All-Nanolayer Disk Die Pushes Blown Film Layer Limits

Patented die aims to extend blown film layer limits beyond the current nine- and 11-layer standards currently considered high-tech.

BBS Corp. is continuing to develop die technology to produce nanolayer blown film. It’s the second of two recent developments that could push film extruders to investigate processing technologies beyond the nine- and 11-layer structures that are currently considered the “top end” of the industry. As reported in the last issue (see Close-Up on Technology) Italian machine builder GAP developed technology utilizing three feedblocks and an annular die to produce 27-microlayer blown film.

Nanolayer technology has gained a foothold in cast film—notably for stretch applications—due largely to the efforts of Cloeren Incorporated, which developed feedblock technology enabling processors to produce film with dozens of layers.

BBS, based in Spartanburg, S.C., is run by Hank Schirmer, who retired from Cryovac Corp. (now Sealed Air) as the director of new technology. Schirmer holds more than 100 patents, the latest of which was granted last December for an all-nanolayer die. This patent is an extension of the layer-sequence repeater (LSR) die technology Schirmer invented about 20 years ago. That technology has since been sold by BBS to a global film producer that makes medical bags.

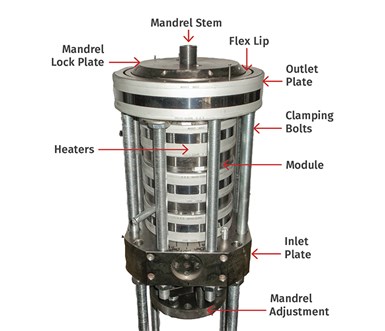

New nanolayer dies are available in 1X (shown here) and 2X (higher output) designs. Note the external clamping bolts, designed to prevent leakage.

Modules, Cells, Disks

As Schirmer explains, BBS’s all-nanolayer die is composed of modules, each of which is in turn composed of cells that take melt from two places 180° apart to produce better symmetry for each layer. This, he maintains, results in more uniform thickness control of each nanolayer. Each cell is composed of nine or more very thin disks that are pinned together. “These disks are the building blocks that can change the geometry for each cell, more or less like a Lego set,” Schirmer states. “This, in turn, accommodates each plastic accordingly and can be changed according to the rheology of each resin for best flow optimizing.”

Schirmer explains further: “The all-nanolayer die will give you whatever you want by virtue of the modular setup of cells and disks. No longer do we need to describe this coextrusion die by the number of layers that it makes. You simply assemble the modules to give you what you desire—one layer, two layers or 50 to 100 layers—knowing that each layer is as uniform in thickness as you can get it. The die does all the melt directing, so you just need one extruder for each material used. Whether it is three layers or 50, the die does it all.”

The most recent patent covers the module. This is an often-complicated assembly of precisely laser-cut and hand-finished disks. The particular way the module is assembled defines the film structure. There can be more than one module within a die assembly.

“The die does all the melt directing, so you just need one extruder for each material used. Whether it is three layers or 50, the die does it all.”

The new modules consist of cells, and each cell has two geometrically opposite inlets for the melt and produces two layers of either the same material or different materials. This, in turn, gives better thickness control of all the nanolayers of different materials that the die produces, Schirmer says. “Basically the module is the heart and soul of the die and defines the film quality that is produced. By changing modules, a processor will change the film structure. He can have more than one modular configuration ready to be inserted into the die at any time. This is analogous to a razor and a razor blade. The razor remains the same, but the blade is changed, and it is the blade that defines the shave.”

Shown here is a 75-nanolayer film structure of nylon 6/EVOH made on a BBS die. The layers are concentric and continuous around the circumference of the bubble. You can event count them.

Modules can be prearranged and put into an inventory of modules so that when needed they can be inserted within the die. This makes downtime shorter whenever the die needs to be cleaned or the film structure changed. “Versatility is the word here to describe it all,” Schirmer states. “The modules are also very easy to clean by heating to around 900 F or so to burn off the polymer. We simply use a wood stove for a 4-hr burn. After it cools, we simply blow out the ash and the module is ready to be used again without disassembly.”

The dies are designed with external clamping bolts. “This was done to get the highest clamping pressure so that the die doesn’t leak,” Schirmer states. “The modules get hot, but the clamping bolts remain cool. The heat causes the modules to expand, but the cool bolts really get stretched tighter than you might be able to do with a torque wrench.”

Since Schirmer introduced the LSR technology, he has had alliances with two suppliers of blown-film systems: China’s Jin Ming and Canada’s Alpha Marathon. Jin Ming tested a high-output LSR die, which BBS sold to a processor in France. Alpha Marathon sold a line equipped with Schirmer’s die to an Asian processor. BBS has also sold several dies to a processor based in Europe, and has sold dies to two U.S. processors. BBS now operates independently.

Six-extruder line at BBS’ lab in Spartanburg is set up to make 52-nanolayer film.

New nanolayer dies are available in 1X and 2X sizes. The 1X dies have a maximum annulus of 8 in. and can accommodate outputs up to 300 lb/hr. The 2X die has a maximum annulus of 18 in. and can operate on lines running above 1000 lb/hr.

BBS has a film lab in Spartanburg for customer trials. “We can show them how to assemble modules from cells and cells from disks,” states Schirmer. “This is simplified with the use of a simple CAD computer program, because you can move things around on the viewing screen and keep track of what has been done. Basically, we are available to consult with clients at every step of the way from microscopy to film production in their plant.”

Schirmer is filing additional patents for further improvements to the die. These involve making more symmetrical nanolayers and reducing the number of extruders needed to make complex structures. “One patent pending is for an entirely new blown film line with fewer extruders, designed to make a wide array of high-quality films featuring these new dies with all the bells and whistles,” he says. That new line is now in the BBS lab in Spartanburg.

Related Content

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreAutomotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read MoreHow Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

Read MoreRead Next

Novel Line Produces 27-Microlayer Blown Film

Italian machine builder unveils blown film system that relies on feedblocks—far more common in flat-die processing—to yield thin yet strong film.

Read MoreWhat You Need to Know to Make World-Class Stretch Film

Advances in materials, feedblock/die technologies, and winding can help processors develop more sophisticated cast-stretch products.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=300;quality=90)