Best Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Producing plastics parts with undercuts presents distinct challenges for molders. Undercuts are protrusions or recessions in a part that prevent the mold, after the part is formed, from sliding away along the parting direction. These features inhibit the direct removal of the core, and as a result, generally necessitate using an additional mold piece, such as a side-core or an internal core lifter, to form the shape.

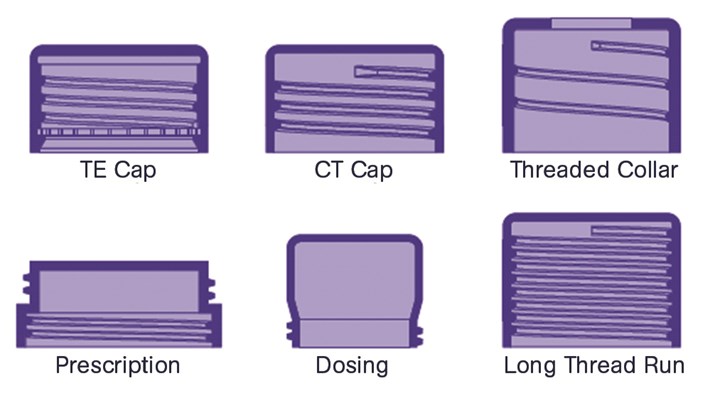

Six examples of part designs with undercuts: a TE cap, CT cap, threaded collar, prescription, dosing, and long thread run design.

Undercut designs are often used to create threaded parts, such as screw-on bottle caps, snap-on products such as lipstick containers, and a variety of consumer, medical, automotive, and other products. Threaded caps illustrate well the complexities associated with undercuts. After the cap is formed, the threads of the part and the threads of the core are intermeshed and must be disengaged before the core can be pulled out and the cap removed from the mold.

Molders have developed a variety of methods for molding undercut or threaded parts—some as simple as unscrewing the part by hand or machining the undercuts in a separate operation—that range widely in cost-effectiveness and efficiency. This article will present some of the recent technology advancements that give molders better, more cost-efficient methods of producing undercut or threaded parts.

UNSCREWING MOLD MECHANISMS

Two of the most common methods for dealing with threaded parts are by jumping threads or installing unscrewing mechanisms. Occasionally, if the material is flexible enough, a molder can simply pull out the core or strip the part, jumping the threads over each other. If this isn’t an option, unscrewing mechanisms built into the mold can unscrew the part from the core as a secondary action.

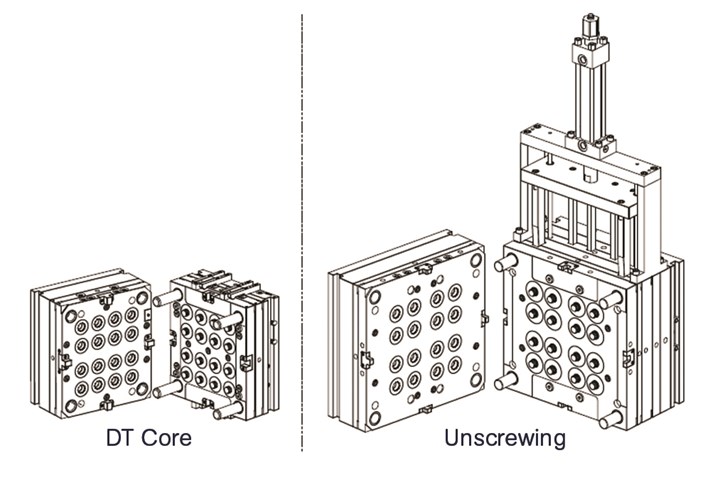

Unscrewing molds are highly complex, requiring considerable technical savvy to build and maintain. Dovetail collapsible-core molds (left) are simpler and more compact.

Unscrewing molds are among the most complex of all injection molds, requiring considerable technical savvy to build and maintain. They are usually built for many years of production and are considered a long-term investment for producing high-volume parts. Unscrewing technology has evolved considerably, but it still has a significant number of limitations. It demands frequent maintenance for issues such as broken rollers, damaged racks, and water and oil leaks. Part quality issues such as scuffing, ovality, flash, and grease contamination can arise as well.

COLLAPSIBLE CORES

One technology that has expanded the capabilities of undercut molding more than any other is the collapsible core. Rather than jumping the threads or mechanically unscrewing the parts, flexing steel collapsible cores function by collapsing radially inward during the normal mold sequence. They eliminate secondary operations and complex coring approaches while providing dramatic cycle-time reductions—often as much as 30% faster than with unscrewing mechanisms.

The segments of a collapsible core are attached to the ejector plate, while its tapered inner center pin is attached to the back of the mold. When the mold opens, the threaded outer core collapses as the ejector plate moves forward. Incorporating only three moving parts, which utilize conventional mold movements, a collapsible core enables part designs that previously would have been considered impossible to mold.

Collapsible cores are compatible with other mold components, such as two -stage ejectors and internal latch locks. These products enable positive control of both the stroke sequence and distance in two-stage ejection and of mold-plate latching operation.

•Two-stage ejectors: These adapt to a number of mold-base sizes and plate thicknesses and are available in two ejection sequences: top last and bottom last. The stroke range for each ejection stage is fixed in a simple procedure, and it cannot be tampered with or accidentally changed once installed. With internally installed components, the two-stage ejector avoids interference with waterline connectors and externally mounted components.

•Internal latch lock: This allows measured control of the mold-plate opening sequence on mold bases with stripper plates. One group of plates can be latched together while the first parting line opens. After a predetermined amount of travel, the latch lock releases the latched plates for the remaining parting line or lines to open. Like the two-stage ejector, once installed, the internal latch lock cannot be accidentally changed and does not interfere with waterline connectors or externally mounted components.

The function of the collapsing core also permits threads to stop at any point along the molded length; threads need not run out to the top of the core, as with unscrewing molds. If a seal is required in the top of the closure, an undercut can often be molded into the part to hold such a seal in place.

The collapsing action also permits a longer threaded area to be formed, without adding to the cycle time or requiring long rack-and-pinion mechanisms. In addition to threads, other configurations such as dimples, cut-outs, or protrusions beyond the capabilities of unscrewing molds can be successfully molded.

COLLAPSIBLE MINI-CORES

Collapsible cores have many advantages, but sometimes they’re just too large for the application. That’s when molders turn to collapsible mini-cores. These broaden the applications of collapsible-core molds to closures as small as 10.8 mm diam. Due to the smaller diameters involved, these mini-cores employ three larger collapsing segments combined with three narrow, noncollapsing blades, which are an integral part of the center pin. As a result, up to 80% full threads or undercuts can be molded.

Collapsible mini-cores provide many of the advantages of collapsible cores for parts as small as 10.8 mm diam.

CHALLENGES OF COLLAPSIBLE CORES

The collapsible core is designed to collapse independently when the center pin is withdrawn. The fit between segments is controlled to permit flash-free molding, which means the location of the core on its pin is critical. The distance between the back of the core flange and the front of the center-pin flange, known as head space, must be precisely maintained. Otherwise, inaccuracies in head space will produce unsatisfactory operation and possibly cause permanent damage to the core.

The collapsible core is designed to operate without benefit of lubrication. While it’s possible to treat the core with an alloying process for wear reduction and corrosion resistance, plating the core is not recommended.

The individual segments of the collapsible core have a self-cleaning action that will tend to carry any dirt or deposits to the outer surface of the collapsing core. As a result, the first 50 to 100 shots may show foreign matter deposits on the inside of the molded part. Prior to final assembly of the mold, the core should be thoroughly degreased and cleaned. It’s usually a good idea to lightly wipe the tapered end of the center pin with grease or PTFE lubricant to help break it in.

You should also make sure that the collapsing core is free to turn when installed in the ejector plate. This slight play will permit the core flange to “float” slightly, helping it find its own center and equalizing wear on the center pin. To completely collapse the core, the center pin must be withdrawn a specified amount. The ejector stroke varies for different models of the core.

Stripper-plate actuation must be sequenced so that the cylinders have returned the stripper plate before the ejector plate has returned. This will avoid interference of the stripper ring with the core and possible core damage. Collapsible cores are individually fitted to a matching numbered pin, and cannot be interchanged.

Collapsible cores and mini-cores have set the bar high for efficiency and cost savings. But even these technologies have room for engineering progress. A recently improved version of this technology, the Dovetail Collapsible Core, enhances the strength and function of the traditional design.

DOVETAIL COLLAPSIBLE CORES

Dovetail collapsible cores provide the most compact and simplest way to mold challenging internal undercut features. With a mechanical means for collapsing segments, the Dovetail core has added versatility to handle a larger range of diameters and undercut depths.

Dovetail collapsible cores provide the most compact and simple way to mold challenging internal undercut features.

Molders sometimes hesitate to use standard collapsible cores in part because the product’s design uses steel flexing segments that are all integral to each other. If, for example, a machine clamps up on a part, the segments of the conventional collapsible core may be damaged or broken. Although the root cause is improper molding operation or mold design, this type of error creates an undeserved negative reputation for flexing steel collapsing cores.

Because of their strength, dovetail joints are commonly used to lock components together in woodworking and other industries. Similarly, Dovetail collapsible cores are much stronger than their conventional counterparts. Standard collapsible cores use a tube of steel slotted into 12 individual segments, while the Dovetail uses six independent segments, which are larger, stronger, and easily repaired if necessary.

Conventional collapsible cores work well in the B-half of the mold but can create design issues in the A-half. The segmented design of the Dovetail enables it to work equally well in either half of the mold. This means a molder can use fewer, smaller mold plates and a smaller molding machine for higher cost savings.

Dovetail collapsible cores also enable shutoffs, both front and side. This is a major advantage for moldmakers compared with conventional collapsible cores, which often require part-design modifications to deal with collapsing segments or mold shutoffs. However, both styles of collapsible cores can be used to mold protrusions or cut-outs into the side wall of a part.

Straightforward actuation of the Dovetail collapsible core enables manufacturers to design and build a mold that requires only “mold open/mold shut” commands to operate. In most cases, there is no need for special core-pull circuits or even the common ejector-plate sequence. The potential cycle-time reduction is enormous. Dovetail collapsible cores also incorporate a patent-pending quick-lock system that enables molders to quickly remove the assembly from the mold without removing the mold from the machine.

Another prominent benefit of dovetail design is that moldmakers can use a standard fixture to grind the thread onto the outer diameter of the core. This isn’t an option with conventional versions, which require a mold builder to either buy or build a special grinding ring.

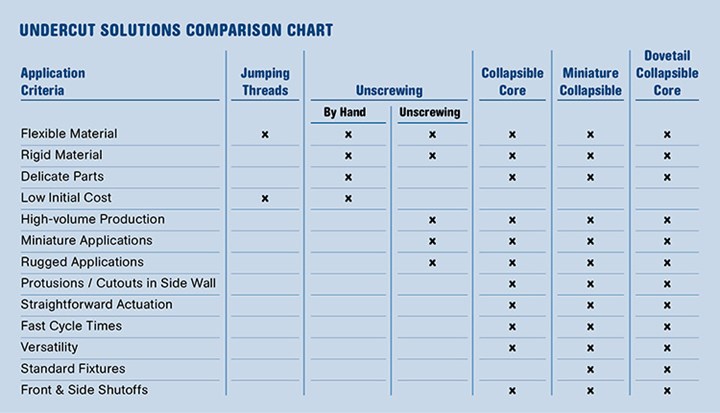

Comparison of undercut parts solutions.

Undercut parts present many challenges to designers and molders, but technology is always evolving to meet them. While some methods for molding undercuts are tried and true, they might not always provide the cost savings or efficiencies of more advanced technologies. Dovetail collapsible cores have proven to be a great solution for a variety of applications – improving cycle time, cost savings and reliability. This product is available from DME.

Related Content

Impacts of Auto’s Switch to Sustainability

Of all the trends you can see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Read More3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

Read MoreThin, High-Performance Nylon/PE Barrier Film for Thermoformed Packaging

Südpack’s Multifol Extreme film is well suited for greasy, protein-rich and frozen foods

Read MorePHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreRead Next

How to Demold Parts Faster, With Less Stress and Surface Defects

You may need to unlearn what you always thought was the right way to get parts out of an injection mold.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More