The Role Barrel Temperatures Play in Melting

You need to understand the basics of how plastic melts in an extruder to properly set your process and troubleshoot any issues. Hint: it’s not about the barrel temperature settings.

If you don’t understand how a screw melts plastic, it will be hard to resolve many daily processing problems in extrusion. For example, I was recently asked by a large processor to help them determine the ideal barrel temperature settings for each of eight different HDPEs from eight different suppliers so they could process each of them with similar results.

Interestingly, this inquiry was from a successful processing company that’s been in business for many years. They were looking to improve their purchasing leverage with a seamless effect on manufacturing efficiency part quality. They thought they could achieve those objectives by maintaining a constant melt temperature.

What they didn’t realize was that the process to make HDPEs has many variables and uses many different chemicals besides ethylene. Naturally, the different processes and variety of chemicals used have some effect on the polymer and resultant processing results. The slightest variation in any of the chemicals, either in amount or purity, for either process can change the molecular weight, its distribution and uniformity.

Melting is controlled by the screw rotating in the barrel which creates shear stress in the contained polymer.

There are also many possible variations within the process, with literally dozens of temperature and pressure settings through the polymerization step, as well as things that vary widely, such as catalyst removal. Additionally, there are various additives such as waxes, antioxidants, stabilizers and more that are added that can also vary the processability of the polymer. Also, any variation to the final specifications is often overcome by postprocess blending. Therefore, to expect to be able to process many different HDPEs at the same melt temperature is highly unlikely.

It seemed like their inquiry assumed all HDPEs were essentially identical in their molecular structure and therefore very small changes in barrel temperatures would homogenize those minor differences. Nothing could be further from the truth. The barrel temperatures actually have very little to do with the final melt temperature.

A classic illustration of this is when you see a processor running HDPE with all the zones set for full cooling (for example, no barrel heating) and still producing a complete melt-usable melt temperature. And my own experience is typical of HDPE processing. So where is the heat coming from if not from the barrel heaters?

This particular processor believed most of the heat came from the barrel heaters. Actually, the barrel heaters are primarily for startup and have minimal effect on melting and the resultant melt temperature with the exception of very small extruders (less than 1 inch). Melting is controlled by the screw rotating in the barrel which creates shear stress in the contained polymer. The polymer sticks against both the heated screw and barrel surfaces. As the screw rotates relative to the barrel, the polymer between them is stretched or “sheared.”

The energy to rotate the screw comes from the screw drive. The torque of the screw drive is converted to thermal energy (heat) from the shear stress exerted on the polymer, which shows up as the melt temperature accounting for almost all the heating during processing. The shear stress is maximum at the barrel wall and near zero at the screw root. As the melt forms at the barrel inner surface, a well understood melting pattern develops, which we will not discuss hereFor reference, I recommend Engineering Principles of Plasticating Extrusion, by Zehev Tadmor and Imrich Klein. I studied extensively with Klein in the late 60s and still refer to many of his concepts and calculations.

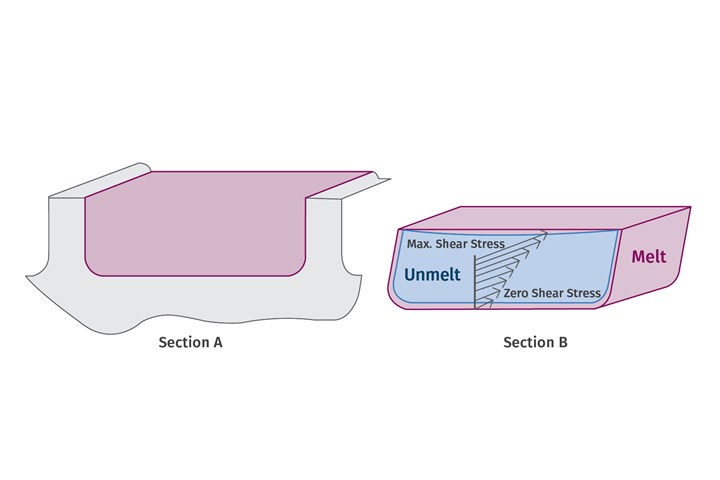

In the accompanying figure, Section A shows the screw channel filled with polymer. Section B shows a cross section of just the polymer in the channel and the shear stress applied to the polymer due to screw rotation with the maximum shear stress at the barrel wall and the minimum at the screw root diameter. The shear stress at the barrel wall is directly proportional to the relative motion of the barrel to the screw.

Section A shows a screw channel filled with unmelted polymer. Section B shows the polymer in the channel before any screw rotation, then the effect of shear stress. Source: J. Frankland

If barrel heating supplied most of the energy for melting, you would be able to start up almost immediately after turning on the barrel heaters. However, it typically takes several hours for the polymer in the screw to be sufficiently heated or melted to start screw rotation. That’s because polymers are excellent insulators and do not conduct heat readily, while the barrel heats quickly due to the high thermal conductivity of steel. Shear heating is much more effective for melting because it utilizes the polymer’s own viscosity to accomplish the energy conversion. Therefore, the amount of melting is mainly a function of the screw design, polymer viscosity, polymer-specific heat and other parameters such as crystallinity. As a result, to change the melting rate, the screw design must be changed.

If barrel heating supplied most of the energy for melting, you would be able to start up almost immediately after turning on the barrel heaters.

Screw design determines the melting rate and eventual melt temperature at any specific discharge pressure and screw speed for a given polymer. Rather than the barrel heaters being used to adjust melt temperature, the head pressure is usually a much more efficient way to adjust melt temperature. An adjustable flow restriction valve after the extruder enables a change in head pressure or a resistance to the screw output and is a much more effective device than barrel heat for changing the melt temperature. By raising or lowering the head pressure, the output of the screw at the same screw speed is altered, changing the torque of the screw drive and the resultant heat transfer to the polymer. Alternatively, to change the melting and melt temperature, the screw design must be changed, everything else remaining the same.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 45 years. He is now president of Frankland Plastics Consulting LLC. Contact jim.frankland@comcast.net or 724-651-9196.

Related Content

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreHow Much L/D Do You Really Need?

Just like selecting the extruder size and drive combination, the L/D should be carefully evaluated.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More.jpg;width=70;height=70;mode=crop)