Decorating/Finishing: New Automotive Decorative Laminating Technology Cuts Costs, Boosts Quality

Describing it as a “revolution in vacuum lamination,” Kiefel GmbH in Germany has launched Tailored Blank Lamination (TBL) technology for automotive interior components such as door and instrument panels, consoles, storage compartments, pillars, etc.

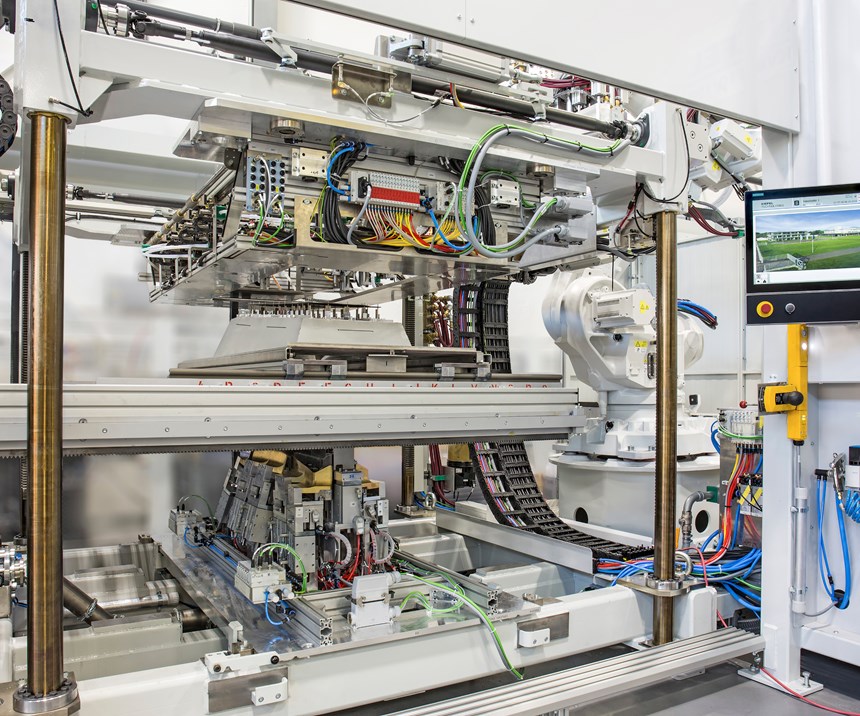

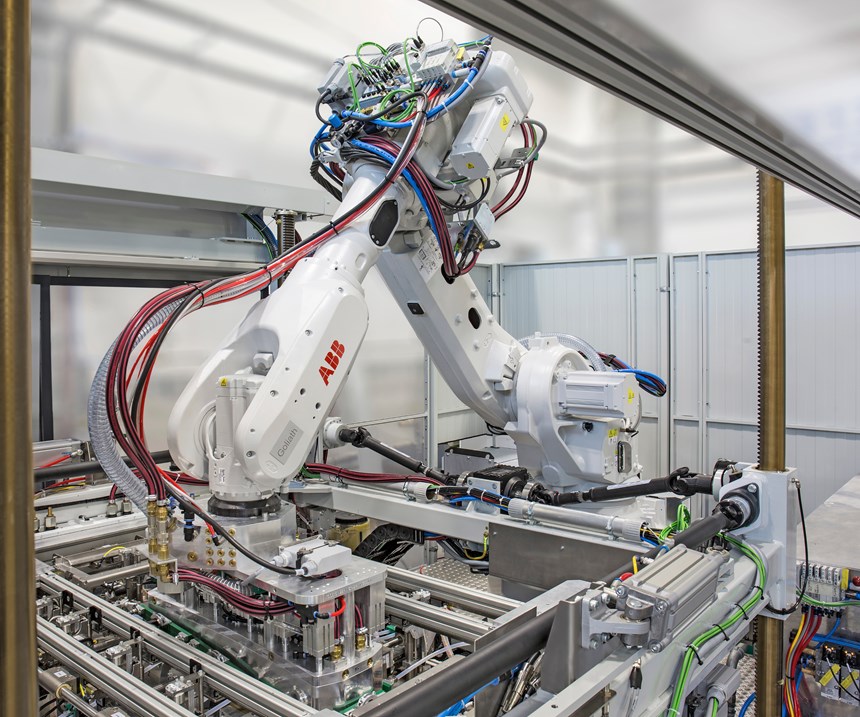

Describing it as a “revolution in vacuum lamination,” Kiefel GmbH in Germany has launched Tailored Blank Lamination (TBL) technology for automotive interior components such as door and instrument panels, consoles, storage compartments, pillars, etc. Unlike the usual roll-to-roll lamination process, the key feature of TBL is feeding precision-precut film blanks from a stack into the vacuum laminating press to apply decorative soft-touch surfaces to injection molded substrates. A robot integrated into the vacuum-laminating station picks up the injection molded substrates. A carrier frame with multiple servo-driven grippers that can move freely in three dimensions, positions the film blank on the substrate without stretching. After laminating, the robot transfers the component to the next station, such as edge-folding or punching. (Cutting knives integrated into the TBL tool reportedly produce exact film overlap length for subsequent edge-folding.)

Compared with conventional vacuum lamination, Kiefel says TBL can save up to 40% in film consumption, while also reducing film stretch and grain washout (film draw-off) by 25-30% to a range of 10-15%, with uninterrupted soft touch. The process is also highly automated, reducing labor costs, and the new TBL machine system occupies a footprint 50% smaller than conventional vacuum-laminating systems. TBL is also said to be capable of handling undercuts and sharp corners and flanges. TBL is applicable to both vacuum and press lamination.

Related Content

-

Benchtop LSR Injection Molding Machine Launches

APSX LLC, which previously marketed the APSX‑PIM desktop thermoplastic injection molding machine, has debuted the APSX‑LSR — a benchtop liquid silicone rubber (LSR) injection system.

-

Through Thick and Thin: Reflecting on Injection Molding Thin and Thick Walls

Author considers time molding thin-wall food packaging and thicker-walled interior automotive trim, weighing the differences and similarities in process, molds and materials.

-

BMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).