Extruder Builder ENTEK Starts Wear-Parts Division

Division will make replacement wear parts for all twin-screw extruder brands. Tammy Straw named director.

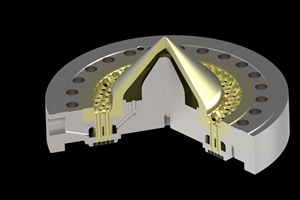

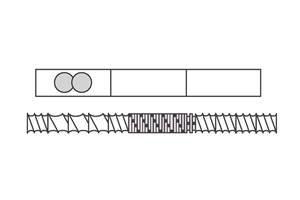

ENTEK Manufacturing has formed a new business unit that will make and sell replacement wear parts (screws, barrels, etc.) for all brands of twin-screw extruders.

“This is an important step for ENTEK, and for twin-screw extruder users worldwide,” said Kim Medford, president of ENTEK Manufacturing. “ENTEK understands this market, and we plan to become the number one manufacturer and supplier of replacement wear parts in the industry.”

ENTEK has named Tammy Straw as director of the new ENTEK Wear Parts Division. In her new role she will have profit and loss responsibility for the division and will report to Linda Campbell, v.p. extrusion sales for ENTEK Manufacturing. A 24-year ENTEK employee, Straw has been the company’s marketing & business development manager since 2016, where she also led ENTEK’s inside sales team.

Tammy Straw. Photos: ENTEK

Also joining the Wear Parts Division is Kelsey Dennis, who will be responsible for Wear Parts Sales. Kelsey has been with ENTEK since 2010, and most recently worked in customer support and inside sales.

“I’ve worked closely with Tammy for the past 24 years and can say with confidence that she is the best person to manage this new division of our company,” said Campbell. “No one has more experience with managing wear parts needs for our customers. And Kelsey being our new wear parts salesperson is also great news for our customers. She is passionate about providing excellent service and has been working directly with customers since she joined ENTEK.”

All In on Wear Parts Production

At a press event in February at its new facility in Henderson, Nev., ENTEK announced that it had invested $15 million and was hiring more than 100 new employees to staff the new facility, which would be used for increased production of wear parts, twin-screw extruders, and material handling equipment. Now that the new manufacturing facility is up and running, the company has created a new stand-alone division solely dedicated to replacement wear parts.

Kelsey Dennis

“We have built replacement wear parts for both ENTEK and other-than-ENTEK twin-screw extruders for many years now,” said Campbell. “But we recognized the need to devote more resources to this part of our business. ENTEK has always been a company that grows by listening to the needs of our customers. And what we learned was, the industry needs a U.S.-based parts supplier that truly understands twin screw wear parts and offers tailored made purchasing packages.

“We intend to support growth with our existing customers, while aggressively expanding our parts business.”

Industry Best Lead Times

Straw said that a big part of ENTEK’s value proposition to customers is the ability to provide fast delivery of wear parts. “Even though the global supply chain disruptions have eased a bit recently, it’s not unusual for companies to have to wait 4-6 months or more for replacement screws and barrels,” she said. “ENTEK knows as well as anyone that these are unacceptable lead times and we are committed to changing that, in a big way.”

The Henderson facility currently has two shifts fully staffed and operating, she said. “We are currently making screw inventory and are stocking many sizes for both ENTEK and other-than-ENTEK twin-screw extruders. Our lead times are four weeks if not on the shelf, and we are on our way to two-week lead times for new screw production.”

The new division is actively seeking other OEM parts business, she said. “We are offering the highest quality replacement parts in the industry, manufactured here in the USA, for all OEM sizes and models,” she said. “We encourage all twin-screw extruder owners to reach out to us for their replacement wear parts needs.”

Related Content

Improving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

Read MoreLFT-D Thrives in Automotive and Other Durables

Teijin Automotive acquires its 10th direct long-fiber thermoplastic system as demand for this technology soars.

Read MoreHow to Maintain Pelletizing Quality When Acid Attacks

Developments in the chemistry of polymers and additives have made corrosion a real problem in pelletizers. Here’s how to ward it off.

Read MoreConfiguring the Twin Screw Extruder: Part 4

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More