Absolute Haitian Opens Its First U.S. Machine Assembly Plant

South Carolina operations center to assemble and test larger presses and stock machines for faster delivery.

In May, Absolute Haitian Corp. opened its first U.S. assembly plant for injection machines from Haitian International in China. Measuring 116,000 ft2, the just-completed building in Moncks Corner, S.C., near the port of Charleston, houses not only manufacturing and warehouse space, but also demonstration, training, spare-parts, and sales facilities. Equipped with drive-in dock, two 25-ton cranes, one 50-ton crane, and a central chilling system, the new operations center will assemble and test larger presses—meaning, to start with, roughly 700 tons and up. These will include mainly Jupiter two-platen, servohydraulic machines; Jenius hybrid two-platen machines; and servohydraulic Mars 2S toggle presses—Haitian’s top seller in the U.S. A mold-test area it equipped with individual chillers and temperature-control units (TCUs) to duplicate conditions in the customer’s plant. The new plant will bring in major mechanical subassemblies from China, as well as controls and other electrical and hydraulic components from various domestic and international suppliers.

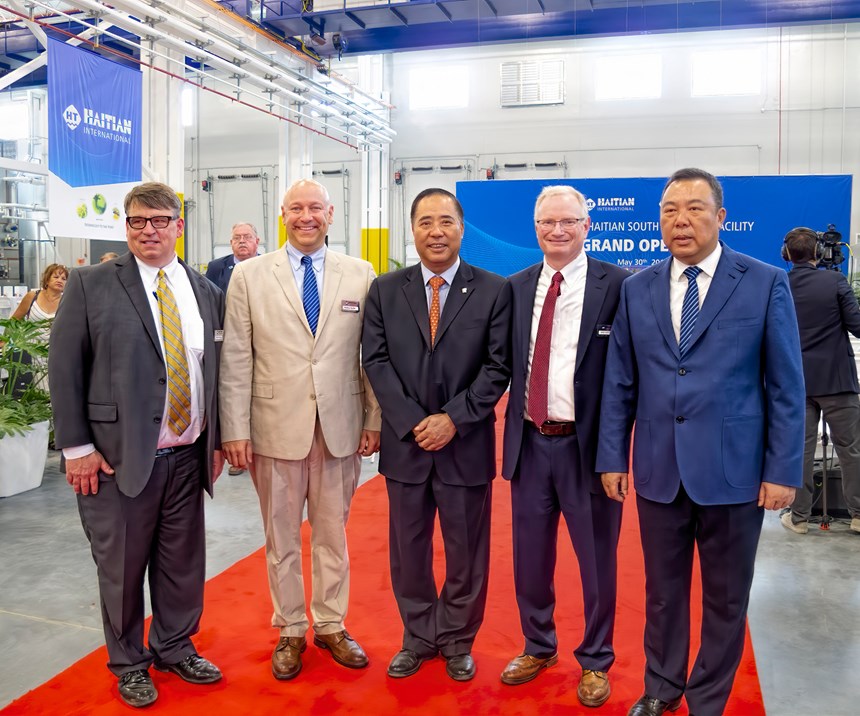

The grand opening ceremony was attended by the CEOs of both the Haitian Group and Haitian Plastics Machinery, as well as the three co-owners of Absolute Haitian—Nathan Smith, Michael Ortolano and Glenn Frohring. The new facility “positions us well to reduce lead times on delivery and enhance support to our customers,” said Ortolano. On display at the opening event were a Mars 2S MA 3200 (320 metric tons), Jupiter JU 6500 II, Jenius JE 6500, Venus VE 2300 all-electric unit, and Zeres ZE 2300 electric press with integrated hydraulics for core pulls—Haitian’s fastest growing line in the U.S. At that time, the plant held in stock an additional 45 or so Mars, Zeres and other machines from 60 to 190 m.t. As explained by Frohring, customers benefit not only from the large stock of machines for quick delivery, but also from the ability of customers to attend run-off of a large press here rather than in China. The new assembly capability also gives Absolute Haitian added flexibility because drives, for example, may be interchangeable between different machines. Frohring also noted that the new tariffs have only a small effect on prices of these machines, which remain highly competitive.

It was announced at the event that Absolute Haitian just broke ground for an even larger assembly plant—259,000 ft2—with similar capabilities in Mexico, due for completion in two years.

Related Content

-

Midtonnage Hybrid Range With Compact Footprint Launches

NPE2024: Milacron has the global launch of its new M-Series injection molding machine line featuring a large clamp stroke as standard in a line of midtonnage, compact-footprint machines.

-

Custom Injection Molder Plugs into All Electric Machines

Formerly a showroom for early-aughts-era Van Dorn hydraulics, the newest additions to Drummond Industries’ transforming fleet are all-electric Niigata injection molding machines.

-

All-Electric Press Gets U.S. Debut

NPE2024: For the first time, Arburg will make a global premier of a machine outside Germany with the new Allrounder 720 E Golden Electric among its 13 exhibits — seven in its own booth — in Orlando.