Polyplastics’ Design Techniques on How to Reduce Noise in POM Helical Gears

Based on design findings, Polyplastics offers its know-how on noise reduction of gears made with its Duracon POM.

A range of design tips and know-how that can help manufacturers reduce noise of helical gears made of polyoxymethylene (POM) is being offered by Japan’s Polyplastics (U.S. office in Farmington Hills, Mich.) The company is a leading global POM producer sold under the Duracon tradename for diverse markets including gears.

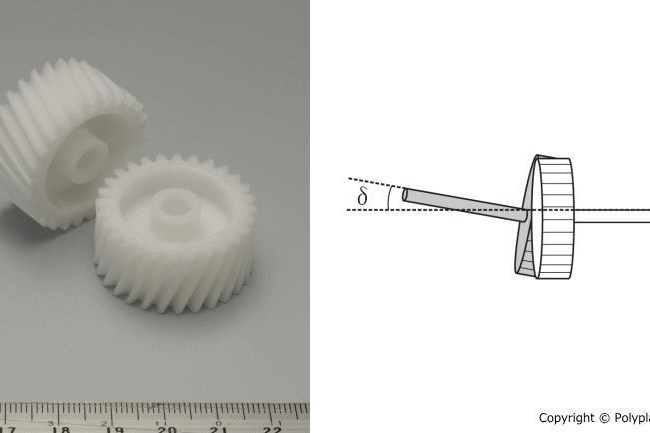

Among the design findings is a debunking of the the general belief that the tilt of the gear axis is an important consideration and its elimination will have a positive impact on noise issues. Polyplastics tried to verify that assumption, and actually focused on the skewed shaft angle (offset error). The company learned that noise does not necessarily worsen when the axis tilts.

Instead, Polyplastics found that noise issues arise when changing the center distance, depending on whether there is a skewed shaft angle. The company examined the impact of center distance for helical gears with a skewed shaft angle of 0 deg. Noise levels are lowest in the area where an increase in center distance is between 0 and 0.6mm, and then flattens out. On the other hand, noise increases beyond 0.6mm because the transverse contact ratio is less than 1.0.

Polyplastics notes that helical gears have a phenomenon called overlap ratio. Total contact ratio is the sum of transverse contact ratio and overlap ratio, and theoretically total contact ratio must be 1.0 or higher for rotation at constant speed on the driven side. Transverse contact ratio less than 1 means that the length of path of contact is less than one pitch. In other words, there is a space in which teeth do not touch within the space of one pitch. Findings show that helical gears will have a total contact ratio of 1 or higher and will keep operating at constant speed without noise issues.

Related Content

-

Resins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

-

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

-

The Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.