ERP Software: New Ways to Find Your Data, Lower-Cost Entry for Small Plants

The past year has seen several product upgrades and new features in the EnterpriseIQ enterprise resource planning (ERP) software system from IQMS, Paso Robles, Calif.

The past year has seen several product upgrades and new features in the EnterpriseIQ enterprise resource planning (ERP) software system from IQMS, Paso Robles, Calif. These range from a new web-based portal that provides customized single-point access to all ERP data for single or multiple plants to affordable entry-level systems for small plants. IQMS also introduced keyword searchability of all ERP data, greater traceability for assembly manufacturers and compounders, wireless ERP networking in the plant, and new abilities to tie in conveying, packing, and other product-handling equipment. All these new features will be displayed and/or discussed at the NPE show in Chicago this month.

WEB-BASED ERP PORTAL

At the end of 2008, IQMS introduced the Smart Page internet portal to EnterpriseIQ. Smart Page provides full access to ERP areas of single or multiple plants—quality, manufacturing, engineering, accounting, customer services, maintenance, etc.—from almost anywhere. Each user creates a unique customized workspace displaying the information appropriate to that person’s role. One person may have multiple alternate workspaces if he or she wears different “hats,” such as CEO, production director, and financial officer.

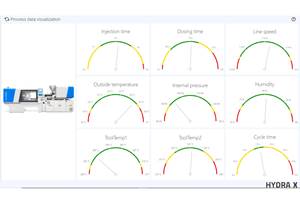

Smart Page provides a number of ways to view ERP data, which can be filtered by company, plant, or individual machine or manufacturing cell. Unlimited numbers of charts and graphs with drill-down capability can be incorporated in a workspace. Real-time production monitoring is facilitated by easy-to-read “speedometers” that provide instant shop-floor data from local or remote business units. Users can create speedometers for a customized selection of key performance indicators, ranging from machine utilization, cycle-time efficiency, scrap rate, and unscheduled downtime to financial variables like inventory turnover or rate of new orders coming in. Users can click on any speedometer gauge to obtain more detail. Gauges can even be programmed to send an e-mail alarm message if results fall outside a preset range.

So-called “tree maps” display hierarchical (tree-structured) data as a set of nested rectangles. Each branch of a tree is given a rectangle, which is then tiled with smaller rectangles representing sub-branches. Branches end in “leaf node” rectangles sized in proportion to a specified dimension of the data. Leaf nodes can also be colored to show a dimension of the data. As shown in the accompanying rejects tree map, the colors and rectangle sizes work like a Pareto chart to help a user prioritize troubleshooting. The largest blocks, which are also colored red, represent jobs that generate the most rejects and that logically should be addressed first.

Smart Page also includes a flow-chart tool for creating process flow diagrams. It can be used, for example, to generate Standard Operating Procedures for QC departments or for approvals of purchase orders, work orders, etc.

Smart Page provides each user with individualized workflow processing by means of a “My Workflow” page that shows on a single screen all pending approvals (engineering change orders, corrective action reports, etc.) for that user to act on and other pending tasks such as assembling staff for a meeting or expecting a report that is due from another department.

A brand-new feature in Smart Page is called SmartSearch. This is a text search function, with a familiar “Google-style” interface, that can find instances of that text string (customer name, product name, raw material, etc.) anywhere in the EnterpriseIQ database and display them in a typical search-engine format. “It can scan hundreds of thousands of records in just seconds,” says Randy Flamm, president and founder of IQMS. What he calls “fuzzy searching” accommodates slight misspellings and variants of search terms. What’s more, the search can be limited to any area of the database, such as manufacturing, quality, sales, and so forth.

Smart Page and SmartSearch are available at no extra cost and as a free upgrade to existing EnterpriseIQ customers.

SMALL-BUSINESS PACKAGE

With its new Small Business version of EnterpriseIQ, IQMS just made it easier for smaller firms to acquire an ERP system. A firm with around eight or nine machines can buy a system for around $30,000 that includes all “Core Components” of the EnterpriseIQ system, including customer and supplier management, accounts payable and receivable, customer billing), general ledger, alert notification, workflow process approval routing, data export/import, label printing, payroll, and e-mail capability. It also includes manufacturing, production planning/MRP, scheduling, inventory management, receiving and distribution, quoting/estimating, order history and tracking, and more. Shop-floor real-time machine monitoring can be added for $5000. Quality and EDI modules can also be added.

MORE ENHANCEMENTS

Last fall, IQMS released a new version of its Assembly manufacturing type (one of 12 types supported by EnterpriseIQ) that provides greater traceability of types, amounts, and costs of materials and components as well as processes used. It can identify product availability and costs at each stage of production and enhances multi-level bills of materials. Flamm says this new version would appeal to medical device manufacturers.

As we reported last August, IQMS also added a Masterbatch manufacturing type to better support compounders’ needs.

In addition, IQMS launched last year its Automation Div. to develop capabilities for tying in auxiliary equipment such as conveyors, weigh scales, robots, pallet stackers, and stretch-wrappers into the shop-floor reporting functions of the EnterpriseIQ system.

Also new are second-generation wireless sensors for transmitting data within the EnterpriseIQ system. Flamm says this creates a “mesh network with multiple access points,” allowing two-way communication between the ERP system and machine operators. “It’s good for companies that are moving machines around,” he adds.

Related Content

Use Cavity Pressure Measurement to Simplify GMP-Compliant Medical Molding

Cavity-pressure monitoring describes precisely what’s taking place inside the mold, providing a transparent view of the conditions under which a part is created and ensuring conformance with GMP and ISO 13485 in medical injection molding.

Read MoreHow Production Monitoring Can Make You a Better Processor

Real-time information on all your production equipment not only boosts productivity and profitability, but it encourages proactive vs. reactive thinking and sharing of best practices. See how this approach benefited a blow molder with 19 plants.

Read MoreIndustry 4.0 Without Fear: Modular MES Software Lets You ‘Start Simple’ and Add on Later

‘Don’t be afraid of MES.’ App-based platform can start with monitoring just downtime and cycle time on a few machines and add machines and functionality later.

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More