New Pilot Project for Closed-Loop Recycling of Single-Use Face Masks

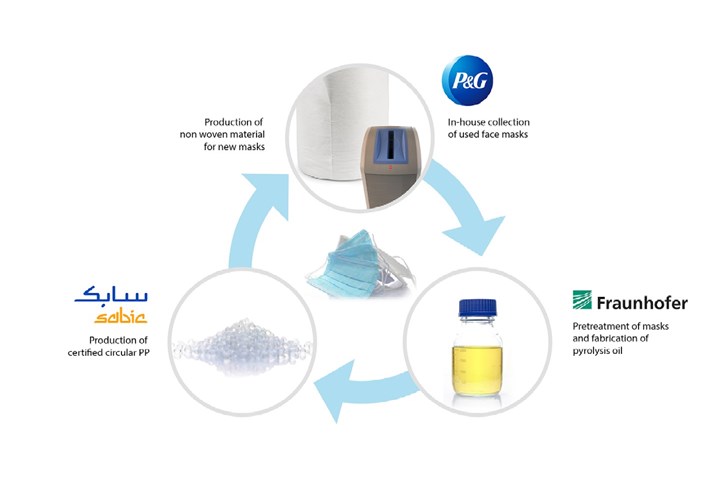

Fraunhofer Institute UMSICHT, Sabic and Procter & Gamble (P&G) have joined together for this project to demonstrate the feasibility of closed-loop recycling for single-use face masks.

Since spring of 2020, masks have been prevalent around the world. But while they provide much needed protection, these single-use masks add another wrinkle to the growing global waste issue.

This is why the Fraunhofer Institute UMSICHT, Sabic and Procter & Gamble (P&G) have collaborated on a circular economy pilot project that aimed to demonstrate the feasibility of closed-loop recycling of single-use face masks.

Due to COVID-19, use of billions of disposable face masks is raising environmental concerns especially when they are thoughtlessly discarded in public spaces, including parks, open-air venues and beaches. Apart from the challenge of dealing with such huge volumes of essential personal healthcare items in a sustainable way, simply throwing the used masks away for disposal on landfill sites or in incineration plants represents a loss of valuable feedstock for new material.

“Recognizing the challenge, we set out to explore how used face masks could potentially be returned into the value chain of new face mask production,” said Peter Dziezok, director R&D open innovation at P&G. “But creating a true circular solution from both a sustainable and an economically feasible perspective takes partners. Therefore, we teamed up with Fraunhofer CCPE and Fraunhofer UMSICHT’s expert scientists and Sabic’s T&I specialists to investigate potential solutions.”

As part of the pilot, P&G collected used face masks worn by employees or given to visitors at its manufacturing and research sites in Germany. Although those masks are always disposed of responsibly, there was no ideal route in place to recycle them efficiently. To help demonstrate a potential step change in this scenario, special collection bins were set up, and the collected used masks were sent to Fraunhofer for further processing in a dedicated research pyrolysis plant.

“A single-use medical product such as a face mask has high hygiene requirements, both in terms of disposal and production. Mechanical recycling, would have not done the job,” said Alexander Hofmann, head of department recycling management at Fraunhofer UMSICHT. “In our solution, therefore, the masks were first automatically shredded and then thermochemically converted to pyrolysis oil. Pyrolysis breaks the plastic down into molecular fragments under pressure and heat, which will also destroy any residual pollutants or pathogens, such as the Coronavirus. In this way it is possible to produce feedstock for new plastics in virgin quality that can also meet the requirements for medical products,” adds Hofmann, who is also head of research department of advanced recycling at Fraunhofer CCPE.

The pyrolysis oil was then sent to Sabic to be used as feedstock for the production of new PP resin. The resins were produced using the widely recognized principle of mass balance to combine the alternative feedstock with fossil-based feedstock in the production process. Mass balance is considered a crucial bridge between today’s linear economy and the more sustainable circular economy of the future.

“The high-quality circular PP polymer obtained in this pilot clearly demonstrates that closed-loop recycling is achievable through active collaboration of players from across the value chain,” said Mark Vester, global circular economy leader at Sabic. “The circular material is part of our TruCircle portfolio, aimed at preventing valuable used plastic from becoming waste and at mitigating the depletion of fossil resources.”

Finally, to close the loop, the PP polymer was supplied to P&G, where it was processed into non-woven fibers material. “This pilot project has helped us to assess if the close loop approach could work for hygienic and medical grade plastics,” said Hansjörg Reick, P&G senior director open innovation. “Of course, further work is needed but the results so far have been very encouraging.”

The entire closed-loop pilot project from face mask collection to production was developed and implemented in only seven months. The transferability of advanced recycling to other feedstocks and chemical products is being further researched at Fraunhofer CCPE.

Fraunhofer, Sabic and Procter & Gamble have demonstrated the feasibility of closing the loop on face masks to help reduce plastic waste and mitigate fossil resources depletion.

Related Content

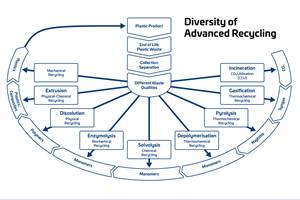

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreReversing Logistics for Plastic Film Recycling

Learn how Mainetti built a circular supply chain for clear film packaging.

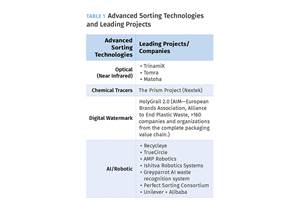

Read MoreRecycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreNew Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

Read MoreRead Next

Novation Industries Ramps Up Unprecedented Production Volume for Face Masks

Molding parts every 18 to 28 seconds, filling a box every minute, and shipping an average three truckloads of product every day—Novation has risen to the coronavirus challenge.

Read More20 Good Things to Come Out of 2020—Part 4

Good news was there if you knew where to look for it—in the pages of Plastics Technology magazine or right here on our website. Here’s a review of headlines you can feel good about.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More