The K is a truly global show, largely immune from regional political and economical whims of the moment, but the European energy crisis sparked by Russia’s invasion of Ukraine was top-of-mind for injection molding machine makers at K 2022. “Energy-efficient solutions are vital for Europe’s survival,” Engel stated plainly in its show release, adding, “in Eastern Europe, extremely high energy prices are challenging the existence of many companies.”

Electricity prices were up in 22 European Union (EU) member states last year, according to EU Eurostat, with the largest increases in the Czech Republic (+62%), Latvia (+59%) and Denmark (+57%). And the United Nations released a report on Dec. 2 entitled, “Energy crisis poses threat to Europe’s industrial sector.”

Arburg’s Managing Partner Michael Hehl framed the current moment by reflecting back on K 2019 and noting that three years back, who could have predicted the Covid 19 pandemic, war in Ukraine and “drastically rising material and energy prices.” Guido Frohnhaus, Arburg’s managing director for technology and engineering, added that energy efficiency is “a particularly topical issue, which is rapidly gaining in importance due to the huge increase in energy costs.”

Fortunately for molders everywhere squeezed by utility bills, greater energy efficiency has long been a focus for machine suppliers. Many of the advances announced at the show, whether directly or indirectly, sought to maximize machine output per kilowatt-hour. (Previous K 2022 injection molding coverage can be found here and here).

Duo Debut

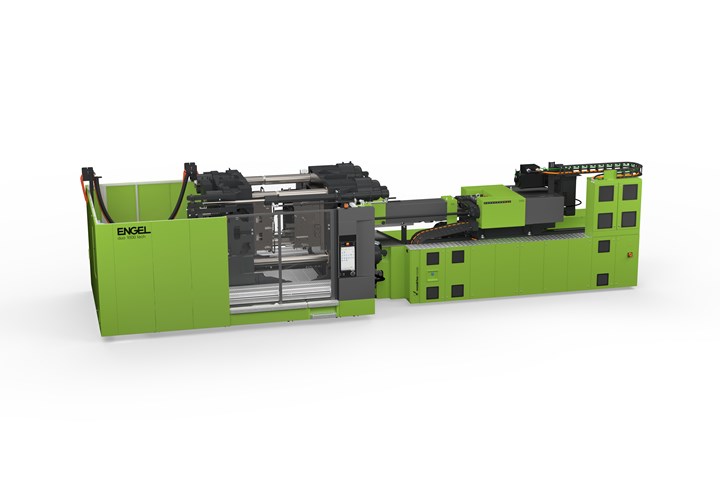

Boasting greater mold mounting space and therefore the ability for more output from the same footprint with less energy consumption, Engel’s newly revised duo tech series of dual-platen presses has added two new clamp sizes, bringing the range to 35 models from 385 to 5600 tons. Compared with the previous duo series, the clamp sizes have been redistributed and supplemented by more wide-platen versions. The injection unit has also been updated with 25% greater injection and plasticating capacity.

An Engel duo 1000 tech press molded this PP door panel for Faurecia using the foammelt process and Trexel technology, reducing weight by 18%. (Photo: Plastics Technology)

Applying smart assistance technology similar to that used to optimize acceleration of its viper linear robots, Engel also introduced iQ motion control to accelerate clamp movements, saying it has reduced dry-cycle times by about 10%. Noting that the moving platen doesn’t just open and close but moves along individual motion points, Engel says the iQ motion control software computes the optimum acceleration for the matching machine settings of each individual phase. The calculations are based on the configured mold stroke, clamp force and mold weight, with iQ motion control optimizing the acceleration phases automatically at the push of a button. At the show, Engel displayed this feature on an all-electric e-speed machine molding 125-ml round containers from rPET in a four-cavity mold. Applying iQ motion control reduced the time required for mold movements from 1.27 sec to 1.12 sec, with a total cycle-time reduction of 5%.

The new duo tech can accommodate bigger tools within the same footprint with a shorter dry cycle. (Photo: Engel)

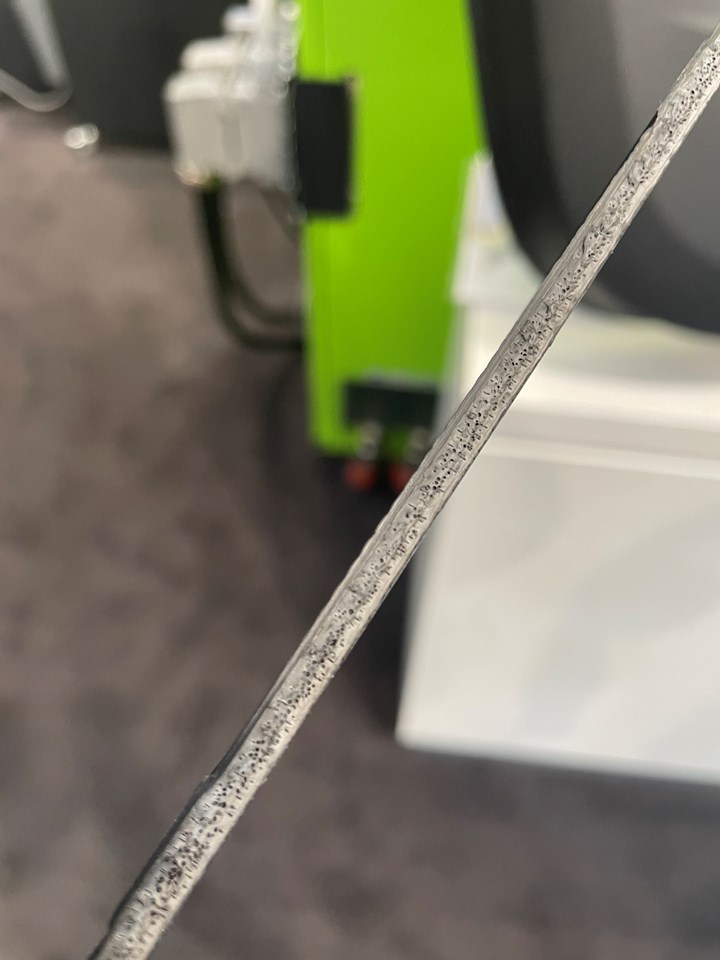

Inline Compounding

Building on its long-running injection molding compounder (IMC), which combines a twin-screw extruder and injection molding machine for inline compounding of larger parts (shot weights of at least 1500 g), KraussMaffei introduced what it called direct compounding injection molding (DCIM), piggybacking a single-screw extruder on a GX series hydraulic press for shot weights from 50 to 2000 g. At K, this machine combined PP staple-fiber fleece from FFP2 face masks; shredded HDPE from logistics packaging; and HDPE blow molding scrap to mold a five-piece collapsible crate in a 35-sec cycle. Helping combat not only high energy prices, but resin scarcity and rising prices, the DCIM reportedly can deliver cost savings up to 50% by allowing molders to process internal scrap or clean external waste into new parts. Noting that the three disparate scrap materials in this demonstration had widely varying melt-volume ranges, KM said a special long screw (30:1 L/D) was utilized in the DCIM extruder. KM says DCIM is certified by the German Institute of Sustainability for savings of 0.8 kWh/kg of plastic processed.

In the DCIM, the extruder is installed in a piggyback position directly over the injection unit of a standard hydraulic machine. (Photo: KraussMaffei)

Related Content

Spinning Straw Into Gold With Chemical Upcycling

Upcycling diverts waste by converting it to high value materials.

Read MoreK 2022 Additives & Materials: Sustainability in the Lead

Nearly all of the new additives highlighted at the big show are aimed at enhancing recyclability of commodity resins and some volume engineering resins such as nylon and PC. A few new materials, on which we had not previously reported, also surfaced at K 2022.

Read MoreHow Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

Read MoreK 2022: ‘We’ve Been Waiting 40 Years!’

With sustainability top-of-mind in the plastics industry, this was a ground-breaking show for builders of recycling equipment. It also prompted new thinking in thinwall injection molding.

Read MoreRead Next

Answering the Sustainability Challenge with Digitalization

Attendees in the molding halls of K can count on exhibits that address two main themes: digitalization and sustainability. Digitalization in the form of smarter pieces of equipment communicating with each other and with plant personnel; and sustainability in the form of greater energy efficiency and the ability to process recycled and renewable resins.

Read MoreK 2022 Preview: Injection Molding Closes the Circle, Digitally

Because the market requires sustainability—and important component of which is the circular economy—and sustainability requires digitization, all three will be major themes at injection molding booths at K 2022.

Read More

.png;maxWidth=300;quality=90)

(2).jpg;maxWidth=300;quality=90)