Upgraded Simulation Package Adds Nozzle Zone & Conformal Cooling ‘Wizards’

Wizards assist conformal-cooling layout and simulation of melt compression in the nozzle in Moldex3D 2021.

Share

Read Next

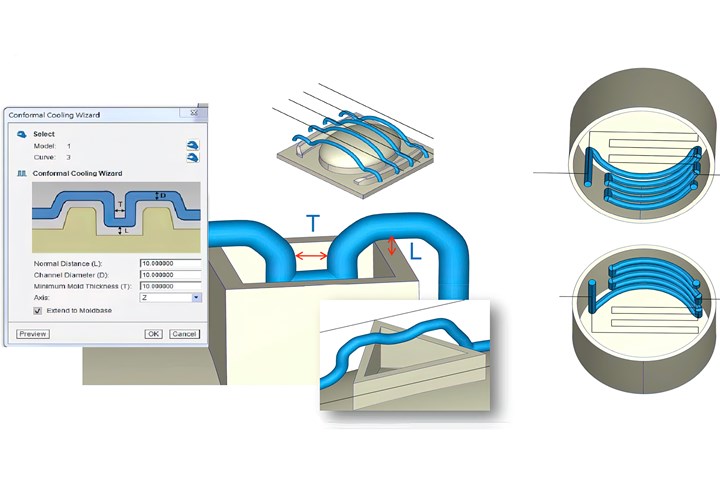

New Conformal Cooling Wizard quickly creates a cooling layout from a 2D mold model.

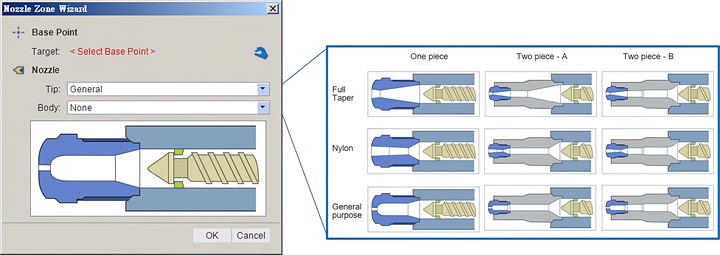

A host of speed and accuracy enhancements, plus several new “wizards,” are featured in CoreTech System’s release of Moldex3D 2021, the latest version of its molding analysis software package. One new wizard helps the user quickly create a conformal cooling system from a 2D mold layout. A new Nozzle Zone Wizard provides a quick and simple workflow to establish a 3D barrel compression model and to mesh the nozzle zone. Another new wizard establishes the gate area and shows the shortest path from melt entrance to each gate. The user can select the melt path from the list of possible paths, which highlights the melt path and computes its length.

More accurate shrinkage and warpage predictions are claimed for a feature in the new release that considers the “solidification effect”—that is, the abrupt increase in melt viscosity just before freezing, which departs from the standard viscosity model. The model also applies solid-state shrinkage properties to the warpage calculation. In addition, mechanical property simulation is introduced to optimize the shrink/warp prediction for short-fiber reinforced compounds. There’s also a new Linear Buckling Analysis for calculating large deformations in warpage predictions.

New Nozzle Zone Wizard provides a quick and simple workflow to establish a 3D barrel compression model and to mesh the nozzle zone.

For foam molding, new models predict bubble shrinkage during foaming. For injection-compression (and straight compression) molding, the 2021 update offers improved display of melt-front movement during the compression stage. For water/gas assist, better accuracy is claimed for simulation of overflow gate control. And Powder/Filler Analysis is said to be faster and to provide a clearer display of concentration distribution.

Moldex 3D 2021 supports Windows 64-bit computers. Among a host of other improvements are these:

• Faster solver calculation—up to twice as fast with 16-core computing and more than three times as fast with 32 cores.

• Improved accuracy predicting the timing and pressure point for velocity/pressure switchover by accounting for the empty space near the nozzle tip after suckback.

• More accurate simulation via an enhanced wall-slip model, which accounts for how wall slip changes with shear stress.

• Improved meshing around curvature areas and joints; easier fixing of mesh defects; and around 15% reduction in surface-element count without sacrificing mesh quality.

• Addition of 19 thermoplastic materials, including nine TPEs, to the resin database; and addition of 582 injection machines and new controls to the Machine Bank.

• Easier sharing of simulation results among project teams with reduced file sizes.

• Enhanced simulation of thermoset RTM and IC chip “potting” processes.

Related Content

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

-

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

-

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.