Rethinking the Injection Screw: Is It a Trend?

Renowned screw designer Robert F. Dray wrote to me recently, lamenting that injection molding screw design has not received the kind of attention that the extrusion industry has paid to perfecting this fundamental processing component.

Renowned screw designer Robert F. Dray wrote to me recently, lamenting that injection molding screw design has not received the kind of attention that the extrusion industry has paid to perfecting this fundamental processing component.

“It is unfortunate that the injection molding industry has not placed the emphasis that is should on screw design and the advantages of lower melt temperatures with advanced screw design,” Dray said.

Things may be changing. In fact, it seems to be growing almost fashionable to question the very foundations of injection screw design that have been accepted for the past 60 years.

Item: Spiral Logic Ltd. of Hong Kong has developed a zero-compression screw that turns conventional wisdom on its head: Melting the resin is accomplished entirely by conductive heating from the heater bands, not by frictional shear. This is said to cure numerous ills: inconsistent melt temperature, pressure, density, and viscosity, as well as resin degradation and resulting “black specks.” One precision molder of medical parts, Makuta Technics, Shelbyville, Ind., swears by the SL screw. It and its associated molding company in Japan have equipped more than 100 machines with this technology. Makuta uses Sumitomo (SHI) Demag all-electric machines (Strongsville, Ohio), which are available with the SL screw. (Learn more about the SL screw here and about Makuta here.)

Item: A somewhat similar conclusion was reached by Xtrude2Fill in Loveland, Colo., which also exclusively uses conductive heating rather than frictional shear to melt the resin in the barrel. This is only one unusual aspect of an unconventional machine design that uses a fixed screw to extrude into the mold—essentially taking the injection out of injection molding. The concept was presented at our Molding 2016 Conference in March (see here for a report).

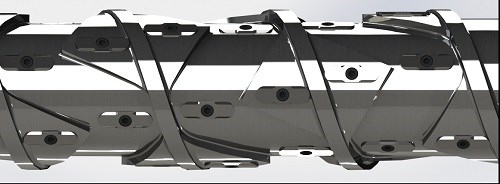

Item: Bob Dray’s firm, R. Dray Mfg., Hamilton, Tex., has addressed what it sees as the deficiencies of conventional injection screw design with the new All-Purpose Screw (APS). Dray says this special mixing screw (see photo), which can be easily modified to process a wide range of resin types and melt viscosities, offers the flexibility promised, but not delivered, by the so-called “general-purpose” injection screw, which Dray calls the “no-purpose” screw. (An exclusive in-depth report will appear in our June issue.)