Artificial Intelligence Manages Changing Conveying Conditions

NPE2024: Billed as an industry first, controls autonomously adjusts the conveying system in real-time to move material under optimal conditions.

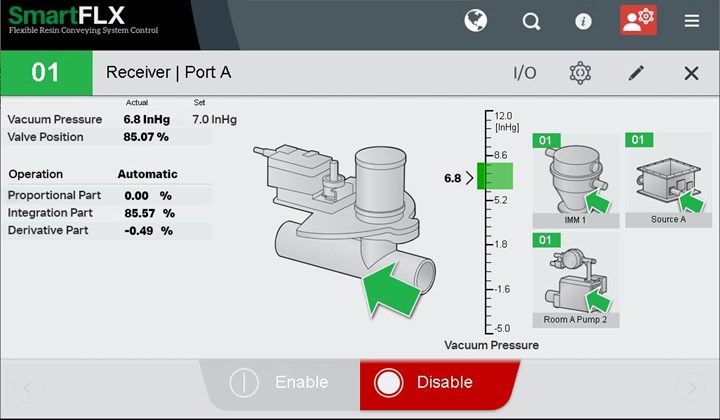

Conveying with Optimizer from Conair is a patented artificial intelligence (AI)-driven feature for material handling systems using the Conair SmartFLX conveying control. Now, a SmartFLX conveying control equipped with the Optimizer package automatically detects source-to-destination conditions (vacuum, receiver distance, material bulk density and other factors) then autonomously adjusts the conveying system in real-time to move material under optimal conditions.

The autonomous capabilities of the Conveying with Optimizer feature were designed to overcome the trickiest, most labor-intensive part of conveying operations: the need to manually adjust air and material ratios (using manual air valves) from source to destination. In practical terms, that means operators must constantly change settings on distribution boxes, pick-up boxes or gaylord wands to move material amid constantly changing system conditions.

When systems are properly tuned and when operators guesstimate right, material usually moves predictably. But an incorrect manual adjustment or any number of other changes — conveying distance, material bulk density/regrind ratio, relocated equipment, or even a minor vacuum leak caused by a hose or coupling — can spell conveying problems that result in downtime: empty receivers, clogged lines, overloaded pumps, resin losses, or excessive system wear.

The artificial intelligence built into Conveying with Optimizer replaces error-prone human decisions, instead making autonomous system adjustments that move material while compensating for typical conveying system faults. The Optimizer package combines novel software, hardware, sensors, and intelligence with the high-speed computing power of the SmartFLX control. Together, these elements sense, calculate, and compensate for changing conditions far faster than a human could, while ensuring optimal air/material ratios and trouble-free conveying. And, the machine learning capability of the Optimizer feature enables it to continually refine and perfect each conveying cycle over time.

So, it’s no longer necessary for a processor to pay an operator to walk to the material distribution box, make a feed-tube adjustment, and then walk to the conveying control to issue a command. Now, the operator simply enters the command — locally on the SmartFLX control or remotely via Conair SmartServices on a connected device – and leaves the Conveying with Optimizer intelligence to figure it out and complete the conveying cycle.

The only prerequisite for Conveying with Optimizer is a conveying system equipped with a SmartFLX control. The Optimizer package may be ordered with a SmartFLX control from the factory or installed to an existing SmartFLX control in the field. Optimizer hardware, which is available in line sizes from 1.5 to 4 inches OD, is installed at material pick-up points, while Optimizer software upgrade is loaded into the SmartFLX control.

Related Content

-

Conair Names New Execs in Sales, Systems, Product Management and Extrusion

Moves aimed at strengthening customer focus, market awareness, and technical expertise in key areas of our business.

-

‘Digitalization’ – Awkward Term for a Vital Concept

At K 2022, 85 machines from 40 companies showed off their Industry 4.0 capabilities via OPC-UA interface. A new universal interface for Material Supply Systems was revealed at the show.

-

Central Controller, Energy-Efficient Pump for Conveying

Wittmann debuts new control system and pump at Fakuma.