CJ Biomaterials Launched First Consumer Brand Cosmetic Packaging Application

Olive Young’s Wakemake cushion container made of PHA and PLA

In later November, 2022, we reported that CJ Biomaterials, Inc., (U.S. office in Woburn, Mass.), a division of South Korea-based CJ CheilJedang and leading producer of proprietary PHA (polyhydroxyalkanoate), and NatureWorks, the leading global producer of PLA (polylactic acid), had signed a Master Collaboration Agreement (MCA) for the development of sustainable materials solutions based on CJ Biomaterials’ Phact Biodegradable Polymers and NatureWorks’ Ingeo biopolymers in applications ranging from compostable food packaging and food serviceware to personal care, films, and other end products.

CJ Biomaterials wrapped up 2022 by announcing that it had developed its first consumer brand application using its amorphous PHA (aPHA) technology in combination with PLA and in direct competition with ABS. This is a new cosmetic case sold under the private brand Wakemake from CJ Olive Young, a market-leading health and beauty retail chain in Korea with a global network across 150 countries.

The Wakeme Water Velvet Vegan Cushion uses vegan cosmetic ingredients along with the new eco-friendly packaging. PLA has experienced significant growth as a biobased material in a broad range of finished product applications and is currently the most widely used industrial compostable material in the world, but it has certain limitations.

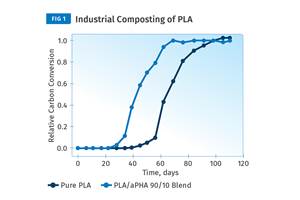

Blending amorphous PHA in PLA has been shown to lead to significant improvements in the mechanical properties of PLA, such as toughness and ductility leading to improved impact resistance and the creation of elegant shapes. As previously reported, CJ Biomaterials’ Phact amorphous PHA is a softer, more rubbery version of PHA that offers fundamentally different performance characteristics than the crystalline or semi-crystalline forms that currently dominate the PHA market.

The 100% bio-sourced solution of amorphous PHA and PLA materials were applied to the entire outside of the Wakemake container, replacing ABS. Some developed countries and leading cosmetic brands are actively making efforts to replace petroleum-based and non-biodegradable ABS that is currently widely used in cosmetic containers.

Said Seung-Jin Lee, head of CJ CheilJedang’s biomaterials business. “This is an important milestone for CJ Biomaterials, and we expect that the application of biobased materials in the consumer goods market will expand beyond the release of the Wakemake cushion. We will widely promote the use of PHA in various markets, as it is an eco-friendly material that is effective for industrial-scale use. We are proud that our PHA products—which are derived from nature and return to nature—are helping to meet the growing demands from brands and consumers for more environmentally friendly products.”

In early 2022, the company announced commercial-scale production of PHA following the inauguration of its production facility in Pasuruan, Indonesia, becoming the only company in the world that can produce aPHA at scale, which includes CJ Biomaterials’ first product under its new Phact brand, named Phact A1000P. The company also expanded its biomaterials business by establishing relationships with global organizations, including NatureWorks, as noted above, as well as health & hygiene companyYuhan-Kimberly, the Accor hotel chain for which the two companies will work jointly to replace all single-use plastic amenities used by Accor, and the makeup brand Banilla Co., which plans to launch cosmetics with containers made from bio-sourced materials in early 2023.

Related Content

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read More50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

Read More50 Years...600 Issues...and Still Counting

Matt Naitove marks his first half-century in plastics reporting, with a few of his favorite headlines.

Read MoreBlend Amorphous PHA with PLA to Improve injection Molded Part Properties

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More (2).jpg;maxWidth=970;quality=90)

(2).jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)