Mold, Hot Runner, Digitization and Process Monitoring at K 2022

The Barnes Group’s Molding Solutions division companies will highlight new mold and hot runner technologies at its own booth and at several machinery partners during K 2022.

The companies of Barnes Group’s Molding Solutions division—männer, Foboha, Synventive, Thermoplay, Priamus and Gammaflux—can be found at its own K booth, as well as in molds, hot runners and controls at the booths of Arburg, Netstal, Yushin, Fanuc and KraussMaffei, exhibiting under the them of “Share and Bundle”.

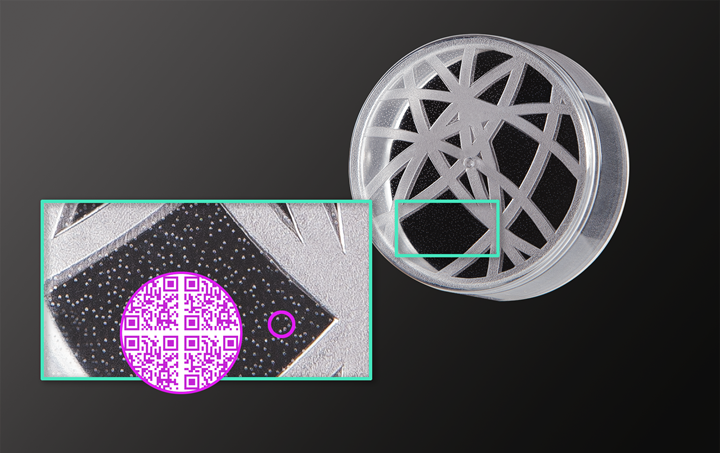

At its own Hall 1 booth, Molding Solutions will show how digitization can simplify recycling via a digital watermark. Closures molded from a biobased resin are given a digital watermark that allows recyclers to automatically separate the caps. The digital watermark, which was laser engraved onto the mold cavity, is detected by a special camera. By scanning the product with a digital watermark app, consumers can access a digital product passport with recycling related information.

Digital water marks help recyclers and consumers identify the plastic in question to assist in end of life.

Photo Credit: Molding Solutions

The company will also debut an intelligent monitoring system at the show. Barnes Connectia Cloud will give users access to data collected by the moldMIND program, which documents relevant process data and events for injection molds in real-time throughout their operating life.

Synventive, meanwhile, will showcase a new electric valve gate. The company says the compact eGate Sync will complement the legacy eGate system, offering plug-and-play installation and simple user interface.

Molding Solutions is also launching a new online hot runner configuration system: hotrunner.shop. With this program, 3D data of 2-, 4-, or 8-drop hot runner systems featuring nozzles from männer and Synventive can be created within minutes. The step-by-step configuration system draws on a material database of more than 12,000 resins and allows customers to generate customized 3D data through the application check. For applications outside the system’s guidelines, a follow up with an application engineer is set up. männer and Synventive’s configurators are currently available today, with the company noting that Thermoplay’s is expected to launch “soon”.

For multi-cavity applications, männer is expanding its Packaging and Slimline products with additional valve gate nozzles. männer says the Packaging range for high-speed molds is complemented by the MCN-EP featuring a small diameter and permanently centered valve-gate pin. The company says the nozzle tip’s patent-pending design facilitates high-precision gating, while also enabling the correction of tip protrusion without reworking.

Like the MCN 8 and MCN 6.5, the new MCN 5 valve-gate nozzle from the Slimline series targets tight installation conditions in high-cavity molds. Here, männer says the manifold has been optimized, applying artificial intelligence and a 3D-printed manifold to show how the design of the flow bore can help a non-symmetrical 6-drop hot runner system achieve “perfect” balancing.

The digital water mark is laser etched onto the mold cavity surface.

Photo Credit: Molding solutions

Thermoplay has added two nozzles for larger shot sizes to its “TFS” open nozzle series for side gating. In addition, Thermoplay has created nozzles for a 45° gate to mold conical parts as well as multi-tip nozzles for small parts that are gated with several injection points. Thermoplay said it views 3D printing as a means to faster delivery times and is introducing a new multi-nozzle with a collar made via additive manufacturing.

Around the Show

Beyond its own booth, Molding Solutions companies will display an additional five molds and several hot runner systems, as well as temperature controllers and process control systems, at partner booths. At the KraussMaffei booth, medical consumables will be molded from PP in männer’s 96-cavity mold, after which the material is granulated for the production of automotive parts,

Another turnkey system from manner, built around a 64-cavity pipette tip mold and hot runner from männer will run at Netstal’s booth on an Elion 2800-870. At its booth in Hall 11, automation supplier Yushin will rely entirely on lateral demolding robots. Blister packs are produced in a 16-cavity männer mold and removed laterally, from a Netstal Elion 800. Thanks to the cycle time-optimized männer mold, the performance of the Netstal injection molding machine and the high-speed robot from Yushin, cycle time can be reduced by up to 3.5 seconds.

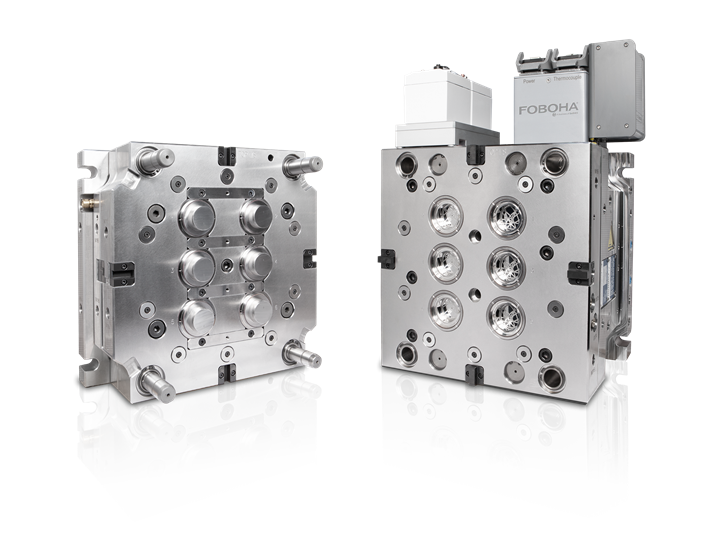

At Fanuc’s booth, Foboha’s 48-cavity mold will showcase cavity balance and energy efficiency. Each cavity has been equipped with a Priamus sensor for complete system monitoring and the application of Priamus’s process control. The 48 molded parts will be removed by a robot equipped with grippers from Gimatic, Molding Solutions’ affiliated business within Barnes.

At Arburg’s booth, Foboha will run its patented Cube Inclusive Turning Inserts (CITI) technology. Well suited for multicomponent parts where the second material is needed on both sides of a basic body, CITI will make a 3-component functional part from an 8+8+8 cavity cube mold at the K. A PP frame is first injected from the moving nozzle side, and after two 90° rotations of the cube, the component is sealed with TPE on both sides of the fixed nozzle side and a functional element made of POM is molded on the part.

Related Content

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreWhat You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreBest Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreRead Next

Answering the Sustainability Challenge with Digitalization

Attendees in the molding halls of K can count on exhibits that address two main themes: digitalization and sustainability. Digitalization in the form of smarter pieces of equipment communicating with each other and with plant personnel; and sustainability in the form of greater energy efficiency and the ability to process recycled and renewable resins.

Read MoreK 2022 Preview: Injection Molding Closes the Circle, Digitally

Because the market requires sustainability—and important component of which is the circular economy—and sustainability requires digitization, all three will be major themes at injection molding booths at K 2022.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More