

Read MoreBusiness Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

Read MoreGetting into Plastics Additive Manufacturing? Avoid these Six Common Errors

There are a lot of 3D printing technologies out there, and it’s not uncommon for processors new to additive manufacturing to get tripped up. Here are some typical snafus, along with advice on how to avoid them before you start making parts.

Read MoreKraussMaffei Launches Two Additive Manufacturing Lines at K 2022

Long established in injection molding, extrusion and polyurethane reaction process machinery, 184-yr-old KraussMaffei prepares to enter the industrial additive manufacturing market.

Read MoreRead Next

Wal-Mart's Made in America Pledge and Plastics

The world's largest retailer has committed to sourcing and additional $50 billion in U.S. made goods over the next decade; what does it mean for plastics processors?

Read MoreWal-Mart's Made in America Pledge and Plastics

The world's largest retailer has committed to sourcing and additional $50 billion in U.S. made goods over the next decade; what does it mean for plastics processors?

Read MoreWal-Mart's Made in America Pledge and Plastics

The world's largest retailer has committed to sourcing and additional $50 billion in U.S. made goods over the next decade; what does it mean for plastics processors?

Read More

.png;maxWidth=300;quality=90)