Foam Molding Simulation Gains Better Bubble-Shrinkage Prediction

Microcellular foam molding simulation improves prediction of cell size and distribution in thin sections, core-back processes.

Share

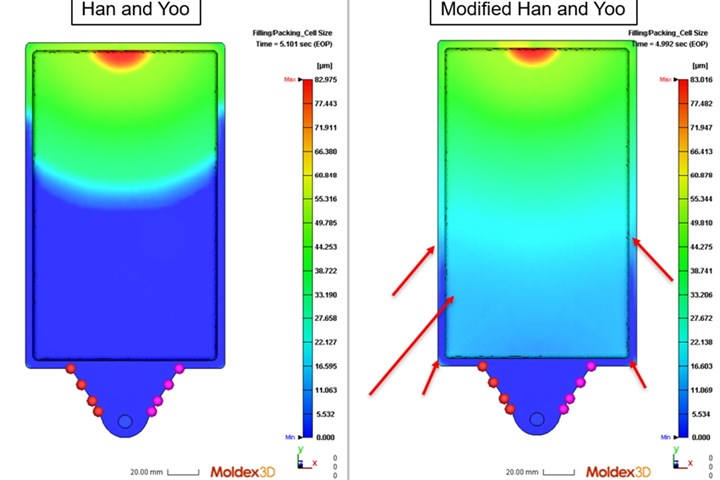

In foam injection with supercritical nitrogen or carbon dioxide, the gas and melt are mixed in the screw into a uniform, single-phase fluid. During injection into the cavity, instantaneous pressure release causes thousands of tiny bubbles to nucleate and grow. Until now, the industry has used the Han and Yoo model of bubble-growth dynamics to simulate and predict bubble growth. But the accuracy of such predictions reportedly can be compromised by complex part geometry and by processes such as core-back molding.

For instance, in parts with thin sections, the melt pressure may remain high—even higher than the packing pressure—thereby compressing the bubbles and even causing some to redissolve into the melt and disappear. And in the core-back process, bubbles are released upon initial injection (pre-foaming), but then packing pressure is applied, causing the bubbles to shrink and eventually redissolve in the melt, only to nucleate and grow again (secondary foaming) when the pressure is released. Under these circumstances, the Han and Yoo model reportedly cannot accurately predict bubble shrinkage under pressure and ultimate cell size and structure.

Thus, Moldex3D (Coretech System Co.) collaborated with a Japanese university to develop a Modified Han and Yoo model, which has now been added to the Moldex3D 2021 simulation software package. Experimental results are said to closely match the predictions of this updated model for bubble shrinkage under pressure in thin sections or core-back processes. According to Moldex3D, the original Han and Yoo model tends to underestimate the disappearance of bubbles in thin sections where pressure remains high. What’s more, applying the modified model to the core-back process can predict the required packing time to redissolve all the pre-foaming bubbles back into the melt before the core is retracted.

Related Content

-

How to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

-

Understanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.