Products

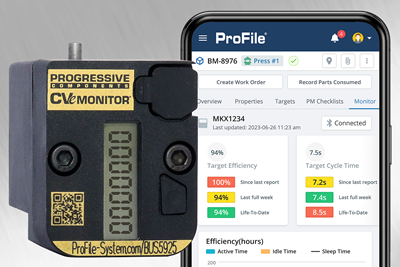

Real-Time Mold Monitoring at NPE2024

Progressive Components’ latest mold monitoring platform, the ProFile v4 asset tracking system, is showing actual mold data being collected and managed.

Read MoreStreamlined Drying Process Speeds Up Changeovers

NPE2024: Maguire demonstrating increase in productivity possible by vacuum drying.

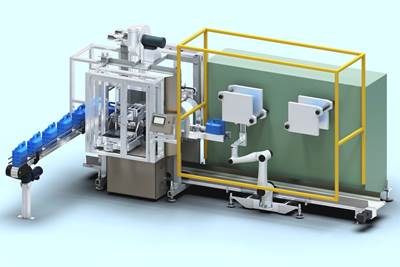

Read MoreCobot Takeout System for Shuttle Machines

NPE2024: Proco Machinery upgrades its Robopik bottle takeout system for shuttle blow molders with the addition of a collaborative robot.

Read MorePelletizing System for Engineered Resins and Recycled Materials for Optical Molding

NPE2024: Matsui America is introducing the Raptor 22 pelletizing system.

Read MoreNew Pump Rewrites Conveying Rules

NPE2024: Smart Pump technology brings more flexibility and finesse to resin conveying.

Read MoreDuo Shredder Upgraded With Reinforced Pusher System

NPE2024: Rapid Granulator presents its latest size reduction technology.

Read More‘Cutting-Edge’ Portfolio of Electrically Conductive Plastics

NPE 2024: Premix Group is unveiling its Pre-Elec compounds and concentrates for ESD, explosive atmosphere, liquid handling and metal replacement applications.

Read MoreHybrid EPDM-TPE Adhesion Compounds for Automotive Industry

Kraiburg’s new compounds targeted to auto sealing and exterior sector applications and toolmakers.

Read MoreTomra GAINnext Uses Deep Learning Technology to Purify PET Streams for Recycling

NPE2024: AI sorting add on for the company’s Autosort systems aids in removing elusive plastic contaminants.

Read MoreUpgrade to Accelerated Artificial and Natural Weathering Testing

NPE 2024: Atlas’ S³T system is designed for the company’s Weather-Ometer Ci4400 and Ci5000 instruments

Read MoreDryer, Blender for 'Real Time' Regrind Usage

NPE2024: Dri-Air Industries, Maguire Products, join forces on the former’s second generation of on demand drying/blending systems for the circular economy.

Read MoreMeasure Viscosity Precisely, Repeatably

NPE2024: The PVS viscometer from LAUDA Scientific is billed as the routine instrument for aggressive solvents in polymer chemistry.

Read More