All Electric and Hybrid Machines

Latest All Electric & Hybrid Machines Articles

VIEW ALLCompletely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreMachine Series Debuts for Chen Hsong

Chen Hsong has three injection molding machines in its booth, including 2-platen, hybrid and a next-generation line with improved platen and toggle design.

Read MoreNext-Generation All-Electric and Vertical Injection Molding Machines

Sodick Plustech’s VR-G and MS-G2 Series both utilize the company’s proprietary V-Line technology, separating plasticizing and injection functions, and have upgraded displays, energy efficiency, response time and more.

Read MoreAbsolute Haitian Brings Next Generation of Presses to Orlando

Absolute Haitian says Generation 5 of the servo-hydraulic Haitian and electric Zhafir machines lines emphasize efficiency, performance and intelligence.

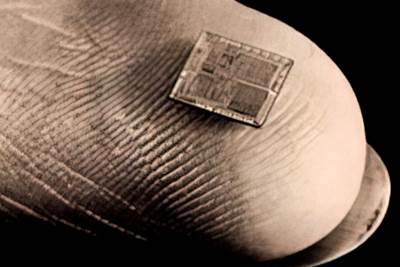

Read MoreAll-Electric IMM Advances for Packaging, Medical and LSR

NPE2024: Sumitomo SHI Demag’s show focus will be on application of all-electric injection molding machine technology for a variety of markets and components.

Read MoreIMM Cells Display Communications, Energy Measurement and Energy Recovery

NPE2024: Wittmann will feature five injection molding machines incorporating its range of robotics and auxiliaries, with all products employing industry 4.0 communications, energy measurement and a brand-new red color.

Read MoreLatest All Electric & Hybrid Machines News And Updates

Slimmer All-Electric Press Debuts

A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.

Read MoreUpdated Control, Cooling Water Distribution, Electromechanical Ejector and Injection

NPE2024: Boy’s U.S. subsidiary marks its 50th anniversary in Orlando with six machines and U.S. intros for the Procan ALPHA 6 control, and hybrid ejectors and injection units.

Read MoreMidtonnage Hybrid Range With Compact Footprint Launches

NPE2024: Milacron has the global launch of its new M-Series injection molding machine line featuring a large clamp stroke as standard in a line of midtonnage, compact-footprint machines.

Read MoreHybrid Press Runs Larger Tools at Lower Tonnages

NPE2024: Nissei’s compact FWX Series combines a novel clamp design, low-pressure molding technology, and greater platen and tiebar spacing to enable large molds to run on lower tonnages.

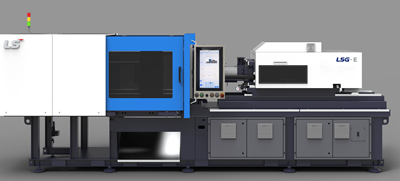

Read MoreNew Hybrid, All-Electric and Vertical Injection Molding Machines

NPE2024: In addition to new machines, LS Mtron will also launch a new 18-inch multitouch controller from Keba.

Read MoreAll-Electric Press Gets U.S. Debut

NPE2024: For the first time, Arburg will make a global premier of a machine outside Germany with the new Allrounder 720 E Golden Electric among its 13 exhibits — seven in its own booth — in Orlando.

Read MoreFeatured Posts

Custom Injection Molder Plugs into All Electric Machines

Formerly a showroom for early-aughts-era Van Dorn hydraulics, the newest additions to Drummond Industries’ transforming fleet are all-electric Niigata injection molding machines.

Read MoreWord Games: What’s a ‘Hybrid’?

Any molder will tell you there’s a difference in working with electric vs. hydraulic drives. Servohydraulic is still hydraulic; a hybrid machine is something different. Imprecise use of terms causes needless confusion.

Read More50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read More50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

Read MoreInjection Molding: Faster, Smarter, More Efficient Machines Tackle Sustainable Molding at K 2019

Blazing speed plus shrinking energy consumption supported the “green” theme at the big show. Smarter controls and growing connectivity were another key focus.

Read MoreSpeed and Flexibility Help Molder, Moldmaker Fill a Niche in Product Development

Quotes in hours, parts and molds in days—Xcentric Mold & Engineering brings prototype speed to production molding and moldmaking.

Read More