Bayer Exploring Use of CO2 to Make Plastics

With one application near commercialization, Bayer's research into CO2 as a raw material for making plastics looks promising.

As part of its Dream Polymers research project launched in 2009, Bayer MaterialScience researchers have been exploring the use of CO2 as a new raw material for making plastics, among other uses. More recently they have succeeded in significantly reducing the need for petroleum in a polyurethane foam application.

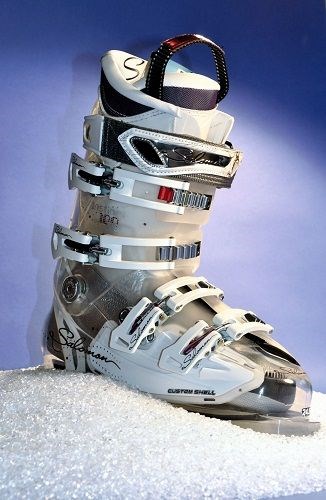

Moreover, researchers have demonstrated that the new process also extends the range of plastics that CO2 can be used to produce, according to project manager Christoph Gurtler. “For example, it is now possible to manufacture thermoplastic polyurethanes, films and casting elastomers in this way…for applications such as automotive interiors, cable sheathing and sporting goods such as ski boots,” he says.

The use of CO2 in this process is twofold. First, the greenhouse gas in incorporated directly into a new kind of precursor (polyoxymethylene polycarbonate polyol), replacing 20% of the petroleum. Second, it is used indirectly, producing a chemical that is incorporated into the precursor for a further 20% savings in petroleum. According to Gurtler, the technology has been used to produce a key component (the polyol) for high-quality polyurethane foam for mattresses which is near commercialization. “The proportion of petroleum in this chemical is 80%. We have now succeeded in reducing the petroleum content for making plastics to just 60%,” he says.

This long-range Dream Polymers research project is supported by the German Federal Ministry of Education & Research, as well as the CAT Catalytic Center, Leibniz Institute for Catalysis, and the Fraunhofer Institute for Chemical Technology.

Related Content

-

Infrastructure May Prove Big Landing Spot for Recycled Plastics

As the government funds infrastructure improvements, a hot topic at NPE2024 – exploration of the role recycled plastics can play in upcoming projects, particularly road development.

-

Plastic Compounding Market to Outpace Metal & Alloy Market Growth

Study shows the plastic compounding process is being used to boost electrical properties and UV resistance while custom compounding is increasingly being used to achieve high-performance in plastic-based goods.

-

Borealis and Partners Move Forward with Crosslinked PE and PP Pipes Based on Renewable Feedstock

The company’s partnerships in these new drop-in solutions significantly advances carbon footprint reduction.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)