Recycling Terminology Can Be a Minefield, So We Should Tread Lightly

Loose propagation of terms like “recyclable” and “compostable” has already brought down government regulations on labeling. The plastics and packaging industries should take that to heart with other recycle-related language. Like “monomaterial” for example.

New Polyfoil EcoPro squeeze-tube body structure from Hoffmann Neopac is praised for excellent barrier properties, 30% reduced wall thickness, use of up to 60% PCR and recyclability in the HDPE stream. EVOH constitutes around 2% of the structure – is that truly “mono-material”? (Photo: Hoffmann Neopac)

Today everybody wants to be considered “green,” but nobody wants to be accused of “greenwashing.” Unfortunately, being overly free with progressive-sounding environmental terms ends up constricting our freedom. We’ve already been told by government regulators when we can or can’t say something is “recyclable” or “compostable.” There are ongoing discussions at various regulatory levels about when we can call something “recycled” and even what does or does not constitute “recycling.”

Many in the plastics and packaging industries have taken this lesson to heart. Nowadays, when I see announcements about the sustainability of materials, they are often backed up by certifications from recognized authorities. Nonetheless, I see evidence of the need for continued vigilance to avoid stepping into verbal potholes.

Just last week, I saw an announcement from the Swiss-based global packaging firm Hoffmann Neopac about the launch of a new product at the Luxe Pack NY trade show the week before. The new Polyfoil EcoPro squeeze tubes are described as “mono-material double barrier tubes … ideal for personal care and cosmetic products.” Available in capacities of 50 to 200 ml, these tubes contain up to 60% EU food-grade post-consumer recycled (PCR) HDPE and have a body wall thickness of 0.35 mm, which is 30% less than the company’s standard Polyfoil barrier tubes. Their CO2 footprint is said to be 40% less than “standard coex tubes.” They can use virgin or recycled (up to 70%) EU food-grade HDPE in the shoulder and flip-top or screw cap.

Hoffmann Neopac says the new tubes come with EU food compliance certification as well as a Grade A recyclability rating from the EU’s RecyClass sustainability verification organization, and Suez Grade A rating from Suez Group, the French-based global provider of “circular solutions” in water and waste materials.

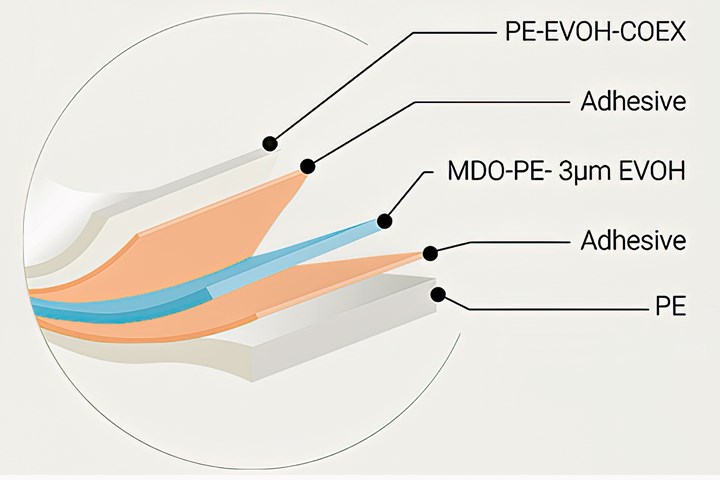

I was intrigued by the description of these tubes as “mono-material” and “double barrier” as well as the company’s claim that they are “fully recyclable in the HDPE stream.” On a Neopac web page devoted to the product I found the “exploded view” of the laminate layer structure shown here. You’ll notice, as I did, that there are two layers that combine EVOH with HDPE: One is a coextruded layer and the other an MDO-HDPE layer with a 3-micron EVOH adhesive-bonded layer. I guess that’s what they mean by “double barrier.” There are also two adhesive layers. Not shown here is the “overcoated” outer layer of the tube, containing up to 70% PCR-HDPE.

So, strictly speaking, we’re not dealing with a “mono-material” tube body – it comprises two materials, or really three, counting the adhesive. The key, however, is that the EVOH constitutes only around 2% of the structure, so the tube is certified recyclable in the HDPE stream – just as if it were mono-material HDPE. A member of the Neopac team confirmed that this is what really counts, more than the precise material composition, and is how the “mono-material” label is justified.

Okay, I can see that argument. But it still leaves me a bit uneasy. I wrote here recently about the accelerating trend toward “mono-material” packaging (and some durables, too). I was impressed by the creativity that allows all-polyolefin structures to replace barriers based on aluminum foil, metallization or incompatible resins such as nylon, PVDC or PET. Even then, I noticed that some “all-polyolefin” products, such as new pouches from Toppan, Inc. of Japan, actually employ vapor-deposited layers of aluminum oxide or silicon oxide (i.e., “glass”), though they're still recyclable in polyolefin streams.

Burdened with an editor’s commitment to precision and accuracy in language, I’m beginning to wonder about the prudence of packaging manufacturers tying themselves to language like “mono-material” and “all-polyolefin” when that’s not truly the case. Better to stick with the real point: “recyclable in the PE (or PP) stream.” Without diminishing the importance of this evolution in packaging toward greater recyclability, let’s not get off on the wrong foot by mis-labeling the product and possibly inviting regulatory correction later on.

Plastics and packaging producers are often criticized for supposedly exaggerating the achievements of recycling. So let’s not open ourselves up to another claim of misrepresentation. The real story of package recyclability in the PE or PP stream is a big deal on its own. When the facts are favorable, stick with the facts.

Your comments are welcome. (mnaitove@ptonline.com)

Related Content

Resins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

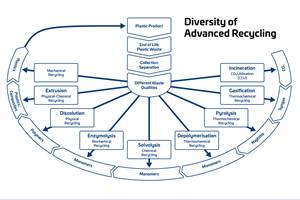

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreCalculating an Injection Molding Machine’s Carbon Footprint

Arburg has utilized the ISO TS 1467:2018 standard, which determines the greenhouse gas emissions of a product, to help its customers calculate the product carbon footprint (PCF) of its injection molding machines.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)