Plastics Processors Who Hire ‘Second-Chance’ Workers Do Well by Doing Good

Two blow molders with long-standing programs of hiring formerly incarcerated low-level offenders have helped these individuals re-enter their communities and have benefited from an additional resource during chronic labor shortages.

Mel O’Leary, president and CEO of blow molder Meredith-Springfield Associates, was recently honored for hiring hundreds of people in two decades of collaborating with Massachusetts’ Hampden County Sheriff’s Department’s second-chance employment program for low-level offenders. (Photo: Matthew Naitove)

“Do well by doing good” is advice often attributed to Benjamin Franklin — a directive characteristically both moral and practical. The briefest internet search will reveal that this principle is integral to today’s concepts of sustainable management, yielding references to McKinsey, Harvard Business Review, Penn Wharton, Forbes, and so on. By chance, I recently happened upon two plastics blow molders who have taken it to heart, with good results for their communities and their companies.

Last month, Mel O’Leary, president and CEO of Meredith-Springfield Associates, Inc. (MSA) in Ludlow, Mass., was honored by the Hampden County Sheriff’s Office’s All-Inclusive Support Services (AISS) for his two decades as a “second-chance” employer in collaboration with AISS. O’Leary, 69, co-founded MSA, which will celebrate its 40th anniversary this year. I interviewed him for a feature profile of his company, which specializes in bottles and technical articles made by extrusion blow and injection-blow molding, in our March 2019 issue. The firm operates 14 blow molders and employs around 100 people.

“I sincerely appreciate this honor,” O’Leary said at the ceremony, but what’s more important to me is the impact this program has on so many lives. It doesn’t just benefit ex-offenders, but also their families and communities. People make mistakes, and giving them a chance to turn their lives around is very important to me. We’re proud to have helped hundreds of formerly incarcerated people in the last 20 years to transition back into the community with gainful employment.”

In a subsequent phone conversation, I asked O’Leary how the process works. He credited Hampden County in Western Massachusetts as having “the most innovative and progressive program — and one of the lowest recidivism rates — in the country.” He explained, “It starts with their first day in jai. They can’t just sit in their cell. They must engage in education, vocational training, or some constructive activity for at least 40 hours a week.”

“We’re in regular communication with the Sheriff’s Office. They have a whole staff at the Corrections Dept. just to find employment for pre-release and post-release offenders. This is for low-level offenders who have shown good behavior.

“We let them know we have a vacancy, and they’ll look for three candidates that we can interview. They’ve known us for 20 years, so they know who would be a good fit with us. The beauty part is that they offer us pre-qualified candidates.”

MSA usually hires pre-release offenders with three to six months left on their jail sentence. The Corrections Dept. provides a bus for transportation to and from our plant (only three miles from the county jail) at the beginning and end of shift.

“These hires are not treated any differently from regular employees,” O’Leary says. “They get the same pay, raises and reviews. We deposit their paychecks at the jail, which deducts for room and board and gives a weekly cash allowance of $25 to the workers. The rest is placed in a bank deposit for the workers until they are released.

“We also get some post-release offenders on probation with an ankle bracelet. Either way, Corrections provides regular monitoring and supervision for the first six months to see that everything is working out.

“Many of these hires are younger people for whom this is their first real job. We give them mostly unskilled and semi-skilled jobs as a packer/inspector, material handler or automation operator. But we also get some skilled workers—welders, heavy equipment mechanics, licensed forklift operators. We even had a teacher and an architect.”

Average tenure of these second-chance hires is about six months—but that’s the same as, or better than, other entry-level unskilled workers, O’Leary says. “We have zero turnover at the technician level and above—but below that level, it’s a revolving door. We have 50% annual turnover no matter what we pay or what we do. Availability of some labor through Corrections provides us relief from these hiring difficulties.”

Some second-chance hires have stayed with MSA for up to 15 years. “One even left and came back,” O’Leary recalls. These longer-term successes include one woman supervisor, two warehouse forklift operators, as well as machine mechanics and automation operators.

O’Leary has encouraged other manufacturers to follow his example, with some (limited) success. “I always preach and promote this program. I’ve seen how it changes lives.”

John Sewell, CEO of CKS Packaging (center), with brothers Scott, co-COO in charge of operations (left), and Drew, co-COO for sales. Their Second Chance program for low-level offenders and recovered drug addicts has produced long-term employees even at the managerial level. (Photo: CKS Packaging)

I first encountered the phrase “second chance” about a year ago in talking with John and Drew Sewell, two of three brothers in the second generation running family-owned CKS Packaging. Based in Atlanta, the firm has two dozen locations nationwide with over 400 blow molding machines and employing around 3000 people.

Close to 300 of those employees came to CKS through the company’s Second Chance program started by v.p. of manufacturing Lloyd Martin. Says Drew Sewell, COO for sales, “We hire out of prison when nobody else will — nonviolent, non-sex offenders. We don’t judge.” In addition, the company offers a rehab program for people who want to kick alcohol or drug addiction. “After a year in the program we will hire them,” Drew says.

The company’s Second Chance hires include shift supervisors, technicians and even a plant manager. “We’re starting a veterans outreach program now,” Drew adds.

John Sewell, CEO, cites the company’s policy of “celebrating the dignity of every human life. We treat our employees with dignity and respect. In return, they would walk through a wall for us. Some employees have been with the company for 30, 40 and even 50 years. “We have fourth-generation employees in the same family working here.” This extraordinary loyalty has helped the company deal with labor shortages, especially during the recent pandemic. “We’re like everyone else in needing more workers. But when we’re down a few people due to sickness or otherwise, everyone chips in to make up for it.”

Related Content

The Cost of High Employee Turnover in Injection Molding: Why Retention Matters

Starting in molding in 1993 and clocking in for nearly every job on the floor over the intervening decades, I’ve seen all sides of the hiring, training and retention process in the industry. Here are my thoughts on how to keep your most important asset — your people.

Read MoreTeaching Kids About the ‘Magic’ of Manufacturing

Making something out of (almost) nothing is an ‘eye opener’ for youngsters in their first exposure to plastics processing.

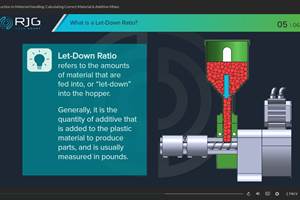

Read MoreLearn Fundamentals of Materials Handling in Self-Paced Online Course

Learn about equipment, procedures and maintenance for material handling related to injection molding.

Read MoreMold-Change Time Targeted with Training, Technology

Engel is offering technology and training to molders to help them optimize their mold-changing process.

Read MoreRead Next

Blow Molders Are Expanding

Three blow molders of large and small products are adding machines and manufacturing space.

Read MoreAre We Having a Good Day? Real-Time Production Data Has Answers for a Custom Blow Molder

“Information automation” is one of the keys to running a successful custom blow molding business for Meredith-Springfield Associates.

Read More‘We Don’t Shy Away from a Challenge’

Meredith-Springfield thrives on technically difficult blow molding jobs that others avoid. Its latest pioneering effort is pushing the limits in the new field of EPET.

Read More