Conair

200 W Kensinger Dr.

Cranberry Township, PA 16066 US

800-654-6661 | 724-584-5500

conairgroup.com

About Conair

Conair is a global leading supplier of auxiliary plastic process equipment and solutions for plastics processors.

IS THIS YOUR COMPANY?

Video Gallery

Stressed Over a Major Plastics Facility Expansion or a New Project? Conair can help.

MAPP Webinar from 2-22-24. Why take your new system expansion project or greenfield to Conair? Because they have the ...

Catheter Taper Tube Extrusion Demonstration setup at MD&M West 2024 - 4K time lapse

Setup time lapse of Conair booth 4111 at MD&M West 2024 (IME West). This medical extrusion line is producing taper tube, ...

Medical taper tube extrusion line for MD&M West 2024 - Pre-show teaser

In this pre-show teaser, we show how Conair's downstream and upstream equipment (material handling equipment including ...

Conair Gravimetric Extrusion Control for Pipe and Tubing Production

This recording of the Plastics Technology webinar from October 30, 2023, is Alan Landers presenting about the Conair ...

As Seen On Plastics Technology

Conair Supplies the Following Products

- Automation/Systems Integration

- Blenders (non-intensive)

- Chillers

- Conveying Equipment (pneumatic and Mechanical)

- Conveyors (parts-handling)

- Cooling Towers

- Cutoff Equipment

- Desiccant for Dryers

- Dewpoint Monitors/Moisture Analyzers

- Dryers for Resins

- Dust Removal Equipment

- Feeders

- Film Take-off Systems

- Granulators

- Heat-recovery Systems

- Hopper Loaders

- Hoppers, Bins, Tanks

- Hot-water or Oil-circulating Temperature Controllers

- Knives for Granulators, Pelletizers

- Metal Detectors, Separators

- Metering, Proportioning Equipment

- Mold Dehumidification Systems

- Pipe Take-off Systems

- Profiles, Tubing, Hose Take-off Systems

- Pulverizers

- Pumps - Liquid Additive

- Saws

- Scrap-reclaim Systems

- Semi-bulk Containers

- Shredders, Guillotines

- Silos

- Training Programs in Plastics

- Tumblers

- Vacuum Pumps

- Valves, Gates, Diverters

- Water Treatment/Filtration Systems

Editorial, News, and Products

-

Precise Blender for Low-Throughput Molders

NPE2024: Gravimetric batch blender precisely delivers precise material blends from up to four ingredients at extremely low throughputs.

-

Downstream Line for High-Precision Profiles

NPE2024: System features calibration and cooling tables, haul-offs, cutting units and tilting tables.

-

Smart Granulator Control Integrates Size-Reduction Systems, Enables Predictive and Knife Maintenance

NPE 2024: Conair’s New SG Control is available for its Viper Granulators

-

Conair: Going All In on AI

A dozen new products debut at NPE, but the company says new AI-based conveying technology is the true game changer.

-

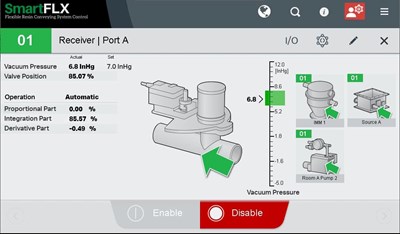

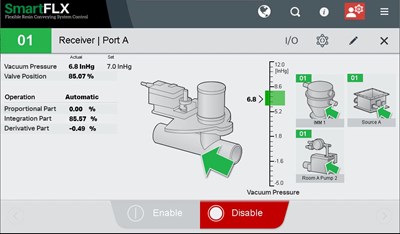

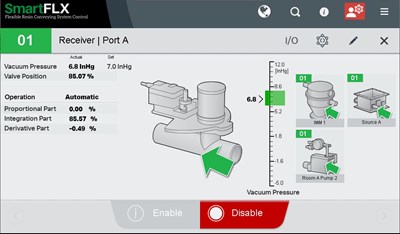

Artificial Intelligence Manages Changing Conveying Conditions

NPE2024: Billed as an industry first, controls autonomously adjusts the conveying system in real-time to move material under optimal conditions.

-

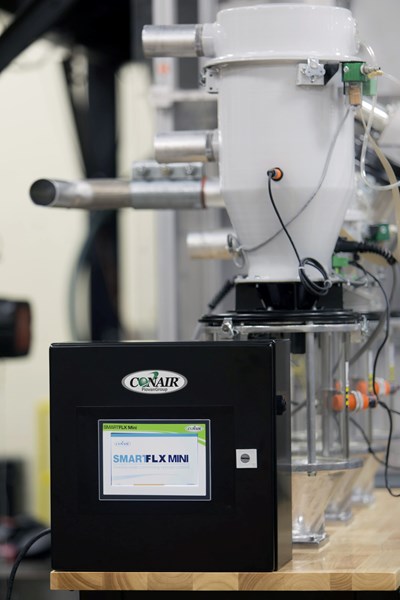

Mini Control Offers Central Conveying for Small Plants, Work Cells

NPE2024: System supports vacuum conveying systems with up to three vacuum pumps and a maximum of up to 12 receivers.

-

Resin-Selection Station Conveys Material on Demand

NPE2024: Powerful, space- and labor-saving station makes the connections and conveys material automatically on command.

-

AI Manages Resin Drying Airflows and Throughputs for Energy Savings

NPE2024: Optional feature automates the process of maintaining process-ready resins at perfect temperatures and varied throughputs, while preventing overdrying and realizing significant energy savings.

-

Resin Drying Hoppers Offer More Energy Efficiency, Durability and Cleanability

NPE2024: Drying hoppers provide improved energy efficiency and a durable textured metal exterior finish. Thicker insulation provides a cooler working environment, while polished stainless steel interiors resist material entrapment, and make cleanouts and changeovers faster.

-

Conveying System is AI-Driven

NPE2024: New system creates and maintains optimal source-to-destination material flows.

-

Recycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

-

How to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

-

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling strives to recycle ALL of it.

-

Conair Names New Execs in Sales, Systems, Product Management and Extrusion

Moves aimed at strengthening customer focus, market awareness, and technical expertise in key areas of our business.

-

Conair Group PTXPO Spotlight

Conair discusses the upcoming Plastics Technology Expo (PTXPO) March 28-30

-

New Shredders Offer Size Reduction in a Small Footprint

Conair has introduced its GP series shredders for processors who need to reduce hard scrap too large for a granulator, but do not need the high throughput or cost of a larger shredding machine.

-

Troubleshooting Leaky Temperature-Control Units

Learn the causes, symptoms and remedies for TCU leaks to keep these vital contributors to plastics processing up and running longer and more efficiently.

-

Avoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

-

Haul-Offs Offer Heavy-Duty Pulling for Pipe

The new PipeMaster MBC Series Pipe Haul-Offs from Conair offers durable, powerful pulling solutions for PVC and polyolefin pipe extrusion lines, with six models sized to handle pipe from 2.5 in. (63 mm) to 24.9 in. (630 mm) in diameter.

-

Moisture Monitor Provides Instant Readings to Confirm Drying Efficacy

Real-time monitor measures material moisture continually and set points can be configured so that an alert is issued when the specified moisture level drifts outside prescribed limits.

-

Redesigned TCU Line Expanded

Conair’s TW-E and TW-B Series feature upgraded mechanical and electronic components for improved durability and control, plus a new panel layout that improves airflow and cooling.

-

How Machine Monitoring Delivers Tangible Results

Much more has been said than done about reaping the benefits of data driven manufacturing among plastics processors. Good technology is essential, but change management is the most difficult part of the process. Here’s how to think about both.

-

Tank Offers High-Capacity Cooling for Pipe

Suited for extruded PVC and polyolefin plastic pipe up to 24.9 in. in size.

-

Suppliers Team to Run Tubing, 3D Filament at Medical Show

At MD&M/Plastec West show in Anaheim, Conair to run extrusion line with technology partners Davis Standard and Zumbach Electronics.

-

Injection Molding Live Demos to Highlight First-Ever PTXPO

Major suppliers will be running injection machines in the first plastics industry trade show in the Chicago area since 2009.

-

New President for Conair Group

Auxiliary equipment builder names Jason Ganim president.

-

Fluff Feeder Offers Higher Film-Scrap Capacity, Better Reclaim Efficiency

Feeds granulated film scrap into a stream of virgin material and delivers the mix to extruder.

-

System Protects Resin from High-Speed Conveying

Processors can easily and automatically select and use capabilities to protect resins from damage caused by dilute-phase conveying systems operating at excessive speeds.

-

Follow These Seven Management Tips for More Consistent Resin Drying

Equipment and advice sure help, but ultimately, good management makes the difference.

-

System Targets Large-Diameter Pipe

Downstream line is packaged with mono- or multi-layer die for PVC or polyolefin pipe up to nearly 25-in. diam.

-

Temperature Control Units Updated

Included in the new Thermalotor TCUs from Conair are the first units available with the company’s new “common control”—a company wide initiative to standardize HMIs.

-

New Packaged Chiller Line

Conair’s new ECO air-cooled chillers provide processors wide ambient operating conditions and a broad operating setpoint range.

-

In-Line Proofing System for Resin Distribution

Wireless RFID system said to simplify and error-proof resin distribution.

-

Mini Deduster Redesigned, Simplified

Moving parts eliminated, built-in level sensor added.

-

Expanding Profile Extrusion Capacity? Might Be Time to 'Go Dual'

Demand for building products is thriving, and profile extrusion houses are looking to expand capacity. The question they—and possibly you—face is to simply add more single-profile lines or “go dual.” Here’s what you need to consider.

-

Conveying Control Offers Auto-Configuration, Cost-Saving Diagnostics

New features said to simplify and reduce costs for system design and installation, system expansion, and remote diagnostics

-

Conair Parent Buys Conveying Systems Firm

IPEG purchases long-time partner company Phoenix Systems, which makes powder and pellet conveying and unloading equipment used by processors in high-volume applications.

-

Process Cooling: Portable Chillers Add PLC Control, Color Touch Screen

Conair says a PLC control and a 7-inch, color touch screen are now standard on its EP2 Series of portable chillers.

-

Auxiliaries: Sensor Kits Enable Non-Computer-Controlled Auxiliaries to Connect to Cloud Platform

User-installed sensor kits are now available for use not only with Conair auxiliaries on the SmartServices platform, but with a range of competitive auxiliary equipment.

-

Extrusion: Coil-Strapping System Protects Tubing, Simplifies Handling

Unit automatically and securely straps finished coils of small-diameter extruded tubing.

-

Recycled Resin Gains Molder a Green Niche

Injection molder AGS Technology uses compounding know-how to turn old scrap into new auto parts that satisfy performance and sustainability goals.

-

Making the Cut: Pick the Right Cutting Technology for Pipe, Tube or Profile

Here is review of popular extrusion cutting technologies, strengths and limitations of each, and common problems and solutions.

-

Conveying: Pump is Quiet, Powerful, Energy-Efficient

The multi-stage regenerative impeller design of the new Conair HRG Series vacuum pumps is the key to developing deep vacuum power for conveying plastic pellets over long distances, while keeping noise levels comfortably low.

-

How to Blend More Accurately with Gravimetric Blenders

With intelligent and adaptive control technology combined with precision hardware, today’s best gravimetric blenders can deliver previously unachievable levels of accuracy. You’ll see the difference in more consistent injection molded or extruded product and reduced colorant and additive waste.

-

Act Sooner, Not Later, on Auxiliary Equipment Alarms

There can be real financial, safety, and quality benefits for processors who train plant personnel to interpret and respond promptly to various alarms. Real-world examples offer proof.

-

Conair, Partners Run TPE Tubing, ABS 3D Filament at Medical Show

Conair joins Davis-Standard and Zumbach to demo complete system that switched between tubing and filament runs at Plastec West Show in California.

-

Heating/Cooling: Temperature Control Offers Non-Ferrous Cast-Bronze Construction

For Conair’s Thermolator TCUs that use water as coolant there is now an optional non-ferrous construction for all wetted parts.

-

Former Conair President Kenyon Dies

Served as president and COO of auxiliary equipment supplier for more than 18 years.

-

Resin Drying: Natural Gas Powered Process Heaters Offer Energy Savings

Conair says that with its GasTrac process air heaters, processors can realize energy cost savings of up to 70% by replacing electricity with natural gas as a heat source for dehumidifying dryers.

-

Resin Drying: Central System Offers Individualized Hopper Monitoring, Trending and Control

New system from Conair allows implementation of advanced control features on a per-hopper basis, including on older Conair dryers, as well as some competitive units.

-

Industry 4.0—Auxiliary Equipment Monitoring Platform Expands Capabilities

Conair’s SmartServices platform adds centralized, full-featured machine controls and programmable performance indicators.

-

Feeding: Micro Feeder Allows Pellet-By-Pellet Dosing

TrueFeed Micro Feeder from Conair designed for ultra-low doses—less than five pellets/sec.

-

Drying: Large Dryer Series Simplifies, Makes More Features Standard

All the units in the new D Series of large dryers from Conair will feature desiccant-wheel technology, a common touchscreen control and an expanded set of standard features.

-

How to Avoid Unpleasant Surprises in Size Reduction

Size-reduction equipment doesn’t get much attention unless there’s a problem or an entirely new application challenge. So when it’s time to repair or upgrade, take these steps to avoid any unpleasant surprises.

-

VIDEO: Injection Molding Experts Confront Industry’s Challenges

The technology divide in molding; worst practices; low pay and less training—a panel of injection experts tackled some of the tough issues facing processors today during a panel at Molding 2019.

-

True Portability Comes to Waterless Press-Side Dryers for Injection Molding

Conair’s new line of mobile resin dryers brings a whole new meaning to “portable.” With waterless desiccant drying and conveying combined on a compact, mobile base, these versatile units save on installation costs, utility costs and maintenance.

-

Resin Conveying System Maximizes Throughput While Minimizing Material and Machine Abuse

Patented technology allows plastics processors to convey material at whatever speed provides the best throughput without damaging equipment or resin.

-

How to Maximize Your Conveying System Performance

If your conveying system isn’t up to snuff, and you don’t have the budget to overhaul or expand it, don’t lose hope. There are many factors that could be limiting your conveying performance, and a number of them cost little or nothing to fix.

-

How to Improve Production of Catheters and Stents

Advances in downstream extrusion equipment have boosted production control.

-

NPE2018 Auxiliaries: A Path to Industry 4.0 Emerges

Industry 4.0 dominated the news in auxiliary equipment at the show, but many questions remain for both suppliers and processors.

-

Material Handling: Truck-Fill Line Prevents Silo-Filling Errors

New truck-fill line-proofing system prevents material mix-ups by remotely locking access to silo-fill lines so only the correct line can connect.

-

Material Handling: Manage Bulk-Resin Storage for 30 Silos on One Touchscreen

New Railcar Unloading Controller manages railcar unloading, silo selection, material routing, and silo filling from one control inside the building.

-

Material Handling: Miniature Central Vacuum Loads Up to Eight Machines

Vacuum conveying system combines the powerful vacuum pump, dust collector and PLC-based touchscreen control of a larger system with a compact and portable design.

-

Material Handling: New Loaders and Receivers Handle Smaller Throughputs for Medical Jobs

Cleanroom-ready design and construction make them well suited for medical processing applications on injection molding machines up to 400 tons.

-

Dual-Strand Profile Line Gives Extruder Twice the Output

Steady growth in product demand and a full manufacturing floor required profile extruder Intralox to get creative when it needed to upgrade its equipment.

-

New Program Guarantees Performance of Auxiliary Equipment

Web-based and cloud-powered, Conair’s new SmartServices platform is key to its just-launched ‘Uptime Guaranteed’ initiative.

-

NPE2018 New Technology Focus: Drying

Industry 4.0 meets resin-drying at NPE2018.

-

Conair Applies Industry 4.0 to Make Service Smarter

Web-based and cloud-powered, Conair’s new Industry 4.0 SmartServices platform is key to its just-launched Uptime Guaranteed initiative.

-

Conair Launches New Viper Granulator Product Line

Seven different models are on display at the show, in configurations for injection molding, blow molding and both pipe/profile and film/sheet extrusion.

-

Conair Rolls Out ‘Uptime Guaranteed’ Initiative, Guaranteeing Its Equipment’s Performance

Conair plans to walk the walk when it comes to ensuring the performance of all its equipment via what it calls the deepest service team in the industry and new Industry 4.0 tools.

-

Recycling/Scrap Reclaim at NPE2018: Technology Focuses on Boosting Regrind Consistency, Pellet Quality

There will be no shortage of new technology and highlights of the latest trends in recycling and sustainability at NPE2018.

-

Auxiliaries at NPE2018: Packing More Functions in Less Space

Auxiliary equipment suppliers are building more and more technology into their products, packing more physical and virtual functions into the same or smaller footprints.

-

New Valve Bids to Increase Wave Conveying Capacity

Conair says it has perfected a new automatic-flush common line valve, potentially increasing the overall capacity of its patented Wave Conveying system.

-

New Granulator Product Line From Conair

Seven different models are on display at the show, in configurations for injection molding, blow molding, and both pipe/profile and film/sheet extrusion.

-

NPE Trend Watch: Predictive Maintenance

New technology allows processors to address equipment and component hiccups before they start to foul up manufacturing.

-

Line Redesign Launches New Small- and Mid-Size Desiccant Dryers

After cooling options and a new control highlight completely revamped dryer line.

-

Coextrusion Line Demonstrates Technology for API Catheters

At trade show, suppliers team to show how to run a medical tube that includes medicine.

-

A Culture Built on Innovation in Medical Tubing Extrusion

Microspec was born out of innovation, and 28 years later continues to set the global standard in medical tubing by developing high-precision multi-lumen catheters—among other tubing products—by refusing to believe “it can’t be done.”

-

EXTRUSION: Planetary Cutter Offers More Precision for Medical Tubing

Secondary off-line finishing is said to be all but eliminated.

-

Giant Electric Presses Are Key To Productivity Gains at Subaru

Car builder reaps cycle-time improvements and other benefits with large electric presses.

-

More Examples of Advanced Chilling Technology

Now three chiller makers use variable-speed condensers to save energy.

-

Conair Names Sam Rajkovich V.P., Sales & Marketing

In this role, he'll define and implement short- and long-term programs that build industry awareness.

-

Suppliers Running Precision Fluoropolymer Tubing at Medical Show

Catheter tubing with an x-ray stripe made with contributions from four equipment suppliers.

-

Suppliers Team to Run Precision Teflon Tubing at Medical Show

Apart from the triennial K Show, extrusion system suppliers don’t operate lines at trade fairs that much anymore.

-

VIDEO: Extrusion Still Mixes Art and Science

On many extrusion shop floors, there’s likely a more experienced staffer who can tell something’s amiss with a line using only the instrumentation God gave him or her.

-

Augmented Auxiliaries At K 2016

Incremental improvements to existing technologies combined with altogether new advances at the giant show.

-

Precision Molding Without a QC Department?

At Prism Plastics, quality is baked into every step of the process. The result: 1 billion parts per year with a defect rate less than 1 ppm.

-

Graham, Blue Star Silicones Combine on Medical, Pharma Tubing

Collaboration intended to advance the development and testing of medical- and pharmaceutical-grade silicone tubing.

-

Profile Extruder Sees the Light

Rotuba exited the sheet business to focus on custom profiles for LED light fixtures. It now ranks as North America’s leading profile extruder in this burgeoning market.

-

AUXILIARY EQUIPMENT: New Controls for Conveying, Mobile Drying

New dense-phase conveying system among the new products Conair to display at K.

-

IPEG Buys Pelletron

Purchase puts IPEG in market for large conveying systems for resin plants.

-

Optimized Molding Is Possible With Material Drying, Handling

Injection speed and overall cycle time are often the focus for molders pursuing optimized processes, but for truly efficient production, molders should consider how and in what state material arrives at the machine.

-

Collaboration in Catheters

Medical Murray has developed innovative catheter technologies by working with its customers and down its supply chain.

-

Graham, Conair Team Up To Boost Medical Tubing Technology

Suppliers to house each other's equipment in their respective extrusion labs.

-

Pellet Production Is a Blast For This Processor

Maxi-Blast opens a plant with brand-new equipment to produce its own pellet blasting media.

-

Down in the Valley, Profiles Grow

Valley Extrusions carves niche in tight-tolerance, short-run tubing and profiles.

-

'Talking’ Machines Pave the Way for Processing Plants of Tomorrow

At the convergence of smarter equipment, open communication protocols, and more powerful networks, a new shop floor emerges where groups of intelligent machines work seamlessly as integrated systems.

-

Auxiliaries AT NPE: New Controls Link Auxiliaries

Industry 4.0—the internet of things—is bringing a new level of connectivity to auxiliary equipment. Here’s a rundown of developments there, along with other news in auxiliaries from the show.

-

Conair Expands Chinese Manufacturing With New Facility

New building covers 4500-m2 (48,000-m2) and will allow Conair to combine manufacturing and offices into one facility down the street from its former site.

-

EXTRUSION AND COMPOUNDING NPE: Flexibility, Speed and Quality

Extrusion processors need more—of everything—to compete. And suppliers responded in force in Orlando.

-

News Highlights from NPE2015

Here’s a first look at new technology in materials, auxiliaries, and all types of processes.

-

AUXILIARIES AT NPE: More Control, Flexibility, And Efficiency

These are key trends in the many kinds of auxiliary equipment displayed at this month’s show. You’ll also see equipment designed to be virtually ‘foolproof.’

-

Conair Lab Devoted to Pipe, Profile, Tubing Extrusion

New lab can develop and test complete extrusion systems for precision medical tubing to siding.

-

B&B Molders Sticks to Its Core— Core Values & Core Competencies

To compete in today’s market, you need good technology, but you also need to know what you stand for and what you’re good at.

-

Teel Plastics: Where Science, Tech, Quality and Innovation Meet

This family-owned custom profile and tubing business controls its own destiny by controlling, well, everything.

-

Solutions to Batch Blender Issues Save Money & Downtime

When a blender is operating poorly, odds are that the fixes are quite simple if you know what to look for.

-

Savvy Processors Reveal Best Practices on Drying

The processors speak: Here’s how some smart molders and extruders tackle the vexing problem of resin drying.

-

Granulate or Shred: Which Makes Sense for You?

That is the size-reduction question confronting many processors today. Look here for some guidance.

-

2013 was good for N.A. equipment suppliers; Can 2014 Overcome a Slow Start?

The North American plastics equipment market saved its best for last in 2013, delivering shipments valued at $335.1 million in the fourth quarter—the best three-month stretch of the year and up 3% from the previous quarter. Will that momentum hold in 2014, however?

-

Extrusion/Compounding at K 2013: Having It All

Extrusion processors no longer need to chose among speed, quality, and flexibility, based on exhibits at K 2013.

-

K 2013: More Efficient, Flexible & User-Friendly Auxiliaries

It’s hard to generalize about auxiliary equipment, but a few trends stood out at K, including: greater energy efficiency, ease of maintenance and cleaning, controls that provide more real-time and historical process information and greater ease of use.

-

Web-Enabled Auxiliaries Save Time And Shoe-Leather in Molding Plant

Internet connectivity for plastics equipment is a relatively new and growing technology. Here’s how it works at Samtec.

-

Pull Yourself to More Accurate, Repeatable Medical Tubing

The puller is the heart of the tubing extrusion process. While material throughput rate is generated by the extruder, and the tubing is initially formed in the die, it’s the puller that develops the ID/OD and wall thickness.

-

K 2013 Preview: Extrusion, Compounding, Recycling

Across all extrusion technologies, expect to see new standards in speed, quality, flexibility, and efficiency in both energy and material usage.

-

Troubleshooting Mold Temperature Control

Mold-temperature control is just one of many process elements that can affect the quality of an injection molded part.

-

Auxiliaries at NPE: News in Materials Handling, Cooling, Granulating, Welding, Testing, Decorating

Auxiliary equipment takes in a broad range of functions, from materials preparation to post-mold finishing.

-

Extrusion & Compounding at NPE: Advances Push Efficiency Envelope

Blown film towers may have been scarce, but there was no shortage of new technology aimed at helping to make extrusion processors more profitable.

-

How Gravimetric Control Systems Pay Off in Blow Molding

Gravimetric control systems offer blow molders improvements in processing efficiencies above and beyond their ability to regulate resin usage.

-

Auxiliaries at NPE: New Solutions from Material Preparation To Post-Mold Operations

There will be an extraordinary range of new auxiliary equipment on display at the show.

-

Custom Profile House ‘Flexes’ Processing Muscle

Specialty house avoids commodity markets and has entered the proprietary processing business with new product offering.

-

Central Drying Made Simple

Recent advances in technology have made the concept of drying in a central location—as opposed to right at the machine—more advantageous for certain kinds of processing operations.

-

On Site: Growth Through Innovation in Medical Tubing

By focusing on high-tech, quick-turnaround, turnkey solutions, Putnam Plastics has grown into a leader in the field of medical extrusion.

-

Extrusion: Multi-Pass Tubing Tank Offers Higher Quality, Resin Savings

A new cooling and sizing tank for extruded tubing reportedly allows processors to reduce wall-thickness tolerances and cut material use dramatically while increasing productivity and reducing floorspace requirements.

-

How to Set Up & Maintain An Efficient Resin Handling System

In today's world, having a reliable resin-handling and conveying system is as important as having reliable electrical power.

-

Progressive Injection Molder Pioneers in Thermoforming IML

When you’re a successful injection molder with more than 40 years under your belt and more than 50 presses producing 1.8 billion containers and lids for food-packaging containers annually, what do you do when you feel the time is right to expand?

-

NPE News Wrap-up: Resin Dryers

At least 16 companies introduced new dryers at the big show in Chicago. The new models span a range of drying technologies, but most sport features that save space and cost and make the dryers simpler and more reliable.

-

Heating & Cooling at NPE 2003

Smaller, more efficient, and environmentally friendly are the themes for new heating/cooling products at NPE.

-

Long-Fiber Thermoplastics Extend Their Reach

Smaller parts, a wider range of resins and reinforcements,and retrofittable molding equipment were among the news indirect-compounded long-fiber thermoplastics presented at a recent Plastics Technology conference. Extrusion and thermoforming are also new extensions of this process.

-

Six Things You Should Know About New Eco-Friendly Chillers

If you never paid much attention to what kind of refrigerant is circulating inside your plastics chillers, it may be time you did.

-

Process Cooling Goes for Performance Plus Affordability

At the NPE 2009 show in Chicago, half a dozen exhibitors showed new cooling equipment that emphasized improved performance at about the same or lower cost.

-

Materials Handling: New Equipment Emphasizes Efficiency & Value

Visitors to the recent NPE 2009 show in Chicago were looking for materials handling equipment that could do more than dry, blend, or convey resins. It had to do those things while saving energy, providing faster and easier maintenance, speeding product changeovers, reducing labor cost, minimizing waste, and providing better value for money. The new products cited below addressed those needs and more.

-

Cooling in Tough Times: How to Save Energy and Maintenance

In today’s down market, plastics processors are discovering a whole new set of problems related to operating at reduced capacity.

-

NPE 2009 Wrap-Up: New Machinery for Extrusion and Compounding

Extrusion machinery at the June NPE show in Chicago showed inventive ways to get more out of your floorspace and materials.

-

Energy-Saving Dryer Pays Off In an Uncertain Economy

Plastics processors struggling through the recession need to save energy costs where they can, they need an affordable means to do so, and they could use energy-saving technology that pays for itself during times when plant throughputs are variable and below optimum capacity utilization.

-

NPE 2009 News Flash

Injection MoldingHybrid Press Has Electric ClampNew injection presses that combine servo-electric and hydraulic movements to achieve high performance with energy efficiency will be discussed by Arburg Inc., Newington, Conn.

-

Stop Profile Warpage

Processors today want to run faster, minimize scrap, and do short production runs that may only last a few hours.

-

HOW TO COMPARE DRYERS? A Complex Challenge With No Simple Answers

Is one type of resin dryer faster or more energy-efficient than another? That question prompts competing claims from suppliers—but very little concrete data. When one vendor performed controlled tests to get some answers, its results, published here for the first time, prompted further debate about the difficulties of making valid comparisons and the many complex issues involved in dryer selection.

-

Coloring on the Machine: You Can Do It Right

Coloring at the machine can offer significant cost benefits, including lower material inventory costs and improved process flexibility when compared with the cost of buying precolored resin or installing a large-capacity central blender to premix resin and color concentrate.

-

Extruding Biopolymers: Packaging Reaps Cost Benefit of Going 'Green'

Plastics made from renewable carbon chains, not fossil carbon from oil or gas, are suddenly a solid commercial reality. The draw isn’t just “green” marketing, but the “green” of stable prices not linked to petrochemicals.

-

NPE 2006 News Wrap-Up: Materials Handling: A Host of Refinements and Updates

NPE 2006 held no revolutionary changes in dryers, blenders, feeders, loaders, or conveying controls, but widely adopted improvements make the newest models easier to use and maintain—and easier on the budget, too.

-

NPE 2006 News Wrap-Up: Brains and Brawn - New Robots Are Handier Than Ever

Injection molding robots introduced at NPE pushed the work envelope for speed, reach, payload capacity, ease of programming, and ability to handle more sophisticated tasks.

-

NPE 2006 News Wrap-Up: Recycling and Scrap Reclaim

NPE was full of new equipment and systems for recapturing valuable in-plant scrap and post-consumer/post-industrial plastic waste. Recovery of PET packaging and film or fiber waste were particular areas of emphasis, as were lots of new granulators, from the world’s biggest to micro-size and even ‘clean-room’ models.

-

What to See at NPE 2006: Injection Molding

Energy-saving all-electric machines will continue to be a big draw at NPE, where new designs or upgraded models will be found in virtually every press maker’s booth.

-

What to See at NPE 2006: Materials and Parts Handling

Dryers, feeders, blenders, loaders, metal detectors, level sensors, mechanical and pneumatic conveyors, silos, bins, pumps, filters, valves, box fillers, bag dumpers, and materials-handling control systems constitute one of the biggest categories of products on display at NPE.

-

Resin Dryers: Which Type Is Right for You?

Processors today face bewildering choices of at least five basic types of dryers, whose capabilities are subject to conflicting claims from equipment suppliers. For the buyer, the most basic questions are: How much drying is needed for the job and which dryer types are up to the task?

-

Six-Axis Robots: Where They Fit in Injection Molding

Injection molded parts are typically demolded with simple pick-and-place automation—a top-mounted, gantry-style (also called Cartesian, linear, or traversing) three-axis robot.

-

Trouble with Your Dryer?

Although pellet drying is a relatively simple process, it is occasionally a source of consternation.

-

Improved Technology Tightens Your Grip on Materials Inventory Control

Know what's new in paddle switches or weight-and-cable sensors? What about capacitance, vibratory, and ultrasonic level gauges? Are radar or laser systems worth the money? It's time to get educated: Having the right tools for materials management is more important than ever.

-

New Crowd of Servo Robots Debuts At Two Recent Shows

The vast majority of new robots introduced at two recent trade shows were all-servo models tailored for speed and precision.

-

Family Lumber Business Turns To Plastics

Five years ago, Quality Wood Treating in Prairie Du Chien, Wis., was a 30-year-old family lumber business and one of the largest wood pressure-treaters in the country.

-

New Granulators Galore at NPE

Processors with scrap to grind must have noticed the prominence of screenless granulators with distinctive hooked “S-rotor” blades at the NPE show in Chicago.

-

NPE News Wrap-up - Water & Oil Temperature Control

If you’re the sort of manager that can’t resist checking up on your plant after you go home for the night, now you can click on your web browser and read out mold temperatures right there on your PC.

-

NPE News Wrap-Up: Materials Handling

The big show in Chicago presented more new loaders, feeders, blenders, and conveying controls than you could count. They’re more flexible, easier to maintain, and easier to control. Many are web-enabled, and some are lower in cost.

-

NPE News Wrap-up: Robots

From micro to maxi, from simple sprue pickers to sophisticated six-axis models, NPE had it all. A raft of new robots, faster and smarter than ever, will help make automation an irresistible choice for U.S. molders.