3D Printing, Silicon Valley Style

Carbon’s technology seeks to disrupt the 3D-printing industry for good.

It’s well-known that Silicon Valley is the home of new technology and advancements. So it makes sense to locate a new, innovative company that could push 3D printing (aka additive manufacturing) beyond prototyping in the same locale as creators of other technologies that are helping to shape the world’s future.

Silicon Valley-based Carbon focuses on producing parts in industrial volumes. In fact, one of the company’s slogans is, “Stop prototyping, start producing.” Founded in 2013, Carbon pioneered a new additive manufacturing (AM) technology that uses light and oxygen to rapidly produce products from a pool of liquid resin.

“We're taking the best of digital from Silicon Valley and bringing innovations, material science and additive manufacturing,” says Joe DeSimone, Carbon CEO and co-founder. “Innovation comes in a lot of different ways.”

Carbon invited Plastics Technology to its headquarters in Redwood City, Calif., to learn about the company’s technology, business model and applications.

A NEW WAY OF THINKING

Joe DeSimone’s entire career has been at the intersection of science, engineering, medicine and polymers. Throughout his time in academia at the University of North Carolina and North Carolina State University, DeSimone published over 300 scientific articles and has more than 150 issued patents in his name—with another 80+ patents pending. DeSimone also previously co-founded several companies, including Micell Technologies, Bioabsorbable Vascular Solutions, and Liquidia Technologies.

While he always found 3D printing technology of interest, DeSimone says he saw limitations with the layer-by-layer approach. He believes the technology as it was didn’t have the right properties to produce a real part. In other words, it was a niche technology focused on prototyping.

Carbon co-founder and chief technology officer Alexander Ermoshkin, who also worked at Liquidia Technologies, came to DeSimone with the idea that 3D printing could be done more effectively. Working together, the two eventually got the idea for a new approach.

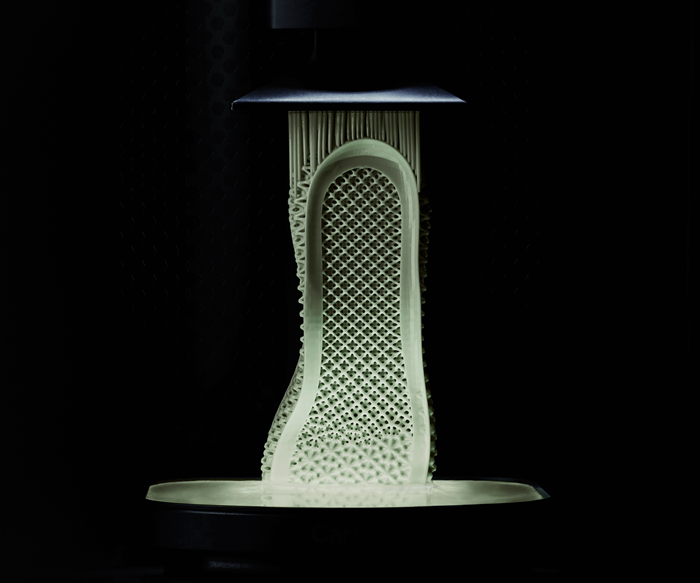

The company’s DLS (Digital Light Synthesis) technology, enabled by its CLIP (Continuous Liquid Interface Production) process, eliminates the shortcomings of conventional 3D printing by harnessing light and oxygen to rapidly produce objects from a pool of resin by literally pulling them upward continuously from the pool in a single pass, like the famous scene in Terminator 2, where the killer robot T-1000 rises from molten metal. The bottom of the growing part is cured continuously by UV light. The printed parts reportedly feature excellent mechanical properties, resolution and surface finish.

Because they are produced in a single layer, parts are said to be more isotropic in properties than 3D-printed parts produced in successive layers. Not only does Carbon’s technology produce end-use parts, but it also delivers increased speed, reportedly up to 100 times faster than other AM processes. “It is a big breakthrough in how one can make objects,” DeSimone says. After initial formation, parts require post-curing in a forced-air oven to develop their full properties.

Carbon’s 3D printing systems include the M1 printer, which was the first to use Carbon’s DLS technology, delivering layerless, high-resolution parts with high-quality surface finish and resolution. The newer M2 printer has twice the build volume, allowing for larger parts, higher throughput and lower part cost, all with the same high-resolution pixels (75 µm) and isotropic prints as Carbon’s M1 printer. The Smart Part Washer uses optimized wash protocols so that every part is cleaned consistently with minimal manual labor.

The SpeedCell is a system of connected manufacturing unit operations that enables repeatable production of end-use parts at any scale. The M Series printers and the automated Smart Part Washer are the first in a series of modular offerings that allow a wide range of industries to design, engineer, and build end-use parts with one common manufacturing workflow.

There are other aspects that set Carbon apart, too. It offers a unique subscription-based model for its 3D printing systems. The company’s approach combines connected, data-centric hardware with regular, over-the-air software updates that take place approximately every six weeks

DeSimone says the subscription model is one of the most important aspects of the company’s business approach. “Customers can get a very high-performing machine at a low price point and not worry about it becoming obsolete,” he says. “This is completely new to the 3D-printing industry. But it's also new to a lot of manufacturing equipment. Imagine having your injection molding equipment able to constantly be improved. That’s what this model allows us to do.”

If the idea of web-enabled software updates reminds you of the electric car company Tesla Motors, it’s for good reason. Craig Carlson, who now leads engineering at Carbon, was the former v.p. of software and electrical integration at Tesla. Carbon hired several other former Tesla employees, including Roy Goldman as director of software engineering. He joined Carbon in early 2015, after a little over four years of leading the software team at Tesla that was responsible for the Model S in-car displays, mobile apps and cloud-based systems.

“At Tesla, we were really aggressive about bringing connectivity to machines that people typically don't think of being connected—in that case it was cars,” Goldman says. “But we thought there is just as big an opportunity for manufacturing equipment having a lot of benefits with that kind of connectivity. We’re helping designers and engineers rethink what's possible with our technology.”

ADIDAS PARTNERSHIP

One of the biggest partnerships to date for Carbon is with adidas, Portland, Ore., which was announced in 2017. The two companies unveiled Futurecraft 4D, the first performance footwear produced with Carbon’s DLS technology.

“3D printing is one of those technologies that really can have unlimited possibilities,” DeSimone says. “We explored whether we could make a running shoe out of 3D-printed material that really works. And it does.”

Carbon’s software leverages the company’s M Series printers and its wide array of programmable liquid resins to print unique lattices that can replace materials such as in-shoe midsoles. What is especially unique is Carbon’s ability to design and make tunable lattices depending on customer application needs. Engineers for the first time can 3D print multiple unique functional zones within the same monolithic part and tune the mechanical properties within each of these functional zones to the application requirements.

adidas partnered with Carbon to develop a midsole that met the performance and comfort required by serious runners. adidas was seeking a platform that would enable it to tune cushioning properties throughout the shoe and ultimately provide bespoke athletic footwear. Carbon’s DLS process allows adidas to precisely address the needs of each athlete in regard to movement, cushioning, stability and comfort with one single component. adidas plans for more than 100,000 pairs by end of 2018.

The digitized footwear-component creation process eliminates the need for traditional prototyping or molding. Carbon’s technology enabled adidas to execute more than 50 design iterations. Engineers from both companies collaborated closely and tested nearly 150 resin iterations.

The final midsole material is made from a blend of UV-curable resin and polyurethane. It is a stiff elastomer that can be printed in a lattice structure to create a high-performance midsole.

Other potential applications with this technology include bike seats, orthopedic pads and headsets. “That's going to change how we create products and certainly how consumers experience them,” DeSimone says. “I would say this is just the very beginning.”

SPEED OF INNOVATION

Vitamix in Cleveland produces blending equipment for home and commercial use. Vitamix recently partnered with Carbon to redesign a specialized nozzle used in commercial settings. The old nozzle design was intended to be assembled from six injection-molded parts.

Carbon produced an optimized Vitamix nozzle in a single 3D-printed part with no multi-part assembly. Empowered by Carbon’s digital manufacturing capabilities that allow for rapid design validation as well as final manufacturability validation, product engineers produced six to seven nozzle design iterations within only four weeks. Using the injection molding approach, a single design iteration and resulting tooling could have taken eight to 10 weeks.

“The constraints of injection molding, I would argue, are the weight on the economy of the world of developing new products—because you can't do things digitally,” DeSimone says “You can't move very quickly. There are long lead times. And high tooling costs can put a program at risk.”

Carbon exhibited at NPE2018 and Phil DeSimone, the company’s co-founder and v.p. of business development (and Joe’s son), said that the show allowed Carbon to get in front of molders to position its technology “as another tool in their toolbox” versus a replacement for traditional molding. “We try to connect with them on a product they wouldn’t have done otherwise. For us, what we need to do is find that first component,” he said.

Carbon has hired several employees who had previously worked in injection molding. Joe DeSimone says the company is eager to take the learnings from injection molding and help educate molders on how to redesign for additive. “It’s a complement to what they already do—all those jobs they turned down because the potential customer wants the parts sooner or they only want 100 parts and it’s not worth cutting a tool, right? They don’t have to say no to those jobs anymore. This gives them the capability to complement their existing infrastructure with a balance between analog and digital in this new frontier.”

Related Content

Additive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.

Read More3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

Read MoreMedical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.

Read More420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's Additive Manufacturing Technology is Designed for Precision Tooling

Read MoreRead Next

New 3D Printers at NYC Show

Affordability, speed, and improved mechanical properties appeal to early adopters.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More