Multicomponent

Completely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreMolder Opts for Machine Flexibility for Complex Jobs

AE Plast opted for tiebarless multimaterial Engel victory machines as it took on complex parts for the appliance and power tool market, including a 3K housing for Dremel’s rotary tool.

Read MoreFakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

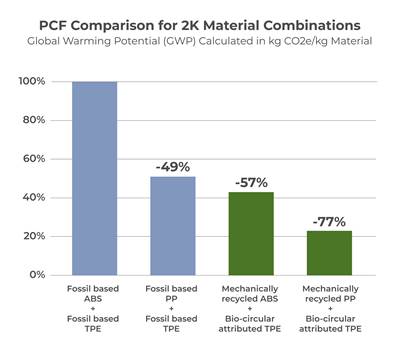

Read MoreMore Sustainable Two-Component Overmolding

Swedish compounders HEXPOL TPE AB and Polykemi AB have collaborated on a 2K sustainable development project for consumer products.

Read MoreVideo: Ultradent Bags Both Hot Shots Prizes at PTXPO 2023

Topping five other entries in voting by fellow molders, the Ultradent team talks about their Hot Shots sweep.

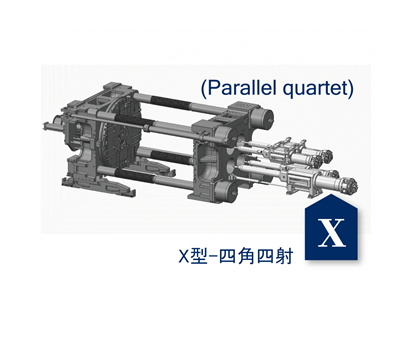

WatchNew Multicomponent Injection Molding Machine Line Launches

FCS Group’s X-Type parallel quartet injection molding machine features four injection units aligned in parallel for a smaller footprint.

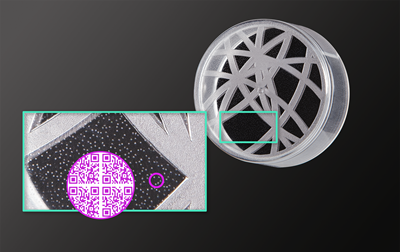

Read MoreMold, Hot Runner, Digitization and Process Monitoring at K 2022

The Barnes Group’s Molding Solutions division companies will highlight new mold and hot runner technologies at its own booth and at several machinery partners during K 2022.

Read MoreZAG Equipment Sales Partners with Portugal’s Plasdan of Portugal

Under the agreement, ZAG will sell and service Plasdan’s add-on injection units and fully electric rotary tables for multicomponent injection molding.

Read MoreMulticomponent Mold Combines Capping and Unscrewing Functions for Pharma Closure

Braunform says its patented RotaricE² mold, which will mold Luer lock pharmaceutical closures in Arburg’s K 2022 booth, allows the use of one tool and one machine, versus two, while eliminating post-mold assembly.

Read MoreDual Injection Units on a Smaller, Electric Press for 2K Medical Molding

Engel extends its combi M dual-injection unit technology to a smaller tonnage machine with a horizontal indexing table for the first time at K 2022.

Read More