Wittmann Shows Its 'Pathway to 4.0’

Wittmann Battenfeld’s operating work cells demonstrate self-adjusting machine controls, auxiliary equipment fully integrated with the injection press, and predictive-maintenance programs.

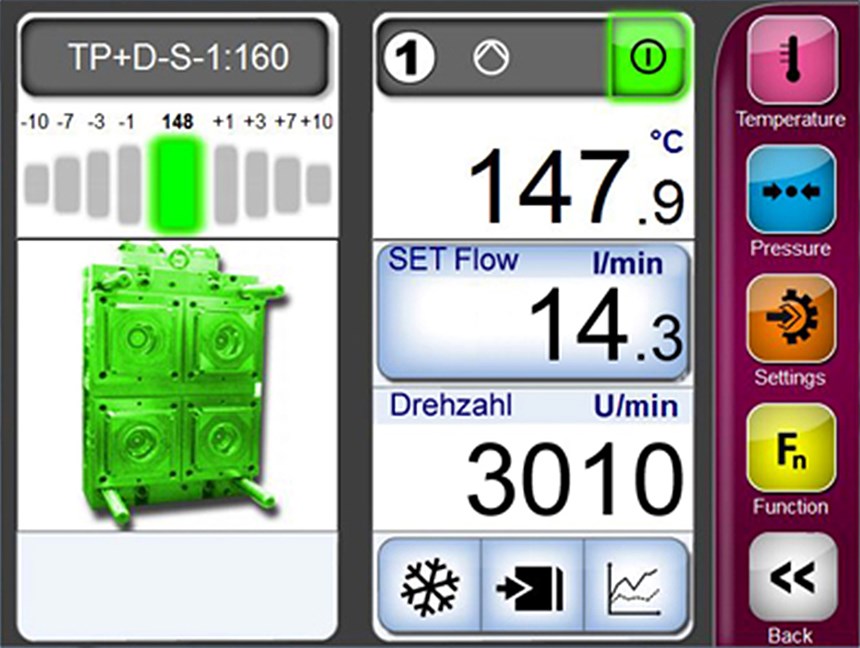

Wittmann Battenfeld will demonstrate its HiQ-Melt, HighQ-Flow, and HiQ-Cushion “smart machine” technologies as part of its “Wittmann 4.0” program. What’s more, this firm is in the unusual position of making both injection machines and a full range of auxiliaries. It has therefore employed OPC-UA and other technologies to link all these devices with the aid of a secure Wittmann 4.0 router.

This router is a key to Wittmann’s “Plug & Produce” initiative, which makes it possible to store and recall all parameter settings for a particular job within the Unilog B8 machine control—everything needed to set up the molding machine, robot, dryer, chiller, TCU, and blender. If this data is not recorded on the machine, it can be retrieved from an MES system.

Wittmann 4.0 integration will be demonstrated on six work cells at NPE, the most elaborate of them involving integration (via the Wittmann 4.0 router) of the robot, TCU, blender, Flowcon Plus electronic water-flow controller, HiQ-Flow and Cushion functions on the injection press, and two cavity-pressure sensors. Non-Wittmann units also integrated into the same network via the router and a Windows-based controller include a Gammaflux hot-runner controller, HRSflow servo controller for five valve gates, and Opti Check from Schneider Form, which measures the deflection of the mold during injection. This cell will also show the new CMS (Condition Monitoring System) for predictive maintenance.

Related Content

-

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

-

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

-

How to Stop Flash

Flashing of a part can occur for several reasons—from variations in the process or material to tooling trouble.