Stratasys Announces Winners of the CoVent-19 Challenge to Design New Ventilator

The three winners will receive a total of $10,000 in credits for 3D printing from Stratasys.

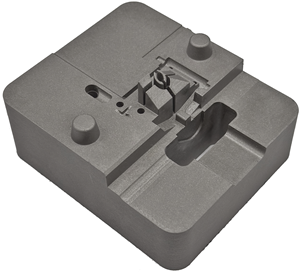

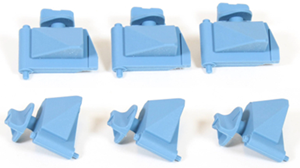

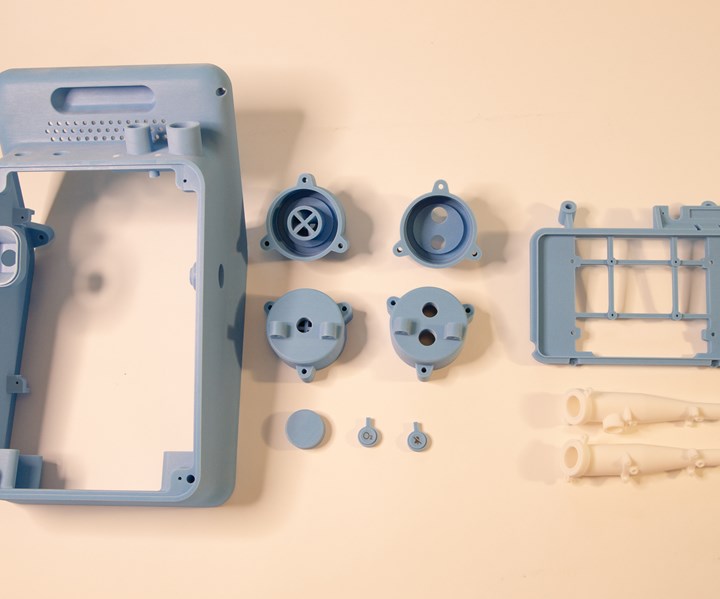

InVent Pneumatic Ventilator prototype parts from a Stratasys J850 3D printer.

In April, I reported that a dozen anesthesiology resident physicians from Massachusetts General Hospital kicked off a public challenge to design a rapidly deployable, minimum viable ventilator that could address shortages caused by the COVID-19 pandemic, particularly in developing countries.

Well, now, three months and more than 200 submissions later, a team of engineering alumnae, staff and faculty from Smith College in Northampton, Mass., had taken a winning design from concept through working prototype. The next step could be a final product for regulatory approval in Nigeria, which is one of the countries that have been talking with the CoVent-19 Challenge organizers.

The 30-person Smith College team collaborated on a simplified, cost-effective, easily manufactured pneumatic design particularly tailored to COVID-19 patient needs. The SmithVent design, which is said to be one-tenth the cost of traditional ventilators, combines economical proportional solenoid valve technology with an air-oxygen mixing chamber to meet the full set of requirements for COVID-19 ventilation. The team relied primarily on readily available, off-the-shelf components, which reduced custom machining and improved compatibility with other medical equipment. The enclosure, ISO fittings, and mounting blocks can be produced using FDM or stereolithography 3D printers. The design is open source for anyone to use and improve.

Two other teams were also recognized by the CoVent-19 Challenge judges. The second-place InVent Pneumatic Ventilator was submitted by a San Francisco-based team comprised of fuseproject, a design and innovation firm founded by Swiss designer Yves Behar, and Cionic, a medical device technology start-up. The InVent prototype is a pneumatically driven ventilator optimized for a COVID-19 healthcare context that can be assembled in under four hours. The prototype used 3D printing technology from Stratasys, and featured a simple and intuitive human-machine interface and custom rapid-manufactured venturi flow sensors. A multi-ventilator tablet display encourages patient distancing.

The third-place prototype, RespiraWorks, was developed by a global team of dozens of engineers, healthcare workers, and other professionals that bring a focus on developing countries and low-resource communities. The model uses a sophisticated blower-based ventilation system, simplified assembly and manufacturing, and high-quality, open-source software. Parts are designed to be available from local supply chains around the world.

Dr. Richard Boyer, founder and director of the CoVent-19 Challenge, said when they began planning in March, it was unclear if there would be enough ventilators even in the U.S. to treat pandemic patients. “Our focus has since shifted to developing countries, where we’re seeing high death rates and limited resources to deal with the ravages of this new disease,” he said. “The test bed we developed gives us a lot of confidence in the performance of the winning prototype, and frankly there is probably tremendous value in getting other finalist designs out into the world too.”

Seven finalist prototypes were evaluated using a test bed to determine which design provides the best combination performance against safety, reliability, manufacturability, affordability, and simplicity.

The three winners will receive a total of $10,000 in credits for 3D printing from Stratasys, which also provided access to free 3D printing and a team of three application engineers for the seven finalist teams building their working prototypes.

Related Content

Production Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

Read MoreFreeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

Read MoreBusiness Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

Read MoreHow Additive Manufacturing Can Help, not Hinder, Injection Moldability of New Designs

Four cost drivers—design for moldability, mold-base size, internal componentry, polish/custom finishing—dictate the financial and processing success of a molded part design. Learn how 3D printing can assist this process, while also understanding its potential pitfalls.

Read MoreRead Next

Stratasys Coalition Expands to Ramp Up Face Shield Production With 3D Printing

Stratasys has received requests for 350,000 face shields, so further acceleration in production across coalition members is critical.

Read MoreCoVent-19 Challenge Asks Designers and Engineers to Respond to the Ventilator Crisis

This global, open innovation initiative is via Stratasys GrabCAD platform and designed to help develop a rapidly deployable mechanical ventilator.

Read MoreAmerican Manufacturing Steps Up to the Coronavirus Challenge

Plastics processors are among the manufacturers that stepped up big-time in the face of the global COVID-19 pandemic. I’m proud to turn over this space this month to Rick Kline Jr., president of our parent company Gardner Business Media, whose comments below (edited) appeared originally March 31 in a OpEd piece published by the Wall Street Journal.

Read More