Redefining Thermoplastics Efficiency

Chem-Trend introduces its purge compound series, Ultra Purge 1000.

Share

Introducing a new purge compound series – Ultra Purge™ 1000 – highly efficient for purging thin-wall packaging single face tools and stack tools.

Why it matters:

- Removing residue and color from hot runners is challenging with no truly efficient solution available, until now.

- Designed to purge the machine “on the fly” requiring no change of machine settings and no soak time during the purging process.

- Contributes to a reduction in machine downtime and waste without any additional capital expense.

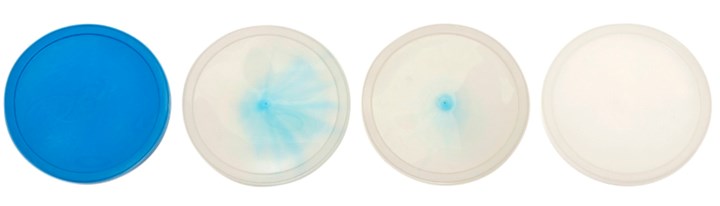

In a trial of Ultra Purge™ 1000, one thin-wall packaging injection molder was able to reduce downtime from 4 hours to 1.5 hours when undergoing a color change from blue to white, resulting in a 63% reduction in time spent, and 68% reduction in scrap due to a more efficient and complete cleaning.

Request your free sample today. CHEMTREND.COM/contact

Read Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE 2024.

Read More