Machine Monitoring System Adds ‘Hands-Free’ Downtime Analysis

Get automated analysis of downtime amounts and reasons without any operator input.

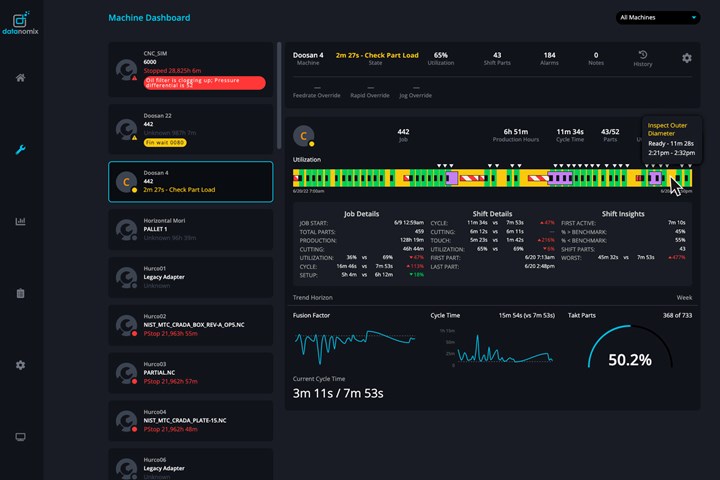

Datanomix of Nashua, N.H. (datanomix.io), has added a new feature, Automated Downtime Insights, to its “hands-free” machine-monitoring program. This capability delivers automated analysis (such as Pareto charts) of the frequency of different types of stoppages—loading/unloading of parts, dimensional checks, tool changes, routine maintenance or unscheduled downtime—all without requiring any operator input of reason codes. According to Datanomix, this hands-free feature helps remedy lack of information on downtime due to labor shortages, lack of operator training, or inadequate utility of downtime codes.

Datanomix has been in business since 2017 and so far has served mainly CNC machining of metals and plastics, though Greg McHale, cofounder and chief technology officer, says the company is seeking customers in plastics molding, too. The Datanomix system connects to the machine controller or sensors on the machine through standard protocols such as MTConnect, OPC-UA and IO-Link. The system stores data in the cloud and provides a standardized dashboard that automates machine and job performance analysis in real time and over time. It reports performance indicators such as machine utilization, cycle efficiency and production totals—all with no configuration. “Customers want something that just works right out of the box,” says McHale. He adds that installation by Datanomix technicians on-site commonly gets the system up and running within 24 to 48 hr. ROI is typically less than one month, he says.

The Datanomix system is supplied on an annual subscription basis, which minimizes upfront investment and guarantees automatic updates. Annual subscription cost for a typical plant with 10 to 20 machines is in the range of $15,000 to $25,000.

Related Content

-

AI-Based Injection Molding Assistant Launched

LS Mtron’s new AI Molding Assistant and Smart Weight Control technologies can help molders reduce costs while achieving higher quality and productivity.

-

What Comes After MES? It’s Already Here

If you’re not sure what the initials M-E-S mean, or whether that’s something your business needs, it may be time to look beyond MES to the next generation of manufacturing connectivity.

-

An Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.

(2).jpg;maxWidth=970;quality=90)

(2).jpg;maxWidth=300;quality=90)

(1).jpg;maxWidth=970;quality=90)