Permanent Decoration for Polyolefin Injection Molded Parts

Close-Up: Decorating

Low surface energy of nonpolar plastics like PE and PP has made them a challenge to decorate, but a new technology seeks to change that.

Polyfuze Graphics Corp., Clarkdale, Ariz., is the very recent spin-off of Mold In Graphic Systems (MIGS), which initially developed permanent graphics suited for rotationally molded polyethylene (PE) parts. MIGS started with in-mold graphics before moving to a version applied post-mold.

The company sensed a market opportunity for a post-mold or “mold-on” graphic in injection molding and created its Polyfuze technology to fulfill that need for polyolefin parts. Since its launch, Polyfuze, which defies traditional plastics decorating definitions, has occasionally led to some confusion. Jason Brownell, Polyfuze v.p., cites an example from the recent NPE2015 show in Orlando:

“We had a gentlemen standing at our booth, and I asked him, ‘Are you trying to figure out what we do?’ He said, ‘No, I know what you guys do.’ I said, ‘OK,’ and he says, ‘So you guys are heat transfer?’

‘Nope.’

‘So, it’s like hot-stamp foil?’

‘Nope.’

“So he says, ‘All right, what do you guys do?’”

The show visitor’s confusion likely came from the fact that Polyfuze utilizes traditional hot-stamp or heat-transfer equipment, but that’s where its similarities to those decorating techniques end.

FUSING VS. STICKING

“Most decorating technologies out there for PE and PP try to stick, try to adhere,” Brownell says. “We don’t stick at all.” Brownell explains that whereas a heat transfer’s construction consists of an adhesive layer, inks, and a clear coat to protect those inks, a Polyfuze graphic is essentially the carrier film, on which the graphic is printed, and the graphic itself, which is pigmented plastic that’s chemically compatible with polyolefins.

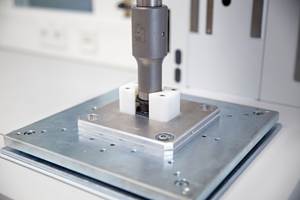

The differences between Polyfuze and heat transfer or hot stamping, despite using the same equipment, don’t end there. Polyfuze is a high-heat/low-pressure process. The machine is set to 550 F to achieve a temperature of 450 F at the die face. Polyfuze then needs only about 75 psi of pressure to decorate a part, versus roughly 500 psi for heat transfer and 400 psi for hot stamping.

“We’re not trying to push two materials together to make them stick; we’re literally just melting them together,” Brownell says. “So as long as you make contact, it’s the heat that’s doing all the work and not so much the pressure.”

The fact that Polyfuze works specifically with polyolefins—a material class that historically has not taken well to decorating—has opened up some new application areas. “I did a presentation in Detroit,” Brownell says, “and a person approached and said, ‘You know why the automotive industry doesn’t use a whole lot of olefin materials? Because we’ve never been able to decorate them.’”

In colors, Polyfuze offers matching for custom hues, plus four-color CMYK, Pantone Matching System, RAL charts, or ANSI charts for safety colors. It can also use half-tones to create gradient patterns.

A MOLDER'S EXPERIENCE

Challenge Plastics Products Inc., Edinburgh, Ind., a custom molder that also makes some proprietary products, had been out of the decorating business for 10 years, when a client asked it to add 2 x 1 in. heat-transfer labels to a PP lid, according to Anne Davis, v.p. of business development. The firm had used only hot stamping in the past.

“We were starting from scratch,” Davis says. “No equipment, no experience applying heat transfers. We didn’t even have a source for heat transfers.” Her research eventually led her to MIGS and Polyfuze and away from previous technologies. “While I was out there looking for heat-transfer labels, I stumbled onto Polyfuze’s technology, which was actually a much better fit for our product.”

Davis said Polyfuze graphics offer longer life and better stability in the outdoor environment. Challenge Plastics also did a price comparison and learned that Polyfuze would be a more attractive option on a startup product, as well as being competitive at high volumes.

Challenge Plastics has been running this decorating application since December, with the help of Polyfuze and Trekk Equipment Group, Pacific, Mo., which supplied the machine.

Challenge Plastics is now thinking about more opportunities to use Polyfuze. “Our business is somewhat targeted at doing private labeling,” Davis says, “so it’s becoming more important for us to have decorating capability. ”

Polyfuze will soon become a separate entity from MIGS and will move into its own production facility. General Manager Marty Mares says the company is ready to make more converts, including in structural foam, where it’s just now making inroads. Mares says: “When someone says they have a permanent decorating solution for polyolefins, there’s a certain amount of skepticism. Lots of people have made that claim in the past, but there are some big differences that set us apart from other technologies. There’s that light-bulb moment when they realize it’s not about sticking, it’s literally fusing together.”

Related Content

SD Polymers: 'One-Stop Solution for Mechanical Recycling'

‘Passionate’ recycler invests in people and technology to meet commitment to innovative, sustainable solutions for its processor customers.

Read MoreCan Plastic Recyclates be Welded Ultrasonically?

What is possible with ultrasound? Will the result with recycled plastics material actually be worse than with standard material? Do we have to adapt our technology?

Read MoreNext-Generation Workhorse Ultrasonic Welding Machines

NPE 2024: Rinco Ultrasonics’ line of standard ultrasonic welding machines significantly upgraded.

Read MoreNext-Generation Fully Electric Ultrasonic Welding System

NPE 2024: Rinco new eMotion servo-driven machine is available in 20 kHZ and 35 kHz frequencies.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read More