Compounding and Injection Molding Combined in Circularity Display

NPE2024: KraussMaffei aims to “make plastic green” with in-booth moldings and recycled plastics converted into other applications through a combination of injection molding, extrusion and inline compounding.

KraussMaffei will promote sustainability across all its manufacturing platforms, including injection molding with a series of displays emphasizing circularity and carbon footprint reduction. At the show, KraussMaffei will mold single-use medical blood vials and then, through a series of processes, convert them into durable, long-life bottle openers.

An all-electric PX 251-1400 will mold medical blood vials from a 32-cavity mold using ExxonMobil PP 9074 MED material. After shredding, these vials serve as base material for the upcycling process carried out on the ZE 28 BluePower twin-screw extruder. At the extruder, various additives (including bonding agents and liquid pigments) are added, mixed and homogenized. The resulting compound is fed to an all-electric PX 81-180, which will utilize the company’s APCplus dynamic control to account for viscosity fluctuations in the recycled blood-vial resin and mold bottle openers.

GX 1100-4300 DCIM system features a single-screw extruder in a piggy-back position on top of the molding machine. Source: KraussMaffei

Elsewhere, KraussMaffei’s Direct Compounding Injection Molding (DCIM) process will produce reusable crates from three different recycled materials. The GX 1100-4300 DCIM system features a single-screw extruder in a piggyback position on top of the molding machine. The extruder will convey compounded melt into the plasticizing unit in a single heating process, reducing heat degradation of the polymer. This one-step process also reduces energy consumption and carbon dioxide output. In this cell, KraussMaffei’s smartOperation machine function simplifies press startup and control.

The company will also showcase a MuCell screw with 30% higher plasticizing performance. The HPS-Physical Foaming screw has a longer three-zone area, which can be universally used for all plastics, including those with and without fiber reinforcement. This increase enables smaller screw diameters to be selected, reducing overall investment, or it can enable greater output by applying the same screw but getting more production.

A PX 121-180 SilcoSet will mold LSR headlight lenses with the help of the APCplus software. ACH Solution supplied the 2-cavity mold and its Servoshot 2G electro-pneumatic valve-gate system, which has needle valve control down to 2 µm. A KraussMaffei LRX 150 linear robot using an end-of-arm-tool from ACH Solution enables inline inspection, including weight check, and separation.

These LSR headlight lenses apply valve-gate technology from ACH Solution. Source: KraussMaffei

KraussMaffei will also highlight its partnership with the National Institute for Aviation Research (NIAR) at Wichita State University at NPE2024. NIAR will bring its “Frankenstein” manufacturing demonstrator to Orlando. This demonstration model showcases different examples of automotive-matured ultrahigh-rate manufacturing technologies to aerospace, part of a joint KraussMaffei/NIAR research program. NIAR will also show an aircraft window plug that is undergoing certification efforts for passenger-aircraft-to-cargo conversion activities at NIAR. These composite parts are manufactured using the company’s FiberForm technology, which combines thermoforming of organic sheets and injection molding in a single process.

KraussMaffei’s booth will also feature a driverless concept vehicle designed for the year 2035, developed at Clemson University with the help of ExxonMobil Chemical and Honda North America. The resulting car is composed 18% by weight from plastics and composites — nearly double the 10% market average.

This Clemson University driverless car concept is made up of 18% by weight of plastics and composites. Source: KraussMaffei

Also in mobility, TIME Bicycles, in partnership with KraussMaffei, Fraunhofer USA and Clemson once again, will highlight their special development project to introduce High-Pressure Resin Transfer Molding (HP-RTM) to the cycling industry. At the show, the first U.S.-produced HP-RTM bicycle will be on display. Visitors can register to win the bike, which has a retail value of $8,000. Founded in France in 1987, TIME Bicycles was and is the leading European manufacturer of carbon fiber bicycles, specializing in resin transfer molding (RTM).

The first U.S.-produced HP-RTM bicycle will be on display at NPE2024. Visitors can register to win the bike with a retail value of $8,000. Source: KraussMaffei

Related Content

A Recycling Plant, Renewed

Reinvention is essential at Capital Polymers, a toll recycler that has completely transformed its operation in a short period of time.

Read MoreCompatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

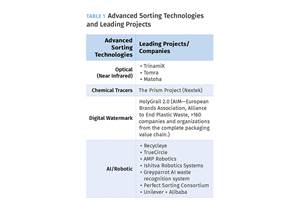

Read MoreRecycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreResins & Additives for Sustainability in Vehicles, Electronics, Packaging & Medical

Material suppliers have been stepping up with resins and additives for the ‘circular economy,’ ranging from mechanically or chemically recycled to biobased content.

Read MoreRead Next

Recycling Challenges Become Opportunities with the Aid of New Technologies

The latest recycling equipment on view at the K Show handles more materials, is more efficient and produces higher quality output than ever achieved before.

Read MoreTechnology Combines Processes for Strong, Lightweight Components

Krauss Maffei's FiberForm technology in an injection molding macine enables the production of fiber-reinforced plastic components.

Read MoreKraussMaffei and NIAR Propel Injection Molded Thermoplastic Composites

The maker of plastics processing equipment has placed a machine and an injection molding expert in NIAR’s ATLAS lab in Wichita, Kansas, to help molding, composites and aerospace take off.

Read More