Patented Laser Welding Process Boosts Efficiency

Evosys’ new AQW welding process said to process selected plastics such as PC even more economically.

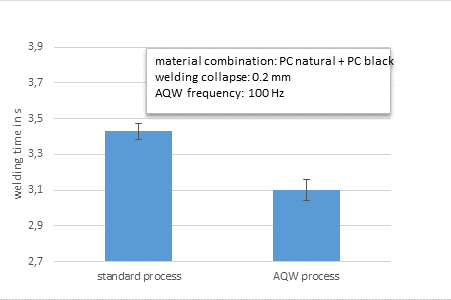

A patented welding process that reportedly leads to a significant increase in efficiency has been launched by Germany’s Evosys Laser GmbH (U.S. office in Auburn Hills, Mich.). With the new Advanced Quasi-Simultaneous Welding (AQW), selected plastics such as PC can be processed even more economically.

Numerous test series have shown that welding times can be significantly reduced in some cases. The process makes use of the absorption properties of the plastics and combines two different wavelengths that are alternately guided over the welding zone in a controllable pattern. According to the company, experience with AQW shows an improvement in process time compared to the standard process with only one laser source. The new process has been applied to PC type materials, but other common plastics are also conceivable in the future.

Parallel to the patent granting process, the necessary system technology for the AQW process was developed and optimized for series use. "Our customers can test the process extensively in our technical center at any time and use it later for their series production," explains Frank Brunnecker, managing partner of Evosys Laser GmbH.

Related Content

-

Can Plastic Recyclates be Welded Ultrasonically?

What is possible with ultrasound? Will the result with recycled plastics material actually be worse than with standard material? Do we have to adapt our technology?

-

X-Ray Vision Inside Parts Gets More Affordable for Processors

Shimadzu’s new benchtop x-ray CT scanner provides internal and external metrology and flaw detection at a fraction of the previous cost.

-

Sidel Acquires Another Label Machinery Firm

Makro Labelling adds low- to medium-speed technologies.