New Line Offers Efficient 'No Dry' PET Sheet Extrusion

System optimized for PET processing recently received an FDA non-objection letter for production of food-grade thermoforming sheet.

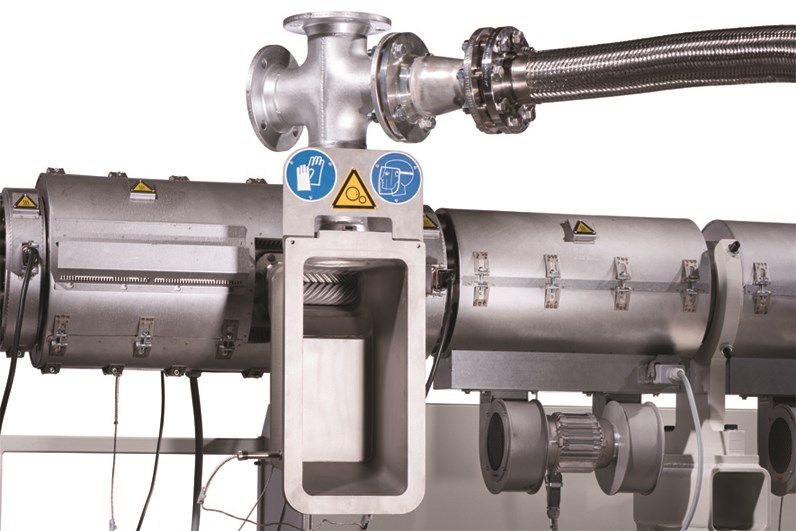

The STARextruder series from Battenfeld-Cincinnati is designed mainly for PET sheet. The processing unit consists of three sections: a single-screw zone for material plastification; a planetary-roller section for degassing under high vacuum; and an optimally configured discharge zone. The planetary-roller degassing zone reportedly provides highly efficient degassing of the melt. Because of the functionality of the degassing section, the melt is rolled out in very thin layers, creating an extremely large surface area. Both effects counteract material degradation of the material and significantly contribute to product quality.

STARextruders are said to save energy by significantly reducing drying costs. Maintenance costs are lower thanks to higher wear resistance of the planetary-roller section. A switch from PET to PP or PS processing is also said to be possible without a screw change. The machines’ proven concept enables the processing of PET bottle flakes without pre-conditioning. This process has recently been issued a letter of non-objection by the U.S. FDA.

The STARextruders are available in machine sizes of 90, 120 and 150 mm, and are suited for small and medium outputs ranging from 1300 to 2600 lb/hr.

Related Content

-

Upgraded Former is Faster, More Precise

New features reportedly offer more efficient production of trays, containers, hinged boxes, pallets, blisters, lids and technical products.

-

Brueckner Group USA Moving to Bigger Space

New facility in New Hampshire will serve the local customer base better and enhance capabilities in the North American market.

-

Sustainable Materials is Focus of Thermoforming Exhibits at K 2022

Thermoforming equipment makers including WM, Kiefel, and OMV will showcase processing of recyclable and biobased materials.