Share

Well maintained, high-quality resin drying systems give you the ability to precisely control four variables:

• Temperature is what gets moisture moving, and selecting the ideal temperature for drying a particular resin is very important. Should you ever be in doubt about an ideal drying temperature, resin manufacturers publish material-specific processing guides online for virtually every material.

• Time is dictated by the size of the drying hopper. These hoppers are specially designed to allow mass flow or first-in-first-out movement of materials. The term “residence time” refers to the length of time that a quantity of resin—either a single batch or each part of a continuous flow—is exposed to the proper drying conditions. When all other factors are well controlled, maintaining consistent residence time will result in consistently dry resin.

• Airflow is what dryers use to transfer heat to the pellets and take moisture away from resin. Recommendations of exactly how much drying airflow is essential may differ from one dryer manufacturer to another. Generally, Conair recommends at least 1/2 cfm/lb of material, representing a “connected” airflow rate that accounts for the “backpressure” of a closed drying system. Of course, a number of factors can affect airflow, such as bulk density of pellets vs. regrind, volume of the drying hopper, and cleanliness of filters.

• Dewpoint is a temperature-based measurement of moisture saturation in air. Volumes of air with very low dewpoints, such as -20, -40, or -60 F, have very low saturation points, so they are very, very dry. But low-dewpoint air that is heated to several hundred degrees in a drying process creates a super-dry airflow with a tremendous capacity to capture moisture and carry it away. So, a dryer that can maintain a consistently low dewpoint creates an environment that won’t be affected by changes in ambient weather, temperature, or humidity. And that’s great for drying consistency.

But, as every processor, manager and operator knows, precisely controlling these four factors is just the beginning. There are a lot more variables to control, including some within, and many outside, the drying process, that will ultimately determine the quality and consistency of your resin drying operations. The tips below explain how to recognize and manage these less-understood variables more consistently and achieve better drying results.

Tip 1: Control Initial Moisture Levels in Undried Resin

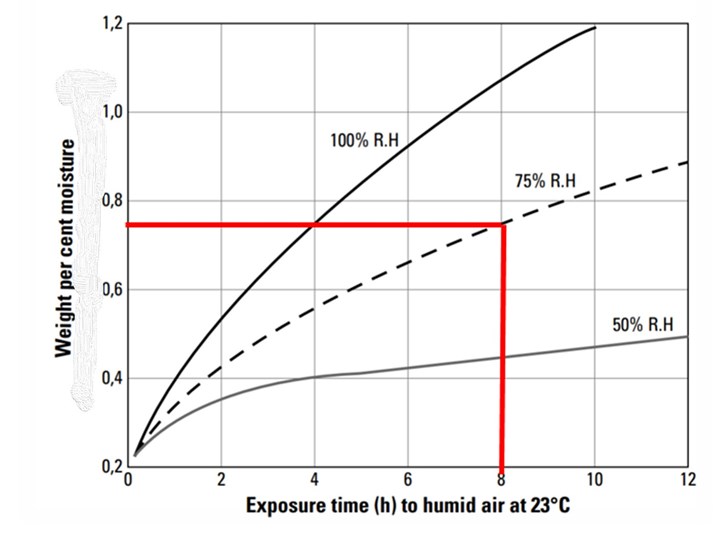

As noted, resin processing guides lay out the finish line for the drying process: the ideal temperature and moisture content of resin that is ready for processing. But the starting line for that process is up to you. It’s determined by three factors: material type, exposure time, and ambient conditions. The chart below, which represents a nylon resin, shows how quickly a hygroscopic material can absorb moisture when exposed to a humid environment. At 75% relative humidity (RH), a nylon like this can go from 2000 ppm to 7500 ppm in a single shift (see Fig 1). That’s a huge change in drying requirements.

FIG 1 Resin manufacturers usually detail the moisture-absorption characteristics of resins in material processing guides. This graph shows how a nylon exposed to 75% relative humidity can go from 2.5% moisture by weight to nearly 8%moisture in just 8 hr.

Of course, if you’re using a polycarbonate or ABS, it will be much more forgiving of exposure to ambient humidity. But the point is the same: It makes sense to store resin so as to minimize exposure to ambient conditions and maintain a relatively constant temperature.

Here are some practices to reduce initial moisture levels:

• Store resin in a central location away from dock doors to avoid constant changes in temperature and moisture levels. Let it acclimate undisturbed.

• Open only the resin you plan to use, one bag or container at a time.

• Seal unused material in bags or boxes.

• Consider foil-lined gaylord boxes for larger unused quantities.

By adopting practices that keep consistent moisture content in all of the resin you use, you’ll minimize large swings in drying times and conditions and increase resin processing consistency and end-product quality. You’ll avoid a common trap—the temptation to “upsize” dryer operations, equipment, and energy usage to deal with extreme initial moisture levels caused by poor resin handling practices.

Tip 2: Size Dryers Properly

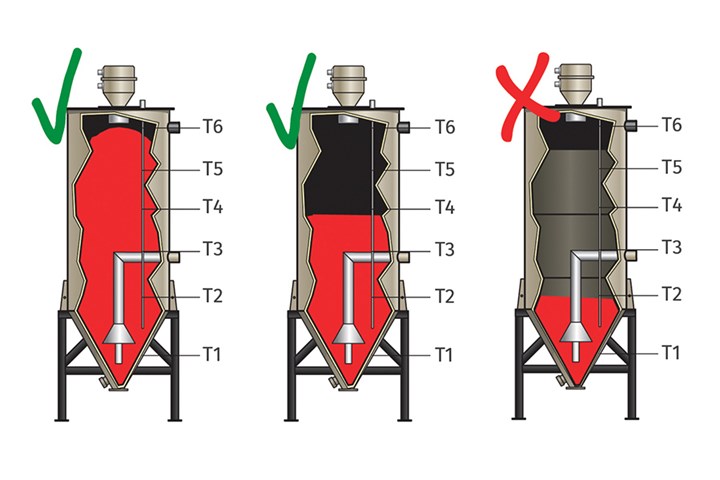

Obviously, you have to size dryers for your maximum requirements, but your minimum throughput should not be less than 50% of the maximum. When you go below 50% capacity, airflow, temperature profile, and mass flow can be affected. Said another way, using oversized hoppers or drying small quantities of resin both have the effect of increasing residence time, since a less-than-full load of resin will be exposed to a full load of heat and airflow. The result is a much higher risk of overdrying or thermal damage (see Fig 2).

You’ve got to size dryers for your maximum requirements, but your minimum throughput should not be less than 50% of the maximum.

Processors are also using more regrind, which can affect drying performance. Most notably, the lower bulk density of regrind materials typically necessitates the use of larger hoppers to maintain the same drying throughput compared with smaller, denser resin pellets. For example, a dryer with a hopper sized to process 1000 lb/hr of pellets simply won’t handle the same rate of regrind. And, as the percentage of regrind increases, the drying residence time should be reduced, due to the lighter total weight of material.

FIG 2 Drying hoppers should be sized for maximum throughput requirements, but minimum throughputs should not be less than 50% of the maximum. Thus, the very small hopper load at right is likely to be overdried and damaged.

Think of the difference between feathers (regrind) and pebbles (pellets): It takes a much larger vessel to capture the same weight of feathers as it would pebbles or stones. In addition, drying airflow and moisture removal in regrind behave differently due to the shape of the flakes. So, if you’re having trouble working with regrind—or experiencing processing problems that could be due to moisture—contact your drying-equipment vendor for help in determining the proper sizing of dryers and hoppers to work with your application.

Another issue is to match the dryer to the hopper. We recommend dryer/hopper combinations that deliver a minimum of ½ cfm/lb of material at a velocity of between 20 and 40 ft/min. Again, those numbers are based on a “connected” system. This is important to note, since not all equipment suppliers rate their systems in the same way.

One other thing: It can be tempting to utilize existing equipment, maybe by matching up a spare dryer with a spare hopper, even if they aren’t well matched. Let’s say you have a dryer capable of 1000 lb/hr but you have a hopper that was only sized to run 200 lb/hr. The dryer has more than enough capacity, but this combination is going to cause problems.

For example, the dryer is going to put out a volume of air (and heat) suited to a full resin load in a large, properly-sized hopper (e.g., ½ cfm/lb at 20-40 ft/min velocity). If that airflow gets pushed through a smaller-diameter hopper, the velocity of that air is going to increase dramatically. If excessive airflow began to fluidize the material, it would make it very difficult to keep the hopper properly loaded, since material will want to exit with the airflow through the hopper outlet. Conversely, a small dryer on a very large hopper would produce a poor result due to lack of proper airflow and insufficient drying energy.

Tip 3: Dry at Correct Temperature

Every material has an ideal drying temperature, as prescribed by the resin manufacturer. While there is a subset of materials (e.g., RPET) that will tolerate “low and slow” drying—a longer residence time at a lower temperature—others (e.g., nylons) may never reach target moisture levels without exposure to the specified drying temperature. Similarly, trying to speed up drying using higher-than-recommended temperatures is also problematic due to the risk of overdrying or thermally damaging the material.

Take nylons for example. Because their moisture levels can get very high, up to 8-9%, it might seem appropriate to increase the drying temperature to reduce the drying time. However, increased heat can cause thermal damage—brittleness, yellowing, or other color changes (see Fig. 3). As mentioned in Tip 1, you are much better off if you can limit initial moisture content of the material through smart material-handling practices. Doing that is the best way to ensure that you can dry resins consistently without the risk of working outside of the manufacturer’s material recommendations.

Trying to speed up drying using higher-than-recommended temperatures is problematic due to the risk of overdrying or thermally damaging the material.

FIG 3 Four samples of identical nylon: The sample at left retains its natural color, demonstrating proper drying, while the samples to the right demonstrate overdrying, resulting in increasing levels of thermal damage and yellowish discoloration.

Tip 4: Keep Drying Hoppers Full

In a continuous drying process, achieving a consistent residence time for all material depends on keeping the hopper level even and maintaining a continuous flow: Finished material out should equal new material in. Because material level in the hopper is tied to residence time, any reduction in the hopper level reduces residence time and causes inconsistent drying. And, unless you have reduced the hopper level by design to limit residence time, this could become an issue.

Put another way: Don’t batch load a continuous system. If you allow a hopper that dries material in 4 hr to run halfway down before topping it off, the first part of that newly loaded material is only going to have 2 hr of residence time. It’s going to be under-dried, causing possible problems with production.

Don’t batch load a continuous system.

To get continuous material flow and consistent residence time, use an integrated, motorized hopper loader or central conveying system. While hand loading smaller systems seems like an easy way to tackle this issue, it is very inconsistent and will take constant monitoring. Another good use of technology is to take advantage of the monitoring and control features of newer dryers:

• Use a level sensor to keep material topped off and ensure you’re getting a good fill.

• Use a hopper temperature probe, such as a Conair Drying Monitor, to ensure a uniform spread of temperatures, reflecting a uniform airflow and material inflow from hopper bottom to top. If someone attempts to batch load a large amount of “cold” material at once, a sensor like this one would detect the temperature change and signal a “low temperature” alarm, enabling you to make adjustments to prevent underdrying.

• Use temperature setback technology that detects increases in return-air temperatures and automatically reduces dryer temperatures to a lower standby level to slow down drying or prevent overdrying.

Tip 5: Limit Machine-Side Material Inventory

As a rule, you should limit the amount of material that you keep outside a dryer, ready for processing, to about a 15-20 min supply. That means, for example, that it is not a good practice to dry material, then load it into an undried machine hopper that can hold 1 to 2 hr of inventory. That’s going to expose that material to temperature loss and moisture regain and expose your process to variations in production quality.

Limiting machine-side material inventory is a great way to maintain process consistency.

You can adapt this rule according to the material types and ambient conditions; but overall, limiting machine-side material inventory is a great way to maintain process consistency.

Tip 6: Keep Airflow Clean and Consistent

A desiccant dryer has three critical filters: process air, aftercooler, and regeneration (see Fig. 4). Regularly monitoring and cleaning all three keeps drying airflow running smoothly, eliminates system and desiccant contamination, and prevents overheating. At the same time, regular inspections of dryer hoses and connections for kinks, breaks, or delamination prevents process leakage, energy loss, and poor drying results.

FIG 4 Positions of three types of filters on a typical mobile desiccant dryer. All air filters should be inspected and cleaned regularly to assure consistent drying temperature and airflow.

Tip 7: Invest in a Moisture Analyzer

Moisture analyzers aren’t inexpensive. But neither is the guesswork, effort, and lost production that occurs when you—or all of those you call for help—struggle to identify the cause of a process or quality problem. You’re left wondering: Is the issue due to material supply, drying, or some factor at the machine or mold? Having a moisture analyzer will pay for itself because it offers a quick and reliable answer regarding moisture problems.

If an analyzer check shows a material moisture problem at the machine, you can go back and test the initial moisture level of materials before they enter the drying process. If those initial levels are unusually high, you can quarantine suspect materials and correct material storage practices. If initial moisture is normal, you can troubleshoot your drying equipment, knowing that it is the probable source of the problem.

For maximum precision with an analyzer, use a consistent sampling technique:

• Use identical vessels that can be sealed (i.e., glass jars with lids);

• Completely fill sample vessels, leaving no air space;

• Test two samples of each material to reduce variability.

Success in resin drying—and plastics processing—is all about achieving and maintaining consistency. The tips above offer seven well-proven, actionable ways to eliminate common mistakes and operate more efficient, consistent, and productive resin drying operations. As you’ve seen, drying success isn’t just about the quality, features, dewpoints, or alarm settings of the equipment you use. It’s also about what you do by recognizing and managing material characteristics, limiting the impact of the ambient environment, and investing in automation and work aids to eliminate variables and make better-informed decisions. There’s no doubt that good equipment and timely supplier advice are very important to drying success. But ultimately, it’s good management that makes the difference.

About the Author: Anthony “A.J.” Zambanini is product manager for Drying at Conair Group, with responsibility for continued development and innovations involving Conair’s dryer product line. Before joining Conair in 2014, Zambanini was a former customer with responsibilities for product management, plant engineering and capital improvements. He graduated from Penn State in 2010 with a degree in mechanical engineering and a minor in technical sales. Contact: 724-584-5558; azambanini@conairgroup.com; conairgroup.com.

Related Content

AI Manages Resin Drying Airflows and Throughputs for Energy Savings

NPE2024: Optional feature automates the process of maintaining process-ready resins at perfect temperatures and varied throughputs, while preventing overdrying and realizing significant energy savings.

Read MoreFinding Efficiencies in How Components Work Together

Auxiliary systems are vital to the proper functioning of a plastic processing line, and they can be a source of major cost and efficiency improvements.

Read More'Smart,' Moisture-Based Drying Technology Enhanced

At NPE2024, Novatec relaunches DryerGenie with a goal to putting an end to drying based on time.

Read MoreService Enables One-Day Auxiliary Commissioning

One-day, on-site equipment setup and training assistance program for all types of Conair auxiliaries.

Read MoreRead Next

What You Need to Know About Drying Specialty Nylons

PPA is being used more frequently by molders for demanding high-heat applications in automotive and other markets. While in the nylon family, it does not dry quite like nylon. Follow these tips.

Read More