Eastman Highlights Circular Economy and Other Areas as Drivers of Growth

Eastman expects to announce at least one additional circular economy project in the first half of 2022.

During its virtual and in-person 2021 Innovation Day on Dec. 7, Eastman Chemical highlighted areas that will help deliver growth through 2024. The circular economy was especially highlighted as a key opportunity.

Earlier this year, Eastman announced that it is moving forward with its circular economy project in Kingsport, Tenn., which includes construction of the world's largest polyester material recycling facility and a Tritan polyester polymerization plant. The project is expected to begin producing at commercial quantities in 2023.

“Over the past several years, we have executed a strategy to position Eastman as a leading material innovation company. Central to our strategy is our compelling, innovation-driven growth model, which is succeeding in creating consistent, sustainable value for all our stakeholders," said Mark Costa, board chair and chief executive officer. "We are leveraging our unique model to create value from disruptive macro trends, which we expect to be a strong contributor to Eastman's growth over the next three years."

Costa continued, "One area in particular that we are very excited about is our leadership position in the circular economy. Through our competitively advantaged molecular recycling capabilities, we are providing solutions for the plastic waste and climate crises while also creating a new vector of growth that has the potential to deliver greater than $450 million of adjusted EBITDA by 2026."

Steve Crawford, executive vice president, technology and chief sustainability officer, discussed how Eastman is leveraging its growth model to accelerate and deliver sustainable innovations and create a competitive advantage.

"The triple challenge created by the climate, plastic waste, and growing population crises has intensified the need for sustainable innovations. To address these issues, we have aligned our top innovation platforms with these significant sustainability drivers," Crawford said. "We are contributing to solutions that build a better world and building a strong pipeline of growth for Eastman that is on track for new business revenue from innovation approaching $700 million in 2024."

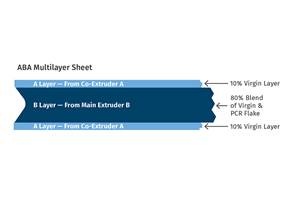

Crawford further detailed the advantages to Eastman's molecular recycling technologies, including a lower carbon footprint, the ability to recycle hard-to-recycle waste, no compromise in performance, and security of supply. He discussed how the circular economy is also creating new growth opportunities for Eastman's biodegradable cellulosic polymers.

Outlining how Eastman intends to achieve its aggressive climate goals, Crawford detailed the company's action plans for reducing its carbon footprint by 2030 and achieving carbon neutrality by 2050.

Brad Lich, executive vice president and chief commercial officer, said the company is in active discussions for additional projects in Europe and the U.S. and expects to announce at least one additional circular economy project in the first half of 2022.

Many brand owners have commitments to increase the amount of recycled content in packaging and products by 2025, which creates a significant imbalance in supply and demand.

“There is no way mechanical (recycling) alone can deliver on that,” Lich said. “So we are going to need multiple technologies. Our first plant really allows us to help show what’s possible in way of circularity. With three world scale plants, it starts to be significant and becomes real to consumers. I think we’re past the time people are interested in hearing about this pilot plant or that pilot plant— they want to see progress now and with three plants, we can deliver progress now.”

On Dec. 7, Eastman hosted its virtual and in-person 2021 Innovation Day. Photo Credit: Eastman

Related Content

Thermoforming PCR: An Equipment Supplier’s Pointers

Thermoforming PCR is not radically different from forming virgin, but variation in recycled materials can require extra care to get a consistent end result. Start by examining every aspect of the process from the sheet (and extrusion process if run inline) to the final trim.

Read MoreRecycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

Read MoreEvolving Opportunities for Ambitious Plastics Recycler

St. Joseph Plastics grew from a simple grinding operation and now pursues growing markets in recycled PP, food-grade recycled materials, and customized post-industrial and post-consumer compounds.

Read MoreHonda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.

Read MoreRead Next

Stanley Black & Decker to Use Eastman's Tritan Renew for Power Tools

With 50% certified recycled content in the enclosures, the Black+Decker reviva line will launch in early 2022.

Read MoreEastman to Build World-Scale Plastic-to-Plastic Molecular Recycling Facility

With this significant investment, Eastman will use its methanolysis process to convert more than 250 million lb/yr of polyester-based waste into high-performance copolyesters.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More