Covestro Provides Signify with Materials for 3D-Printed Luminaires

Covestro's polycarbonate used for this project fulfills customer requirements such as high impact and heat resistance, freedom of design, optical transparency and flame retardancy, and is completely recyclable.

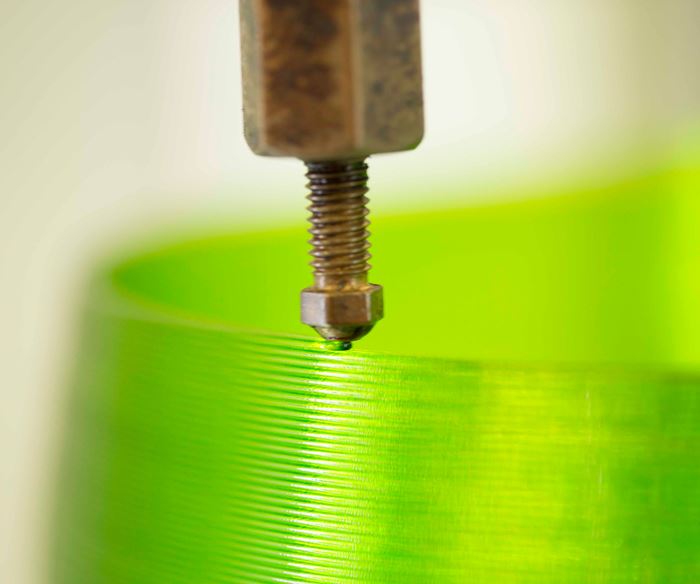

Covestro is providing Signify, a provider in lighting, with polycarbonate for 3D printing luminaires. Signify is expanding its printing capabilities in the Netherlands and plans to establish new facilities in the U.S., India and Indonesia.

Signify chose polycarbonate from Covestro, as it reportedly fulfills customer requirements like high impact and heat resistance, design freedom, transparency and flame-retardance, which allows luminaires to be quickly designed and tailored to customers’ exact needs. In addition, it is 100% recyclable and Signify says it 3D-printed luminaires are designed for a circular economy as nearly every component may be reused or recycled.

“We are the first lighting manufacturer to produce 3D-printed luminaires on an industrial scale. This reinforces our position at the forefront of lighting and sustainable innovation,” said Coen Liedenbaum, venture manager 3D printing at Signify. “Customers are able to bring their ideas to life in a matter of days rather than months, and printing uses less energy.” The company is providing printed luminaires to multiple major retailers.

Covestro regards the circular economy as a key topic and has launched a long-term strategy program for this purpose. “Our company wants to shape the transition from a disposable economy to a circular economy with as many partners as possible,” said Rainer Rettig, head of the circular economy program at Covestro. “To this end, we already provide our customers with tailor-made products today. This project is a wonderful example for this.”

Covestro is currently researching materials to enable an extended range of industrial applications. The company is upgrading laboratories for 3D printing at its Leverkusen, Pittsburgh and Shanghai sites, where it develops and tests material solutions for serial additive manufacturing in collaboration with different customers.

“Covestro offers a comprehensive range of polymeric materials for all common 3D printing methods, including polycarbonate raw materials for this promising application,” said Patrick Rosso, global head of additive manufacturing. “By partnering with companies like Signify, we are pushing existing scale boundaries and supporting various industries along the value chain on their way to digital mass production.”

Related Content

-

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

-

New Tool Steel Qualified for Additive Manufactured Molds and Dies

Next Chapter Manufacturing says HTC-45 — an optimized H-13 — will offer superior thermal transfer and longer tool life.

-

Medical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.

.png;maxWidth=970;quality=90)