Heating/Cooling: Advanced Mold-temperature Control at K 2019 Show

Larger electronic TCU and automatic mold blow-out function debut from Engel.

Engel showed two enhancements of its program to digitalize mold-temperature control at October’s K 2019 show in Düsseldorf. One exhibit was the new e-temp XL model, a larger version of its TCU with variable-speed pump, built for Engel by HB-Therm of Switzerland. The new unit has pump capacity up to 32 kW, double the previous maximum size.

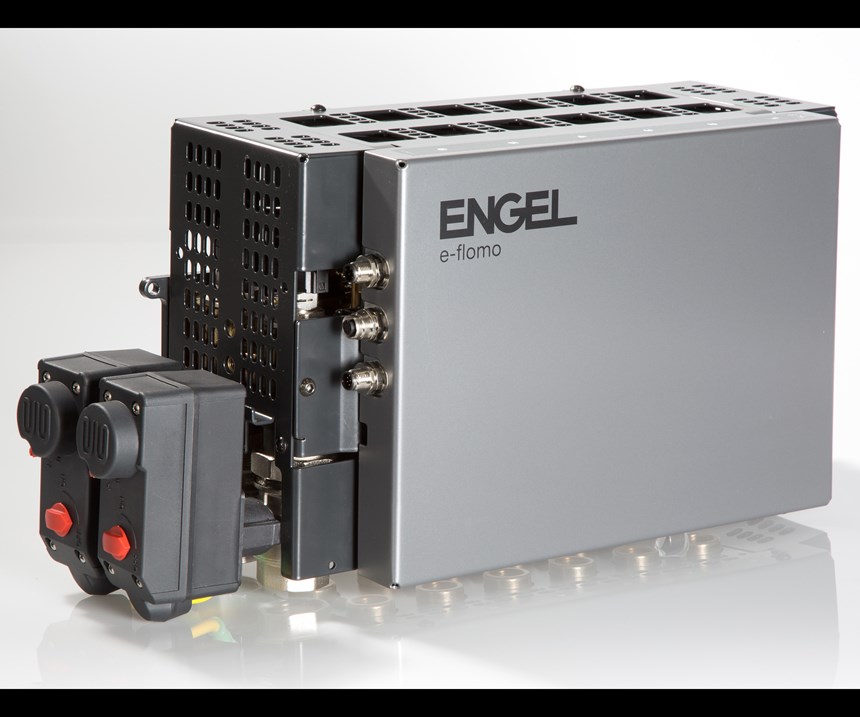

The e-temp TCUs can be integrated with an Engel injection machine’s CC300 control via Engel’s iQ flow control software, which dynamically regulates the volume flow rate to match the process conditions. To make this possible, another key element of the system is Engel’s e-flomo electronic water manifold (pictured), which can monitor and control flow and temperature in individual water channels. A new e-flomo feaure introduced at K 2019 is automated, sequential air-purging (blowing out) of the manifold circuits in the injection mold when changing molds or mold inserts. This is normally a manual process that is time-consuming and not always reliable, as compressed air often does not flow evenly through the circuits. The new optional feature for the premium version of e-flomo is said to speed mold setup and minimize the risk of residual water remaining in the cooling channels.

Related Content

-

Is Your Water System Setup Helping or Hurting Your Molding Plant Productivity?

The plant water system is a critical component of an injection molding facility. A poorly designed or maintained water-cooling system can have a serious impact on production efficiency and cause many maintenance issues. Here’s what you need to know — and ask — to prevent those problems.

-

Captive Molder Beefs Up Auxiliaries to Boost Quality, Consistency

SeeScan adds conveying, drying, feeding and chilling technologies to improve quality — and enhance employee safety — in production of its underground/underwater inspection systems.

-

Descaling Pump Cleans Heating and Cooling Circuits

Mouldpro’s compact and portable descaling pump keeps heating and cooling circuits on molds and molding machines clear of rust and limescale deposits.