APJeT Targets Plastics with its Innovative Air Plasma Technology

Having made its mark in the textiles industry, APJeT sets sights of PE and PVC parts pre-treatment printing market.

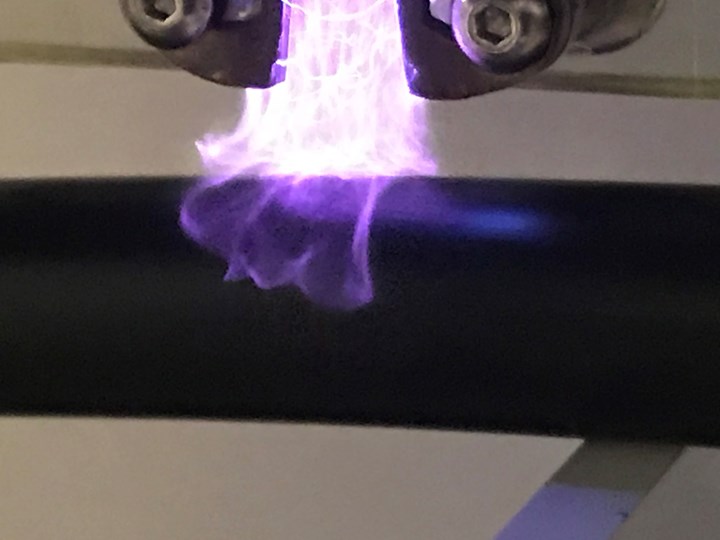

APJeT, Inc., Morrisville, N.C., with its innovative pre-treat plasma technology, well known in the textiles industry, has now set its sights on the plastic parts pre-treatment printing market--when marking or labeling is required. Eliminating the need for heat and chemicals for substrate preparation prior to dying or printing, the APJeT cold plasma process has been shown to increase wettability and adhesion, while reducing safety risks, environmental impact and degradation of the plastic substrate material.

APJeT’s pre-treat plasma technology is designed for application with multiple types of plastic parts, including: HDPE, PP and PVC. APJeT plasma is generated at atmospheric pressure and industrial line speeds using inexpensive gasses. The plasma systems are carefully engineered to cause powerful chemical surface reactions without altering the bulk strength and other desirable properties of the substrate. By changing the surface tension of a plastic substrate, the plasma process makes it hydrophilic (water-loving), increasing wettability and promoting superior adhesion by allowing water-based inks and dyes to be more easily absorbed into and bonded with the substrate.

Said APJeT CEO, Bentley Park, “When marking, printing or labeling must be clearly legible, dimensionally accurate, and wear- resistant; our cold plasma technology achieves maximum performance with minimal chemistry for HDPE manufacturers.”

APJeT has recently partnered with a global manufacturer of infrastructure conduit for commercial scale testing of its plasma technology.

APJeT has historically utilized its proprietary air plasma technology for the polymerization of monomeric coatings on materials in the textile industry. The company offers water and oil repellency, anti-microbial, wicking, and flame retardant finishes for a variety of markets.

Related Content

-

Ultrasonic Inserts and Heat Staking Kits for Thermoplastics

Made from brass with inch or metric threads, the E-Z Sonic inserts in E-Z Lok’s threaded insert assortment kits can be installed via ultrasonic horn or heat driver.

-

Press-Side TCUs and Full-Plant Adiabatic Coolers

NPE2024: Frigel North America will launch RSY Syncro and RS/MD series, as well as new innovations in at-the-press and whole plant cooling.

-

Can Plastic Recyclates be Welded Ultrasonically?

What is possible with ultrasound? Will the result with recycled plastics material actually be worse than with standard material? Do we have to adapt our technology?