Breakthrough Methodology Directly Quantifies Recycled Content in Plastics Packaging

University of Manchester team’s novel fluorescence-based spin-out technology provides a rapid and reliable analysis method to measure and certify recycled content in a wide range of plastics.

We were recently alerted to an innovative spin-out tracking technology, called ReCon^2, for what appears to be a breakthrough for the direct quantification of recycled content in plastics and plastic packaging. ReCon^2 is being developed by a team from Manchester University led by Michael Shaver, professor of Polymer Science and director of the Sustainable Materials Innovation Hub, and Natalie Mera-Pirttijarvi, the project manager at the University of Manchester Innovation Factory.

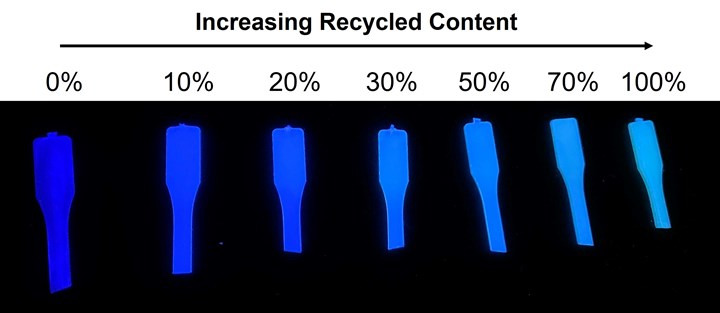

ReCon^2 (ReCon squared), short for “Recycled Content Reconnaissance”, uses minute quantities of unique fluorescent tracker additives and fluorescence spectroscopy to analyze the recycled content of plastic materials or articles. Not only does it measure the intensity of the fluorescence as an indicator for the concentration of the additive, but the spectrum changes as the recyclate is diluted with virgin (and recycled) polymers. As such, recyclers/compounders can produce masterbatches with a traceable recyclate concentration, and its “fluorescent signature” can be tracked to the final products to be compared and validated when recycled-content claims are audited.

The Manchester team’s Recon^2 approach can be applied directly to a plastic material or product, or a section or component of it, and used as a QC method. Within minutes, the recycled content of the product can be reliably assessed accurately and precisely to about a 5wt% level. The method can be expanded to a multi-pronged analytical approach to minimize fraudulent imitations of recycled content. The technique has shown success with various high volume packaging plastics - HDPE, LDPE, PP and PET - and is also expected to be applicable to PS, PVC and more specialty plastics. Although it was developed for mechanical recycling, it is anticipated that it can also be adapted for chemically recycled feedstocks.

While the technology and its applications are still under development, the Manchester team has been actively contacting companies along the plastics, packaging and recycling production chains and related organizations to explore interest in the technology. This encompasses both mechanical and chemical recycling as a complement or alternative to present chain of custody, ISCC+ and mass balance certifications methods. In contrast to these existing methods, ReCon^2 is able to provide a direct measurement of recycled content in individual polymer feedstocks or packaging items rather than just an average over total production.

Currently, there is no commercially available fast and accurate quantification method to determine the recycled plastic content in a plastic product, particularly as a simple and inexpensive quality QC method. While the Mass Balance Approach is the current methodology for determining the percentage of recyclate in a manufacturer’s products and packaging, there is considerable concern with factors such as high costs, traceability, data security and auditing challenges, especially in identifying and measuring the recycled content in a specific product or package.

According to the Manchester team, accurate and rapid analytical determination of recycled content (and thus tax liability) using other previously established physical characterization methods, such as rheology or differential scanning calorimetry, is hugely challenging. This is because the results largely depend upon the conditions of the recycling process itself and are strongly affected by factors such as plastic degradation, presence of additives and polymer feedstock variations. Moreover, such techniques are time-consuming, expensive, and specialized, requiring complex equipment and expert operators.

By contrast, ReCon^2 is completely process independent, promising a fast, accurate, inexpensive and robust solution to facilitate the assessment of plastic packaging taxes and show conformity with the legal requirements, taxes and commitments made by many companies across the supply chain. There will only be a minor impact on recyclate cost, the tracking marker materials are FDA approved for food contact packaging, and there are no adverse effects on mechanical and chemical properties of recyclate or taste/odor generation for food and beverage packaging.

ReCon^2 could therefore represent a true “platform” methodology, with the potential to transform the way that the plastics industry utilizes recycled content, in part by disincentivizing greenwashing and waste fraud practices that devalue circularity and erode public trust in plastic recycling.

The Manchester team is now focusing on further developing and scaling-up the technology for packaging applications and is investigating detection limits, compatibility with common additives, dyes and pigments used in packaging polymers, and large scale (multi-ton) trials.

The University of Manchester Innovation Factory is looking for feedback regarding this approach and technology from potential investors. The Manchester team are also interested in having discussions with potential collaborators/early adopters, particularly in the packaging and recycling supply chains, to accelerate the market use and commercialization this technology.

Related Content

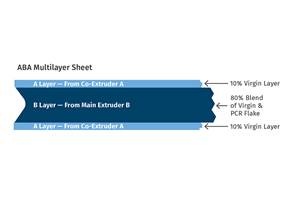

Thermoforming PCR: An Equipment Supplier’s Pointers

Thermoforming PCR is not radically different from forming virgin, but variation in recycled materials can require extra care to get a consistent end result. Start by examining every aspect of the process from the sheet (and extrusion process if run inline) to the final trim.

Read MoreRecycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

Read MoreEvolving Opportunities for Ambitious Plastics Recycler

St. Joseph Plastics grew from a simple grinding operation and now pursues growing markets in recycled PP, food-grade recycled materials, and customized post-industrial and post-consumer compounds.

Read MoreFungi Makes Meal of Polypropylene

University of Sydney researchers identify two strains of fungi that can biodegrade hard to recycle plastics like PP.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More